© farang dreamstime.com

Application Notes |

Improving Current Sense and System Efficiency in Industrial Motion Control

Industrial motion control covers a breadth of applications, ranging from inverter based fan or pump control, to factory automation with more complex AC drive control, to advanced automation applications such as robotics with sophisticated servo control.

These systems require sensing and feedback of a number of variables such as motor winding current or voltage, DC link current or voltage, rotor position and speed. The selection of variables and the required measurement precision depends on the end application demands, the system architecture, target system cost, or system complexity amongst other considerations such as value-add features e.g. condition monitoring. With motors reportedly consuming 40% of worldwide energy, international regulations have increased the focus on system efficiency across the entire range of Industrial motion applications increasing the importance of these variables, especially current and voltage.

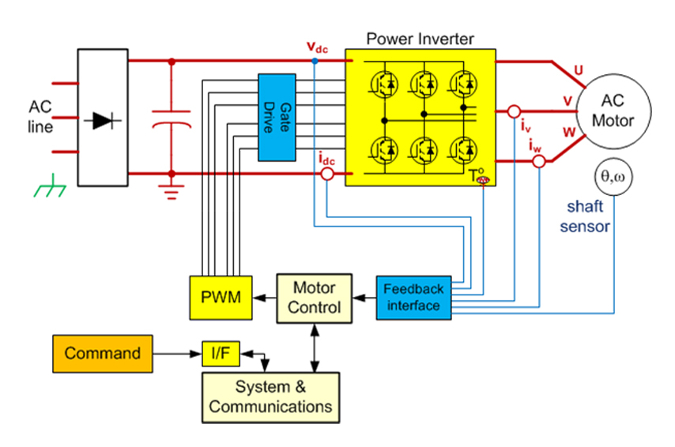

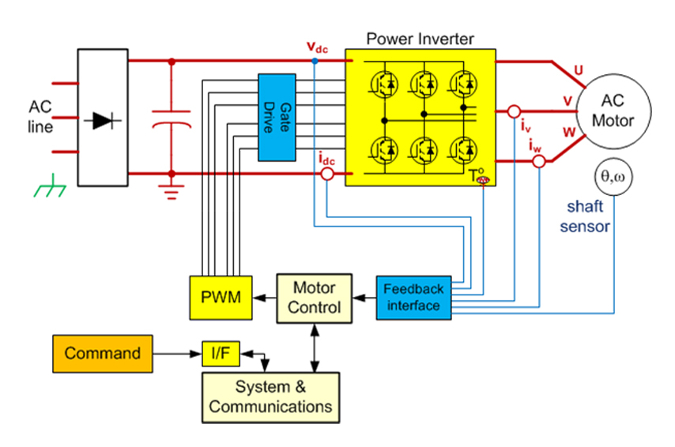

A generic motor control signal chain is shown in 1. Signal conditioning to realise a high fidelity measurement is not trivial. Phase current sensing is particularly challenging, as this node is connected to the same circuit node as the gate driver output within the heart of the power stage (inverter block) and therefore experiences the same demands in terms of isolation voltages and switching transients.

Figure 1. Generic Motor Control Signal Chain

The most commonly used current sensors in motor control are shunt resistors, Hall effect (HE) sensors and current transformers (CT). While shunt resistors don’t provide isolation and incur losses at higher currents they are the most linear of all the sensors, the lowest cost and suitable for both AC and DC measurements. The signal level reductions needed to limit shunt power losses typically limit shunt applications to 50A or less.

CTs and HE sensors provide inherent isolation allowing them to serve high current systems, but they are higher cost and result in a less accurate solution than that which can be achieved through shunt resistor usage, either due to the sensor itself having poorer initial accuracy or worse accuracy over temperature. While there are several motor current measurement nodes to choose from as shown in 2, direct in phase winding current measurement is the ideal and used in the highest performance systems. A key objective for most system designers is to improve the current sense feedback in order to improve efficiency within their cost targets.

