Factory Insights: Drawing on 25 Years of Expertise in Manufacturing Data Analysis

By: Julie Cliche-Dubois, Product Manager at Cogiscan

Going deeper than simple data visualization and dashboards, a comprehensive factory analytics platform should be defined by its capacity to delve into complex trend analysis and facilitate performance comparisons across lines and/or machines. The true value lies in its ability to identify and dissect hidden manufacturing issues, empowering users to thoroughly investigate and resolve problems at their root. While aesthetically pleasing interfaces provide a snapshot of real-time operations, the power lies in the depth of actionable insights it can offer. Meeting this analytical capability is no small feat; it requires a nuanced approach to data interpretation that goes well beyond presenting metrics, aiming instead to transform data into a strategic asset for informed decision-making and process optimization within the manufacturing landscape.

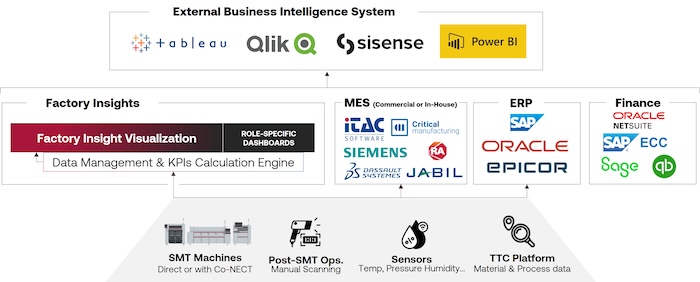

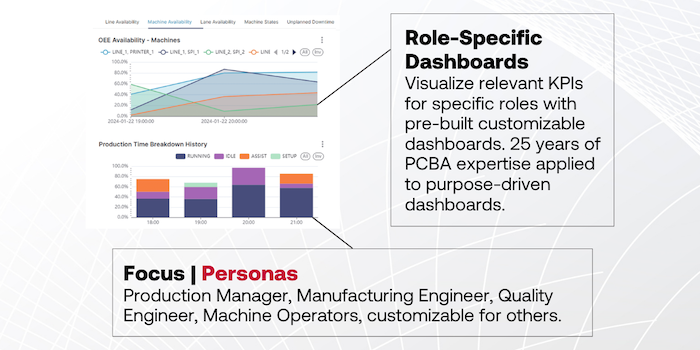

With a reputation established over the past 25 years as specialists in extracting manufacturing data, the Cogiscan team has applied this extensive expertise to a closely related domain: factory analytics – culminating in the creation of a new fully customizable analytics platform, Factory Insights. As a performance data analytics platform, Factory Insights takes data collected from the entire production ecosystem, including from machines, sensors, traceability tools (material and process information), and by leveraging a sophisticated data management engine, converts it into key performance indicators (KPIs), which are then distilled into actionable intelligence. This process enables manufacturers to make informed decisions based on comprehensive insights derived from their entire production ecosystem.

This conversion provides key performance indicators (KPIs) that are not only insightful but also actionable. With the rollout of Factory Insights, Cogiscan equips manufacturers with advanced capabilities for improving operational efficiency, accelerating workflow throughput, and diminishing waste by leveraging factory data analytics.

Differentiating Analytics from Visualizations

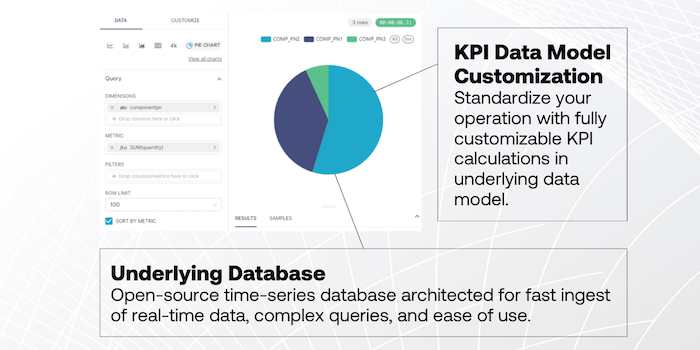

Some KPIs can be accessed directly from the machine, but many need additional contextualization to be calculated accurately. This becomes especially critical when KPIs at both the factory and production line levels are required. While most Business Intelligence (BI) platforms are adept at data visualization, they typically fall short in providing the necessary context and robust data validation, critical in the complex field of electronics and circuit board manufacturing.

As an example, we can think of Google Analytics, the most widely used analytics platform for marketing. Its superiority stems from Google's comprehensive understanding of data provenance and interpretation—after all, they are often the originator and collector of the data. Although their dashboards are impressive, it is Google Analytics' capability to intelligently decipher and present the data that truly distinguishes it from competitors.

