Foundry market expected to drop 6.5% YoY in 2023

The global semiconductor foundry market grew 27.9% YoY in 2022. However, it is projected to decrease by 6.5% YoY in 2023 due to inventory adjustments, according to IDC.

According to IDC’s Semiconductor Manufacturing Services: 2022 Worldwide Foundry Market: Vendor Ranking and Insight, the global foundry market size grew by 27.9% in 2022, hitting a new record high, benefiting from customers' long-term agreements (LTAs), higher foundry prices, process shrinkage, and plant expansion.

"The foundry industry plays a key role in the semiconductor supply chain. The top 10 vendors all reported double-digit revenue growth in 2022. However, due to changes in market conditions, order revisions had led to a sharp drop in the capacity utilisation of foundries in the last three quarters,” says Galen Zeng, Senior Research Manager, Semiconductor Research, IDC Asia/Pacificm, in a press release.

Zeng continues to say that there is still rigid demand for semiconductors in the market and that it is expected that after the supply chain experienced more than one year of de-inventory subsequent order planning will turn from being negative to steady and conservative. According to the Senior Research Manager, this coupled with the AI boom will slowly drive a recovery in capacity utilisation of 5%–10%.

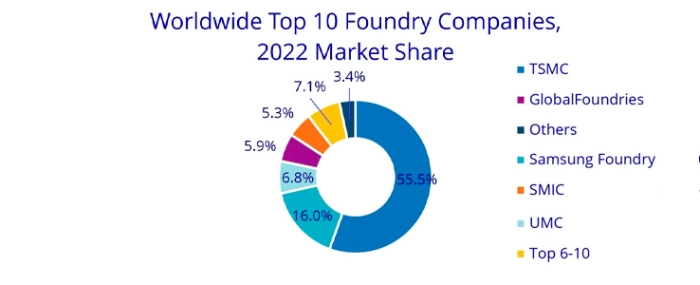

Looking back at 2022, the foundry industry performed well. Among the top 10 semiconductor foundry vendors are "the regular suspects" such as TSMC, Samsung Foundry, UMC, GlobalFoundries, SMIC, HHGrace, PSMC, VIS, Tower, Nexchi.

The leading vendor, TSMC, has its advanced processes continued to evolve, with its market share increasing from 53.1% in 2021 to 55.5% in 2022. Driven by the recent gradual increase in orders for 3/4/5nm wafers, TSMC's market share is expected to pick up further in 2023.

In addition, Chinese foundry vendors actively developed mature processes, gaining a total market share of 8.2% in 2022, compared with 7.4% in 2021, in addition to their respective revenue growth of over 30%. Observations based on the capacity utilisation show that IC designers had actively stocked up till the first half of 2022 (1H22), and the signing of long contracts further promoted the foundry price to remain robust and the capacity utilisation to reach 90%–100%. However, from the second quarter of 2022 (2Q22), the supply chain operations grew increasingly cautious and IC designers reduced orders with foundries, including drastic cuts in orders for some consumer ICs and cancellations of LTAs on them, resulting in top-heavy operations throughout 2022.

In 1H23, the purchase intentions for consumer electronics were low, and market demand showed no significant increase, IDC reports. Inventory adjustment for endpoint products will continue into the second half of the year. Although orders for AI- and high-performance computing (HPC)related wafers are abundant, some IC designers' products will also experience de-stocking and have inventory replenishment in 2H23. Demand for inventory is not all that optimistic amid the decline in LTAs and the fading price rise dividend.

Considering the high baseline of the previous year, IDC expects the worldwide foundry market size to drop slightly by 6.5% in 2023. The foundry segment will fall slightly compared with the overall semiconductor supply chain, and the whole industry is projected to get back on track in 2024.

For more information visit IDC.