© Universial robots

Electronics Production |

Universal Robots drives cost savings at PSA Group

PSA Group – the European car manufacturer – is increasing its factory performance and reducing production costs as part of its “Excellent Plant” initiative, utilising Universal Robots (UR) to help drive the project.

The results of the new robotic assembly system include improved worker ergonomics and cost savings of two to eight Euros per car, which represents up to EIR 400’000 to EUR 1.6 million in initial cost savings. The automated UR robot system also aids producibility through a 10% improvement in geometric dimensioning and tolerance (GD&T).

“We chose the UR10 robot for its reach, ease of programming and safety, but we’ve been extremely impressed with how quickly this initiative paid for itself,” said Cedric Grandjean, Architect Element Specialist, Finish Assembly Line at Groupe PSA. “Typically, when we implement new robots, we expect an initial loss in production that is made up over time, but that didn’t happen in this case. In fact, our return on investment has been between six months and one year, depending on the site where the robots are deployed.”

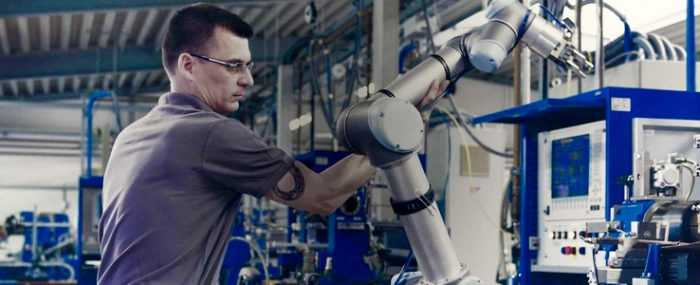

Group PSA first updated its site in Sochaux, France, which manufactures 400’000 vehicles per year, with a new assembly line that incorporates UR10 robots in a unique collaborative screw-driving operation. The robots are mounted on a moving platform that goes under the vehicle in production. Operators pull the vehicle into place and the robot manages the ergonomically challenging screw-driving operation under the vehicle while the workers continue with other assembly tasks.

The entire system was implemented throughout the Sochaux site in only eight months. Group PSA has since filed national and international patents for the entire unique application, including the integration of the UR10 robots, deploying the system throughout its European plants in France, Spain and Slovakia.