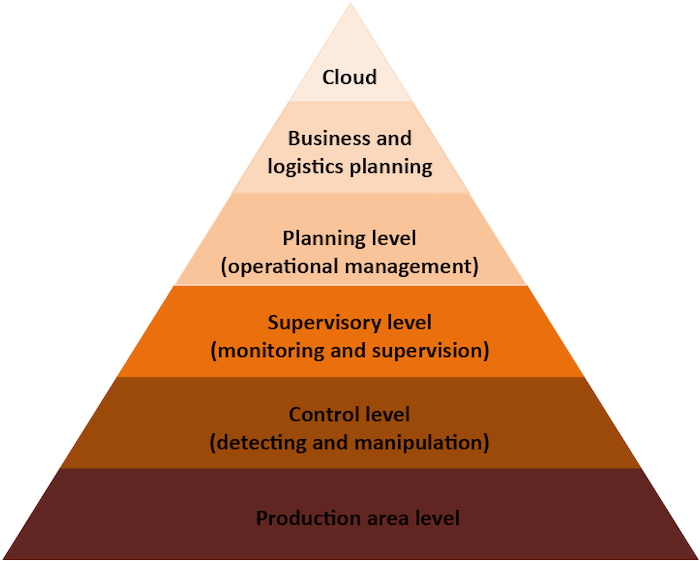

Automation pyramid in Industry 4.0

It is believed that the first industrial revolution started with the invention of the steam machine. The onset of the next revolution was related to inventing electricity and combustion engines, which facilitated the automation of numerous production processes and streamlined the transport of manufactured goods. The third stage of the industrial revolution resulted from the development of digital technology, i.e. inventing inexpensive computers, mobile phones, and the Internet. It started in the second half of the 20th century and spurred the fourth stage of the revolution we are witnessing today.

IoT and IIoT

Differences between IIoT and M2M

Automation pyramid

Supply-based implementation

The fourth industrial evolution is closely related with the Industry 4.0. Similarly to the previous consecutive stages, this one, too, is linked to the introduction and dissemination of new technology applications. In this case, the process has encompassed industrial robots, artificial intelligence, the Internet of Things and its subset, i.e. Industrial Internet of Things. On the other hand, it is not only technical inventions that have caused the 4th industrial revolution, as the social changes and environmental concerns have certainly played a part, too. However, leaving the philosophical considerations aside, let us focus only on the technical aspects and solutions that can help us with the individual tasks fulfilled by industrial applications.

It seems that the invention of the Internet as a global network of devices providing an unprecedented possibility of cheap communication and access to expertise and information across the various division lines was what has spurred all the changes taking place nowadays (not only in field of technology). Initially, the Internet was used mainly for the users’ communication purposes. Next, access to the multimedia was provided and, eventually, data obtained from various sensors started to be sent over the global network. Here, a problem occurred, as the Internet is perfectly adjusted to transmit large data sets, but has problems handling small data packages obtained from sensors, i.e. usually containing from several bits to several bytes. On the Internet, such a package must be accompanied by certain additional data, such as the header and the checksum, which in this case is redundant and often takes up more space than the actual measurement results sent by a sensor. Other issues include the time it takes for such data to reach the recipient and whether it reaches them at all, as in extreme cases it can travel over a very long distance or get lost. Sometimes, it reaches recipients with a delay of several seconds, which is not a problem while monitoring a cargo container being shipped from port “A” to port “B”, browsing websites or sending an email, but is unacceptable for most industrial applications. It is still useful at the global process management or monitoring level, but it is not suitable for the production process supervision and control.

All in all, those involved in industry and manufacturing processes found the idea of harnessing the global network to operate industrial plants or logistics processes related to goods supply and transport really compelling. Therefore, new technologies have been developed as Internet subsets, i.e. the Internet of Things (IoT) and Industrial Internet of Things (IIoT). How do they differ from the Internet and why have they been treated as separate from it?

Internet of Things (IoT) and Industrial Internet of Things (IIoT)

The Internet of Things (IoT) is a network comprising interconnected devices (mostly sensors) which require transmission of small data packages. Note also that various sensor network standards are very well equipped for the transmission of a few or several bytes of sensor data via transmitters supplied with open-access energy. In numerous applications, the sensor interface saves or stores energy by remaining dormant for long periods of time, to be woken up from the stand-by mode as per a fixed schedule, due to a certain operation frequency, or as required.

Individual devices included in an IoT network can communicate with each other and share data over the Internet. Depending on individual needs, they can be connected via networks with different topologies. Importantly, such connections are based on various standards promoted by independent manufacturers. In numerous applications, a mesh network is used, which greatly increases the coverage. It also comes with a redundant connection mechanism, where data is transmitted by radio, through nodes and to a hub. However, mesh networks are not the only solution available, and sensors can also be connected using a tree or mixed topology network structure. There, sensors share data on demand or compete for access to a hub.

