© Evertiq

Electronics Production |

TV: Assembléon's iFlex hits the market

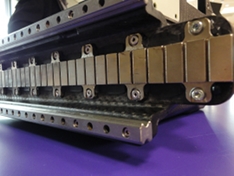

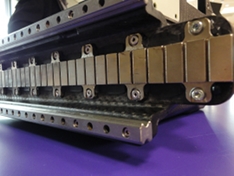

Dual transport lanes, dual sided feeding, internal buffer positions and feeder trolley exchanges during production: Dutch equipment manufacturer Assembléon has launched its iFlex into the market.

© evertiq

Using single-pick / single-place technology, Assembléon promises "the industry´s highest First Pass Yield production levels with defect levels of less than 10DPM".

"Electronics manufacturers, especially in Europe and the SAmericas, are seeing a growth of their product mixes. But a wider product variety also means a risk to productivity. Changing from product A to product B takes time and therefore money. iFlex reduces this risk by offering a smart combination of flexible hardware and software solutions", says Tonn van de Laar, CEO Assembléon.

"Electronics manufacturers, especially in Europe and the SAmericas, are seeing a growth of their product mixes. But a wider product variety also means a risk to productivity. Changing from product A to product B takes time and therefore money. iFlex reduces this risk by offering a smart combination of flexible hardware and software solutions", says Tonn van de Laar, CEO Assembléon.

Featuring dual transport lanes, dual sided feeding, internal buffer positions and feeder trolley exchanges during production, iFlex is designed for highest throughput. Building on well-established know-how, the iFlex adds flexibility to proven technology. The 'Independent Dual Lane' concept allows manufacturers to produce in volume on one lane, while changing jobs on the second. Three modules make for tailor-made assembly lines - from 1 to more than 8 modules - catering for any manufacturing need. - iFlex T4 for chip and small IC shooting (4 placement robots, placement speed of 51'000cph, 128 twin tape feeder positions) - iFlex T2 catering for flexible placement needs (2 placement robots, placement speed of 24'000cph, 128 twin tape feeder positions) - iFlex H1 for ICs and fine pitch placements (1 placement robots, placement speed of 7'100cph, max 146 twin tape feeder positions / max 30 tray positions)Featuring dual transport lanes, dual sided feeding, internal buffer positions and feeder trolley exchanges during production, iFlex is designed for highest throughput All photos © Assembléon

"Electronics manufacturers, especially in Europe and the SAmericas, are seeing a growth of their product mixes. But a wider product variety also means a risk to productivity. Changing from product A to product B takes time and therefore money. iFlex reduces this risk by offering a smart combination of flexible hardware and software solutions", says Tonn van de Laar, CEO Assembléon.

"Electronics manufacturers, especially in Europe and the SAmericas, are seeing a growth of their product mixes. But a wider product variety also means a risk to productivity. Changing from product A to product B takes time and therefore money. iFlex reduces this risk by offering a smart combination of flexible hardware and software solutions", says Tonn van de Laar, CEO Assembléon.