AI vs. Reality – does AI need a lunch break?

Nowadays it is hard to find someone who hasn’t heard about Artificial Intelligence. The term is still thrown around in various contexts as a universal remedy, meant to instantaneously and effortlessly solve complex problems in which the classical algorithms fail miserably. But is that really the case?

Sadly, this stance could not be further from the truth, that is what the AI experts at Polish technology company Fitech says.

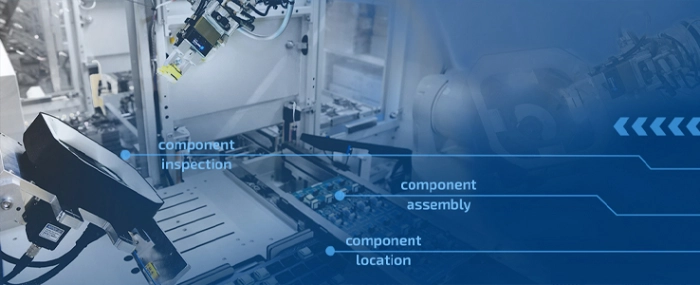

So, why use AI at all in when it comes to the optical inspection of PCBA?

“The classic approach to optical PCBA inspection is to rigidly define parameters for a specific case, for example, we define that in this place the picture should be a red area with a round shape. ‘Rules’ like this should be defined for each component on a PCBA, and there may be even several thousand elements. In the AI-based approach, we would only need to tell the algorithm how the component examples look like. The only disadvantage is that we have to provide several hundred of these examples. But on the other hand, we do not have to ‘manually’ define what the inside of such an element looks like, but tell the algorithm ‘this is what the component looks like, learn how it looks’,” says Grzegorz Kałucki and Kamil Jarosz, Artificial Intelligence Specialists at Fitech.

What would you say are the greatest limitations of AI when compared to humans in this instance?

“A man will quickly learn to examine specific cases. For example when you tell a production employee that he should check whether ‘the yellow ribbon on the D202 component reach the laminate when looking at a 45-degree angle’ – it will be almost immediately understandable. A model based on AI however needs to be given a lot of examples to learn how to handle such a case,” Kałucki explains and continues.

“On the other hand, an AI model doesn’t get tired and will not become distracted, so after the lunch break it will be as good at detecting errors as it was before the lunch break; unlike humans. In summary, humans will be better in individual, specific cases, while AI will be better in repetitive, mass cases.”

What are the most important and most difficult tasks for engineers related to optimising AI systems for optical inspection?

“Data acquisition, data tagging, scaling, making and validating hypothesis... the list is long,” the specialists says.

For anyone interested in the topic, Fitech hold a presentation called Artificial Intelligence meets Real World – AI-based PCBA optical inspection during Evertiq Expo Berlin on 2 June 2022.