PCB Pedestal technology explained

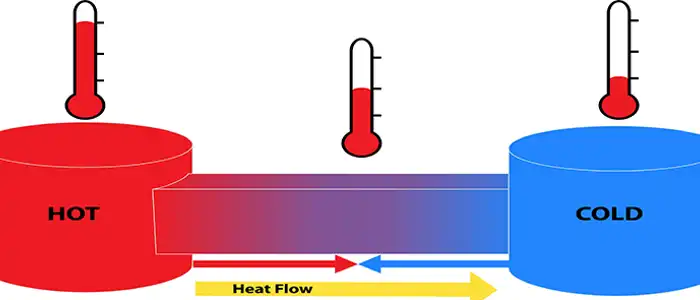

To fully understand Pedestal technology, you first need to understand that its purpose is for the Thermal Management of the PCB. Thermal Management relates to the heat output of the application and the goal is to monitor and control the heat output to prevent overheating of the electronic components which could lead to a premature failure.

As you know all electronic devices generate excess heat while they are being operated, and the components and materials which are used in these devices have individual maximum operational temperature limitations. This means that to ensure the reliability & safety of the device and its integral parts, thermal management is required.

You might ask yourself where exactly the heat in the device comes from. The answer to that is quite simple, the components mounted on the PCBs need energy to operate, and the biproduct of that is the produced thermal energy. For example, an electric current running through a copper conductor will generate heat due to the resistance of the copper. The greater the resistance of a material, the more thermal energy must be dissipated. As the temperature of the conductor increases, so does the resistance.

In order to achieve thermal management in the PCB industry, there are several cooling techniques which are used:

1. Thermal via-holes

2. IMS technology (Aluminum or Copper substrates)

3. IMS technology with micro-via-holes (IMS Copper)

4. Cu Inlays

5. Ceramic boards

6. Heat Sinks

7. Heavy copper boards

8. Pedestal technology

Now back to the question, what is Pedestal technology?

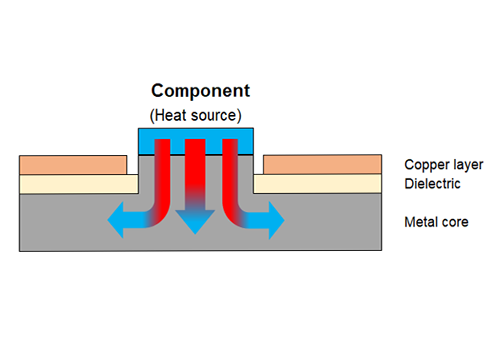

It is a very simple and effective way to dissipate heat from electronic components, due to heat source having a direct connection to the metal core. The component is placed directly on the core, and thus the thermal energy flows directly into the metal core and as a result provides optimal cooling. This technology is mainly used in applications where the thermal resistance of the parts is very low. The lower the resistance is, the better the conductivity to transfer the heat is.

This technique means you are not forced to use expensive intermediate materials which have high thermal conductivity, that transfer the heat directly to the core whereas the Pedestal Technology directly integrates the metal core and the component, which is the actual generator of the heat, and turns it into one uninterrupted thermal flow unit.

Thanks to this the heat can be transferred with less thermal resistance, and with the temperature of the component under control the product will have an extended lifetime and operating performance.

Currently, Pedestal technology is a big part of the new developments for LED applications. LEDs are highly efficient, reliable and have a longer life span which boosts the products they are utilized in. One of the latest trends in the automotive industry is the increased usage of LED technology, a component which face challenges with thermal management, so the Pedestal technology is an ideal solution. This comes at a time where stringent regulatory policies regarding conventional lighting and energy consumption across the world are expected to favor products with LED applications in the long term.

Another segment where high-power applications are experiencing a boost is in E-mobility with the chargers, converters, and power drive chains specifically.

As devices continue to get more powerful, it is inevitable that they will produce more and more heat, which makes the Pedestal technology suitable for all high-power applications. As a reference, a thermal conductivity of up to 380 W/mK can be achieved with Pedestal technology, a big difference in comparison to the standard thermal management solutions which rank up to 10 W/mK.

Manufacture of Pedestal boards.

There are 2 ways to manufacture a board which features Pedestal technology:

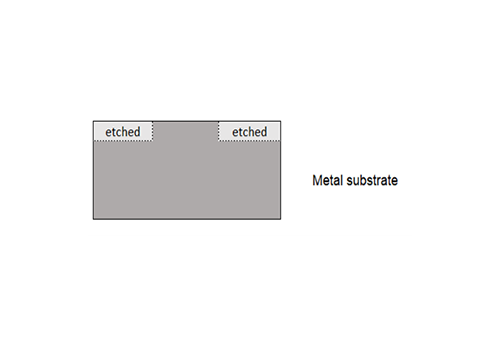

- Pedestal- by etching

In this production method, the excess material of the Metal substrate is removed by etching

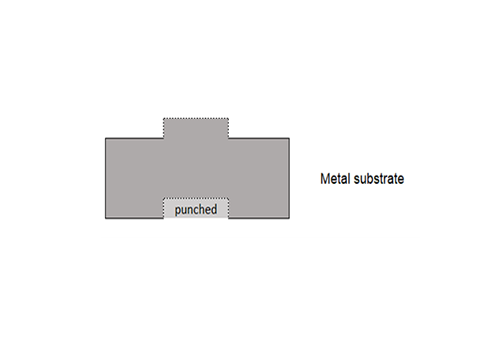

- Pedestal- by punching

In the second production method, the pedestal pad on the Metal substrate is created by punching it out from the opposite side

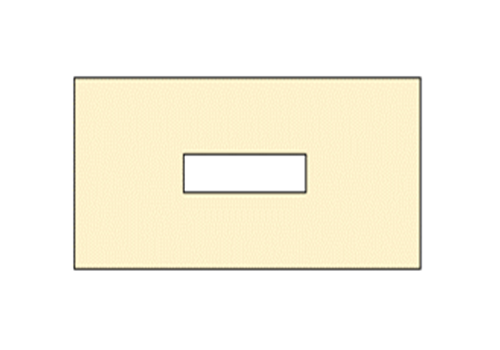

Once the Metal substrate (Copper) is ready, the next step is to pre-prepare the copper foil and the prepreg (punching, routing) to create openings in the areas where the Pedestal pads are.

- Prepreg pre-cut (routing/ punching according to the Pedestal size)

- Copper foil (routing/ punching according to the Pedestal size)

Thereafter the Dielectric (Prepreg), base material (Metal substrate) and the Copper foil need to be laminated together. Once this step is done the production process and the manufacturing steps are similar with standard Rigid and IMS boards production.

Our engineering team is available for consultation and design session for any of our PCB technologies. To get in contact please write sales@starteam.global

About Starteam CML:

Starteam CML is a global leader in the printed circuit board industry, specialized in PCB manufacturing and sustainable supply solutions for over 30 years. Our factory in Sichuan province, China, manufactures PCBs to the highest quality and reliability standards, including automotive safety requirements, supported by our Engineering & Quality experts. Starteam CML strives to deliver the most competitive premium products and supply solutions to satisfy all your PCB requirements.