Wolfspeed adds additional SiC manufacturing capabilities

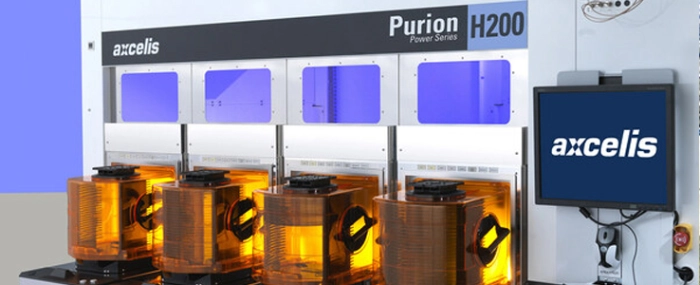

Axcelis has shipped a Purion H200 SiC ion implant system to SiC specialist Wolfspeed. The evaluation system will be used to support the production of power devices for EV applications.

“The power device market continues to grow rapidly and is a key driver of our growth globally. We are pleased to continue to support Wolfspeed’s fab capacity expansion and are also excited about the potential of this new opportunity focused on high current implant applications in silicon carbide power devices,” says President and CEO Dr. Russell Low of Axcelis in a press release.

Wolfspeed is currently engaged in a USD 6.5 billion capacity expansion effort to dramatically increase production. This includes the John Palmour Manufacturing Center for Silicon Carbide, the world’s largest silicon carbide crystal growth facility currently under construction in North Carolina, and the final build-out of the company’s Mohawk Valley Fab in New York. Earlier this year the company also announced its plans to build a highly automated, cutting-edge 200mm wafer fabrication facility in Saarland, Germany.

“The popularity of electric vehicles is only steepening, and Wolfspeed is focused on scaling our capacity to meet the surge in demand for our silicon carbide devices. We partnered with Axcelis due to their expertise, highly differentiated features, and process control capabilities that are essential for power device applications,” says Missy Stigall, Wolfspeed senior vice president of global fab operations. “Together, we will work to ease supply chain constraints as more and more EVs utilizing Wolfspeed’s silicon carbide technology are introduced to the market.”