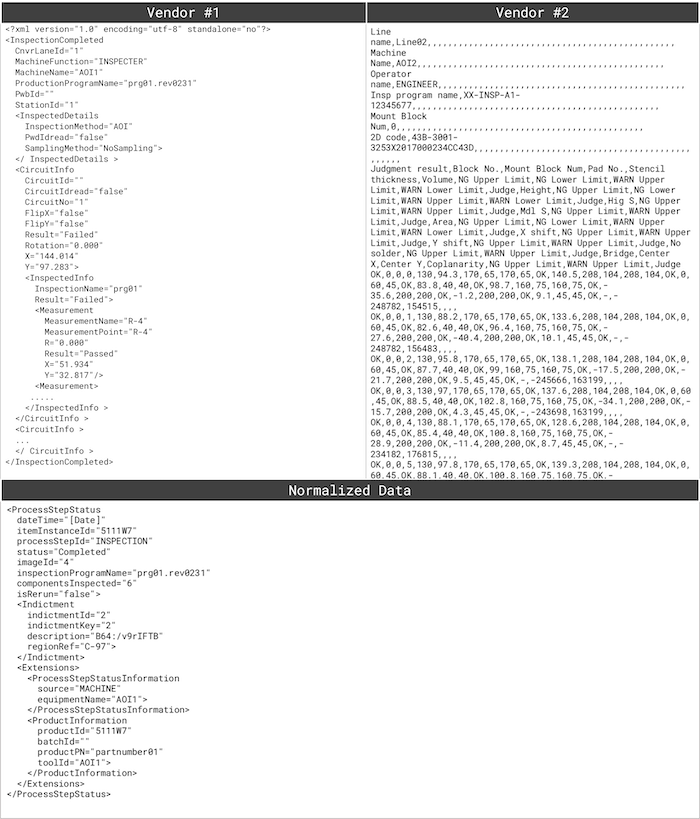

The same applies to PCBA manufacturing, where there is a deep divide between data visualization and data analytics. Cogiscan is well positioned to contextualize and enrich production data, because they’ve been connecting, accessing, processing, and sharing shopfloor data in electronics manufacturing since 1999. Solely focused on electronics manufacturing, Factory Insights includes a data enrichment & KPI calculation engine specifically designed to handle data for PCB assembly.

Factory Insights sets itself apart from competing solutions with its ability to transform structured and unstructured data from the factory floor into both coherent and actionable KPIs. From there, anything is possible: you can either use and modify Factory Insight’s pre-built dashboards, or feed the relevant KPIs to any other 3rd party analytics/BI tool, enabling a vast array of analytical possibilities.

Domain Expertise & Importance of Standardization

As noted earlier, most conventional analytics platforms fall short in grasping the intricate details specific to PCBA manufacturing, potentially leading to reports that are both undependable and ineffectual. Essentially, getting access to the data is merely the first step; the crucial aspect lies in the ability to effectively understand and utilize that data.

Detailed aspects such as double-sided PCBAs, dual lanes, recipes, and AOI re-runs all influence baseline metrics, making data standardization crucial for meaningful comparisons and informed decision-making. For instance, understanding that one line ran twice as fast as another is interesting, but without considering the context, such as if the lines were producing entirely distinct product types, this information lacks meaningful interpretation. Meaningful analysis is contingent upon an analytics platform's ability to comprehend the intricacies of the data, including the specific configurations of lines, machines, and product types.

Time-based evaluations are subject to a comparison issue. While it's beneficial to be aware that the placement machine's OEE has reached 84%, it's significantly more informative to understand the general trajectory of the machine's performance. Is 84% an outlier? Furthermore, is the trend indicating an improvement or a decline in performance? Similarly, comparing defect rates across production runs on the same line demands consistent underlying calculations; without them, the comparison lacks validity.

Put simply, the essence of any comparison lies in standardization, and achieving standardization hinges on the capability to contextualize and make sense of data under different circumstances. The adage "numbers can be manipulated to tell any story" underscores the need for KPIs to be rooted in a single, verifiable source of truth. Achieving this level of standardization and contextualization demands a rigorous approach to managing the extensive data collected from the entire manufacturing ecosystem.

The underlying engine that supports Factory Insights is engineered to handle all the intricacies of PCBA manufacturing, while supporting the option to correlate data with other 3rd party systems like MES/MOM or TTC platform.

Multi-Platform Headaches

Tools that analyze data at the machine level can offer significant insights into the unique performance and capabilities of a particular machine. However, these tools often offer a narrow viewpoint, and usually overlook the broader influence that the entire production line has on specific machine-level metrics. For instance, a low OEE reported by a the pre-reflow AOI machine on Line 2 may not be solely due to issues with the AOI itself. The root cause could lie upstream, such as a bottleneck at the placement machine, or downstream at the reflow oven.

Switching between different analytics tools, for example, moving from one machine-level analysis tool to another, can lead to difficulties with standardization and comparison, as previously described. This can result in confusion and challenges when trying to align and interpret data across different platforms. Factory Insights addresses these issues by providing a unified platform that aggregates and contextualizes data from diverse machine types. This integration allows users to evaluate holistic line OEE and drill down into the performance of a particular process, such as a specific nozzle on a placement machine.

Utilizing multiple platforms can also make root cause analyses cumbersome and manually intensive. Quality investigations demand considerable resources, and lacking insight into common causes and prioritization methods can lead to excessive time spent switching between various systems and reports. With Factory Insights, quality engineers can query consolidated data easily and create custom reports – the platform's comprehensive view includes not only real-time data but also historical data for comparative analysis. Factory Insights streamlines data analysis by consolidating it into one platform, considerably cutting down the time needed to tackle quality problems and handle warranty returns.

Factory analytics designed specifically for electronics manufacturers

In essence, factory analytics need to go beyond basic data display and dashboards, and instead offer a holistic approach that is exemplified by Cogiscan's Factory Insights. This platform does more than just show data; it strategically utilizes extensive data across the full manufacturing process to reveal trends, benchmark performance, and identify inefficiencies. Cogiscan's dedication to data handling and analysis guarantees that their customers have access to the critical insights needed to stand out and thrive in this fiercely competitive market.