Fabric8Labs secures $50M to expand US manufacturing capacity

Fabric8Labs, a developer of Electrochemical Additive Manufacturing (ECAM) technology, has secured USD 50 million in funding to expand its US-based production facilities, enabling the company to produce up to 22 million components annually.

The financing round was led by NEA and Intel Capital, with participation from Lam Capital, TDK Ventures, SE Ventures, and new investors including Marunouchi Innovation Partners, SK hynix, Ericsson Ventures, Masco Ventures, and Toppan Global Venture Partners.

The funding will support the expansion of Fabric8Labs' manufacturing footprint, ramp-up of production capacity, and growth of teams across manufacturing, design, quality, and process engineering. The company produces next-generation components for thermal management, wireless communications, and power electronics, with applications in AI/HPC systems, RF devices, and electrified vehicles.

"This investment accelerates our mission to scale Electrochemical Additive Manufacturing (ECAM) for customers in high-growth, fast-moving industries where we are solving their most demanding challenges. With ECAM, we're reshaping how critical components are designed and manufactured—delivering the performance, reliability, and supply chain resiliency that enables customers to rapidly innovate and deploy advanced systems," says Jeff Herman, Co-Founder and CEO of Fabric8Labs, in a press release

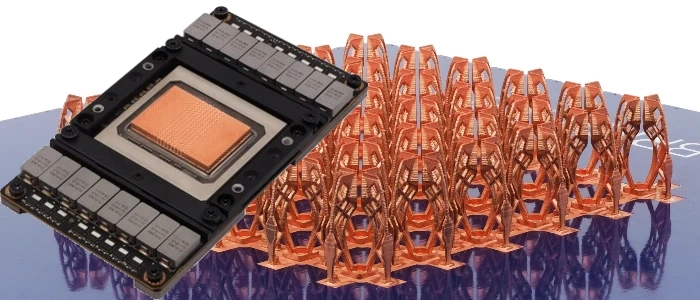

Fabric8Labs’ ECAM technology is a room-temperature metal additive manufacturing process that uses electroplating principles to produce high-resolution 3D metal parts without costly post-processing. The platform supports rapid production of complex components – at the atomic level.

In thermal management, ECAM enables advanced cooling solutions for AI and HPC chips. In wireless communications, the technology allows fabrication of 3D antennas directly onto PCBs and high-performance substrates, optimising size, weight, power, and cost for applications including satellite constellations and mobile networks. In power electronics, ECAM produces high-current interconnects and passive components for electric vehicles, reducing assembly steps and material interfaces.

"Early on, we recognised the potential of ECAM to deliver unmatched precision, scalability, and design freedom—unlocking new opportunities across thermal management, aerospace, and power electronics. We're thrilled to continue supporting the team as they expand U.S. production and scale this transformative platform," says Greg Papadopoulos, PhD., Venture Partner at NEA.

.jpg)