Sponsored content by Viscom AG

Award-winning dual-track system S3088 DT now available

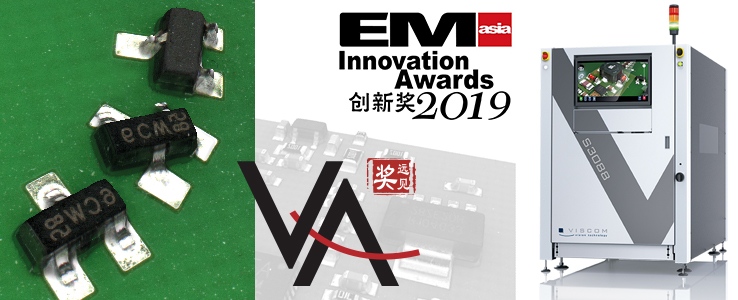

With the S3088 DT, Viscom AG has expanded its broad range of inspection systems for the electronics industry by adding an especially versatile, compact machine for dual-track operation. Following the successful launch at NEPCON China 2019, the award-winning system proved its advantages at the international trade show SMTconnect in Nuremberg, Germany, and is now ready for sale.

The S3088 DT is in its standard configuration equipped with a dual-track system for use in automatic optical inspection (3D AOI) and confidently claims both a “Vision Award” and an “EM ASIA Innovation Award” in this design. The prizes were awarded at the end of April 2019 during the NEPCON China exhibition in Shanghai.

First-class technical performance

The advantages of the S3088 DT could also be experienced at SMTconnect in May 2019. The system features a unique combination of affordability, efficiency, speed and technical performance that meets all the requirements of large-scale mass production today, including, for instance, full connection to state-of-the-art Industry 4.0 interfaces. The S3088 DT ensures reliable inspection of sophisticated 03015 components and features a very impressive throughput rate.

The system adapts to the varying track widths of relevant production jobs and also can be used in single-track operation. Another key feature of the S3088 DT is its ability to inspect even the largest printed circuit boards.

New design for smallest footprint

Compared to the 3D AOI system S6056, the S3088 DT is considerably more compact, particularly with regard to its width. Moreover, the monitor features a fold-out keyboard integrated in the door of the machine housing to save even more space – a new solution that Viscom introduces with this system. The design of the award-winning S3088 DT therefore shows off its advantages particularly when space is tight in production.

Many configurations to choose from

With regard to its sensor technology, the S3088 DT provides outstanding flexibility: in addition to its configuration for the most sophisticated 3D AOI tasks, configurations for solder paste inspection (3D SPI), conformal coating inspection (CCI) and underfill inspection (UFI) also are available.

For more information click here

.jpg)