2022 will see a focus on 12-inch capacity expansion

TrendForce says that global wafer foundry capacity will increase by approximately 14% annually in 2022.

Since expanding 8-inch capacity is not cost-effective and its growth rate is much lower than the overall industry average, 8-inch capacity will grow approximately 6% annually, while 12-inch capacity will grow 18% annually. Of this new capacity, approximately 65% of new 12-inch capacity will be in mature processes (28nm and above) with an annual growth rate of 20%. It is obvious that in 2022, most wafer foundries will focus on 12-inch wafer production capacity, with the main driving force behind production expansion coming from TSMC, UMC, SMIC, HuaHong Group’s HHGrace, and Nexchip.

As the recent expansion activities of process nodes above 28nm focus on the diversified development of specialty processes, TrendForce has analyzed the recent trends of these specialty processes based on products such as Power-related, MCU, and AMOLED driver ICs. First, power semiconductors can be roughly divided into two categories: power discrete and power IC. Power discrete, with power transistors such as MOSFET and IGBT as mainstream products, is affected by 5G infrastructure, consumer fast charging, automotive electronics, and electric vehicles where the consumption of power components per unit of product has increased and demand has grown rapidly. The overall market has long been dominated by international IDMs, such as Infineon, On Semi, and STM. Global IDMs account for approximately 80~90% of the market while fabless firms account for approximately 10~20%. In terms of foundries, in addition to increasing demand from existing fabless customers, due to the relatively conservative expansion process of IDMs’ own factories in recent years, capacity shortages have been commonplace and IDMs have also successively outsourced products to foundries. HHGrace's power discrete revenue scale in 2021 was the greatest in the pure-play foundry field with the steady release of new 12-inch capacity in Wuxi to perpetuate revenue performance. PSMC and Vanguard have also recently increased their 8-inch capacity to undertake related orders.

In terms of PMIC, BCD (Bipolar-CMOS-DMOS) platform technology has mostly been adopted at this stage and mainstream manufacturing is performed at the 8-inch 0.18-0.11µm nodes. Benefiting from upgraded technical specifications for 5G smartphones, data centers, and electric vehicles, demand for PMICs has spiked in recent years. However, due to limited growth in 8-inch production capacity and the need to update peripheral ICs in response to the release of a new generation of SoCs, each foundry has also successively assisted clients in migrating certain PMICs to 12-inch production. The plan is to migrate these PMICs to the 90/55nm nodes, focusing on applications such as smartphones and servers. TSMC, UMC, PSMC, HHGrace, and SMIC, all have such plans.

The eNVM (embedded Non-Volatile Memory) process possesses relatively diversified technology and eFlash is currently its mainstream process. In addition, eNVM process applications are mostly used in smart cards and MCUs. An MCU has a wide range of uses. For example, industrial/automotive and consumer electronics such as information communication products, home appliances, and IoT products requiring simple functional commands to diverse complex applications, will use MCU components. In addition, embedded memory technology for MCU will also vary based on slight differences in functionality. Although the demand for consumer MCUs is relatively flat due to weak market conditions, MCU stocking momentum to meet automotive and industrial equipment demand is still strong, leading to a relative shortage of MCUs in the currently market. In addition, IDMs have been increasingly outsourcing orders driven by the short-term consequences of the pandemic on the supply chain and the cost factors of MCU products moving to more advanced process nodes in the medium and long term, especially as the cost of expanding processes below 40nm (inclusive) has increased significantly. This, in turn, stimulates the MCU application development and deployment of wafer foundries. With an earlier mass production for processes below 40nm (inclusive) and process maturity, Taiwan's foundries have also accepted orders from IDMs, while the technology utilized by SMIC and HHGrace lag by approximately one generation, though HHGrace possesses the greatest production capacity among Chinese foundries.

HV (High Voltage) process technology is mainly used in the production of display driver ICs. At present, the mainstream includes the production of large/small size driver ICs at the 8-inch 0.18-0.11um process nodes, the production of TDDI at 12-inch 65/55nm, and the production of smartphone AMOLED driver ICs at 40/28nm. Since the beginning of 2022, smartphone and consumer electronics market conditions have continued to be sluggish, balancing the supply of large-size driver ICs and TDDI. However, since the overall penetration rate of AMOLED in mobile phones is still rising steadily, continued growth momentum is forecast in the medium and long term for AMOLED driver ICs. Samsung, TSMC, UMC, and SMIC all have plans to develop 28nmHV. The process technology of remaining players including HHGrace or Nexchip remain dominated by the 65/55nm nodes and they have yet to be able to mass produce AMOLED driver ICs.

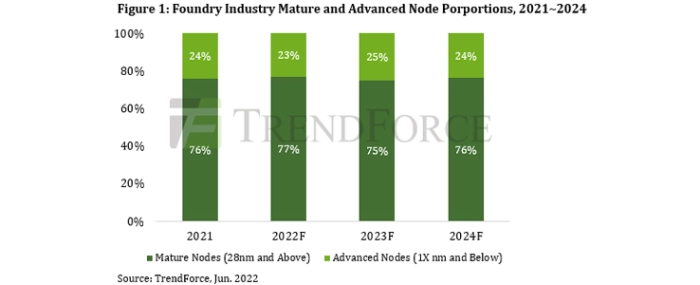

According to TrendForce investigations, the compound annual growth rate of global foundry capacity will reach 11% from the period of 2021-2024, of which 28nm capacity in 2024 will reach 1.3 times that of 2022, the most active process node for mature process expansion. More specialty process applications are expected to be migrated to 28nm and the global production capacity of mature processes above 28nm (inclusive) will stably maintain a 75-80% proportion of overall production capacity from 2021 to 2024, showing the market potential and importance of creating specialty mature processes.

At the same time, TrendForce indicates, due to the impact of the pandemic on the global supply chain and geopolitics, regional "short-chain production" and supply chain autonomy have become key considerations for foundry expansion. For example, in order to ally with regional production and improve the flexibility of capacity scheduling, Taiwanese foundries have corresponding expansion plans in the United States, Japan, China, and Singapore. Except for TSMC's U.S. fab, which focuses on advanced processes, remaining expansion plans focus on specialty process technologies. In addition, recent expansion activities clearly show that foundries in mainland China are actively expanding mature process technology and capacity. These companies are allocating the production of key peripheral ICs such as HV, MCU, PMIC, and power discrete, in order to enhance the autonomy of their supply chains and meet the needs of the domestic automobile, consumer electronics, and information and communication industries.

For more information visit TrendForce.