While the sensors themselves are not overly complex and can communicate over an internal standard, the hub that bridges them to the Internet must translate all data correctly and use it to form standardised packages. IoT devices are used to collect and analyse data, and automate its processing in various fields, including energy production and distribution, illumination control and monitoring, as well as monitoring transport, weather conditions, rivers or healthcare applications. IoT applications involve diverse interface types, there are plenty of them, and it is to be expected that the designers’ inventiveness will still result in new uses, especially considering the fact that IoT can be and is associated with consumer devices.

The Industrial Internet of Things differs from its prototype primarily in its application area. It spans a network of interconnected industrial sensors that can not only communicate with each other and determine, asynchronously, the starting moments of various manufacturing process stages, and also monitor those processes in real time to assist the machinery operators and managers in ensuring even better factory performance. Information from the individual management systems or sensors can be integrated and evaluated by cloud-based software, with AI-driven deep learning or process management algorithms. Such systems ensure a high level of integration of logistic processes with production processes, which results in the company’s increased profitability and competitiveness.

The IIoT technology bridges the gap between the operating and information technologies, facilitates connecting industrial processes and their managing systems within a network, and is a key tool supporting the Industry 4.0 revolution.

Do not confuse it with M2M!

While discussing IIoT, we must mention machine-to-machine (M2M) communication, as its development has been critical for the IIoT. M2M used to refer to user interfaces, but currently this term is mostly used when speaking about machine-to-machine connections. Note also that even if a human is the recipient of machine-generated information, it is still sent via a translator of some kind, which is, in fact, a machine, so we still deal with machine-to-machine data transmission here.

M2M is a technology developed for sending data between machines or between a machine and a gate, in a point-to-point topology. The gate can be attached to a company’s network or to a global network, e.g. a mobile telephony operator. In certain applications, especially where data conversion is required, the gate can also facilitate machine-to-machine communication.

The M2M technology is quite difficult to scale. It is particularly recommended when communication must be well protected against unauthorised access, and increased reliability is required. For example, communication with another machine or the operator must be possible even when an internal network or the Internet connection is unavailable. In contrast to IIoT, the M2M communication does not facilitate synchronising numerous devices in real time or controlling them via cloud-based applications. In contrast to IIoT, where it would have to ensure compatibility with various standards or make global standard conversions, it is also limited to a certain data-exchange standard. As a result, M2M devices are not data sources for the company’s ERP, PLM or SCM software.

Differences found in these two communication types result in the fact that their applications are also different. The M2M technology is primarily concerned with machines, equipment, and end devices such as smartphones or tablets, while IIoT is related to digital device systems such as sensors. In the industry, M2M is mostly used for maintenance purposes to alert operators about possible machinery defects, maintenance deadlines or damage, while IIoT is used to integrate large systems. Note also that M2M is more hardware-focused, and IIoT is software-focused.

M2M communication is designed to control a single industrial machine or a cluster of machines. It is possible via radio or wired communication using specialised M2M hardware modules. Control is provided by a specialised unit sending commands and receiving data by means of point-to-point transmission, as mentioned above. The IIoT systems use the Internet to send data from sensors or devices to the cloud, where numerous services and applications can be run.

The IIoT and M2M concepts share the same roots, as they refer to the same device group. However, the IIoT provides additional capabilities in applications where the traditional M2M systems fail. The IIoT systems facilitate data sharing across a company to extract business data and manage operations more efficiently. Moving from closed silo deployments to multi-functional open IIoT technologies facilitates the integration of the sensor and device data with other company’s applications such as Big Data and analytics. The M2M systems decode issues at the machine level or for the enhancement of the device performance, while the IIoT systems leverage big data and analytics to achieve company-wide improvements.

The M2M systems reduce expenses thanks to features such as remote diagnostics, upgrades and remote troubleshooting to minimise effort related with deploying field service engineers to faraway locations. On the other hand, the IIoT systems focus on operational improvements and deliver information solutions as a cloud service. In other words, IIoT means departing from hardware (connectivity and devices) to software (services, practical expertise and data) to improve operations.

Automation pyramid in a company

Technologies related to M2M, IoT or IIoT might be sufficient to automate the production processes, but they will not start the revolution mentioned in the introduction to this text. What brings revolution is new ideas that question the status quo and suggest alternative solutions. While planning company automation along the lines of Industry 4.0, it is worth analysing a diagram that is commonly presented as the automation pyramid. Its levels are described below.

Level 0 – Production area level/Production process

Level 0 includes devices, actuators and sensors deployed within the production process area. This area should not be equated only with a production floor, as often flow control valves are mounted outside it, for example, on the outflows of tanks that supply raw materials for production, mounted outside the facility. Other examples include electric pump motors, hydraulic and pneumatic actuators, proximity switches for detecting objects or their movements, and photoelectric switches performing a similar function, etc.

Level 1 – Control level/Detecting and manipulation

At this level, physical objects are manipulated and processed. Here, PLCs and PID regulators are controlled. Attached tools and manipulators perform the actual processing using a variety of technologies. The PLCs and PID regulators download information from sensors, switches and other input devices to select outputs to be activated in order to complete the programmed task.

PLCs are equipped with a CPU, storage for programming and other data, plus input and output modules. PID regulators are usually integrated with a PLC or come in a form of a program executed by a PLC. PIDs often control temperature in industrial processes, as numerous manufacturing processes require heating, cooling, and maintaining a certain acceptable temperature fluctuation margin.

Level 2 – Supervisory level/Monitoring and supervision

Level 2 is a supervisory level. It uses the SCADA (Supervisory Control And Data Acquisition) software. SCADA combines the previous levels that facilitate data access and production process management with systems facilitating control from a single location. A graphic user interface for remote function control is usually installed at this level. In this way, SCADA makes it possible to monitor and control numerous systems from a single location. It is not limited to a single machine, process or device.

Level 3 – Planning level/Operational management

The fourth automation pyramid level (as counted from 0) is the planning level. It employs the computer-assisted management system known as MES (Manufacturing Execution System). MES monitors the entire production process in a plant or factory, from the raw material supply to the finished product. It provides the plant management staff with a complete overview of production-related events, so that they can make informed decisions based on this data, for example, adjust orders for raw materials or freight-forwarding plans for finished products based on the actual data received from the systems.

Level 4 – Business and logistics planning

The management level is situated at the top of the pyramid. Here, the integrated ERP (Enterprise Resource Planning) system is employed, and those in charge of management can observe and control its operation. ERP encompasses various apps to connect, process and monitor everything that happens in a company. ERP uses information available at the lower pyramid levels plus additional software integrating data shared by these levels. Thanks to that, all levels of the company’s activity can be monitored, from resources to production, product distribution, purchasing, finances and payroll, etc.

Level 5 – Cloud

A “cloud” is a term that does not necessarily reflect the meaning of this area in an accurate way. The cloud is simply a cluster of devices and the apps running on them that facilitate far-reaching data collection, integration, evaluation and processing. Data can be sent to the cloud from any level of the automation pyramid. There, it can be collected, processed and evaluated by artificial intelligence software driven by machine learning mechanisms. In fact, it is the cloud and the mechanisms available there that ensure enhanced efficiency and operational excellence.

The transformation of a company to the form required by Industry 4.0 involves extensive technological and organisational modifications. It requires time and technical resources, and cannot be implemented in a short period of time. Therefore, it should be divided into stages, and specific, achievable goals, aiming for gradual change should be determined. It is also worth focusing on the local solutions before scaling up to the global ones, primarily by way of extracting the necessary information available locally and creating applications that include the use cases for such data. Bearing that in mind, the following three transformation process stages can be defined:

- Digital communication and sensors: The objective of this stage is to ensure the highest possible level of efficiency and operational excellence. Therefore, it involves productivity, quality and efficiency improvement, as well as better risk management through integration and automation, IoT solutions, artificial intelligence, cloud and advanced analytics. Its implementation involves creating a digital network and supplying it with data from a multitude of sensors. The network reliability and operation speed largely determine whether the advantages of Industry 4.0 can be fully utilised, as a “digital” company cannot operate effectively without reliable data transmission.

- Digital engineering: Its aim is to improve growth. Once the foundations have been laid, you can start looking for benefits deeper, utilising the technologies offered by Industry 4.0, with the view to improving the designing process and supply chains. In certain product groups, ”smart” products can also be developed, creating certain ecosystems in which communication and data transmission processes take place. Here, certain engineering processes can come to play, including smart automation and smart contracts based on the blockchain technology. This ecosystem can impact production processes and supply chains, ensuring further company’s operating cost optimisation.

- Digital operations: Here, the objective is to ensure a wider variety. The final stage occurs when the company is fully digital and requires utilising Industry 4.0 capabilities to obtain a truly competitive edge. Introducing the above-mentioned changes at the stages from design to the finished product will make it possible to respond quickly and efficiently to the target market needs and opinions, for instance by developing unique products. Note, however, that differentiation is not just about differentiating a company from its competitors, but also about creating entirely new markets, services and business models.

Supply is crucial during a revolution

While building a company’s automation pyramid and employing the necessary technical solutions, you will need not only routers, but also minor electronic and electromechanical components, such as indicators, sensors, connectors and many, many other elements. These will be necessary to build the network infrastructure, machine-to-machine connections, interfaces indicating the equipment status to the operator, etc. In such cases, it is worth finding a proven partner that is able to supply your business with the necessary components within a reasonably short period of time. TME is such a tried-and-tested partner. Our company’s market presence goes back to 1990, and has always been connected with product distribution and supply. The high standard of services provided has been confirmed by ISO 9001:2015-10 and ISO 14001:2015 certificates, and our product catalogue includes a diverse selection of components that are necessary to fully implement the Industry 4.0 idea.

Text prepared by Transfer Multisort Elektronik Sp. z o.o.