Figure 1. Generic Motor Control Signal Chain

The most commonly used current sensors in motor control are shunt resistors, Hall effect (HE) sensors and current transformers (CT). While shunt resistors don’t provide isolation and incur losses at higher currents they are the most linear of all the sensors, the lowest cost and suitable for both AC and DC measurements. The signal level reductions needed to limit shunt power losses typically limit shunt applications to 50A or less.

CTs and HE sensors provide inherent isolation allowing them to serve high current systems, but they are higher cost and result in a less accurate solution than that which can be achieved through shunt resistor usage, either due to the sensor itself having poorer initial accuracy or worse accuracy over temperature. While there are several motor current measurement nodes to choose from as shown in 2, direct in phase winding current measurement is the ideal and used in the highest performance systems. A key objective for most system designers is to improve the current sense feedback in order to improve efficiency within their cost targets.

Figure 1. Generic Motor Control Signal Chain

The most commonly used current sensors in motor control are shunt resistors, Hall effect (HE) sensors and current transformers (CT). While shunt resistors don’t provide isolation and incur losses at higher currents they are the most linear of all the sensors, the lowest cost and suitable for both AC and DC measurements. The signal level reductions needed to limit shunt power losses typically limit shunt applications to 50A or less.

CTs and HE sensors provide inherent isolation allowing them to serve high current systems, but they are higher cost and result in a less accurate solution than that which can be achieved through shunt resistor usage, either due to the sensor itself having poorer initial accuracy or worse accuracy over temperature. While there are several motor current measurement nodes to choose from as shown in 2, direct in phase winding current measurement is the ideal and used in the highest performance systems. A key objective for most system designers is to improve the current sense feedback in order to improve efficiency within their cost targets.

Figure 1. Generic Motor Control Signal Chain

The most commonly used current sensors in motor control are shunt resistors, Hall effect (HE) sensors and current transformers (CT). While shunt resistors don’t provide isolation and incur losses at higher currents they are the most linear of all the sensors, the lowest cost and suitable for both AC and DC measurements. The signal level reductions needed to limit shunt power losses typically limit shunt applications to 50A or less.

CTs and HE sensors provide inherent isolation allowing them to serve high current systems, but they are higher cost and result in a less accurate solution than that which can be achieved through shunt resistor usage, either due to the sensor itself having poorer initial accuracy or worse accuracy over temperature. While there are several motor current measurement nodes to choose from as shown in 2, direct in phase winding current measurement is the ideal and used in the highest performance systems. A key objective for most system designers is to improve the current sense feedback in order to improve efficiency within their cost targets.

Migration from HE Sensors to Shunt Resistors Shunt resistors coupled with isolated sigma-delta modulators provide the highest quality current feedback, (where the current level is low enough for shunt usage). There is a significant trend for system designers to migrate from HE sensors to shunt resistors, with an additional trend to move to the isolated modulator approach versus an isolated amplifier approach. The AD7401A isolated sigma-delta modulator based on Analog Devices, Inc., iCoupler® technology has been an ideal product choice in the uptake of this trend with a differential input range of ±250 mV ideally suited to resistive shunt measurements. The original information can be reconstructed from the single bit digital output (up to 20MHz) with an appropriate digital filter, commonly a Sinc3 filter for precision current measurements. As conversion performance can be traded off versus bandwidth, or filter group delay, a coarser, faster filter can provide fast response over current protection in the order of 2µs, ideally suited to IGBT protection, potentially eliminating associated analog circuitry. From a signal measurement aspect, there are some key challenges associated with the shunt resistor selection as there is a trade-off between sensitivity and power dissipation. There is a strong demand to reduce shunt resistor sizes to minimize losses and self-heating effects and a common need to select a shunt size that will service many models and motors at different current levels. Maintaining dynamic range is also challenging in the face of peak currents that can be several times the rated current of the motor and the need to reliably capture both. Industry’s Highest Performance Isolated Sigma-delta Modulator It is evident that a higher performance Isolated Sigma-delta modulator would support several needs and trends within industrial motor control designs and improve the power efficiency of motor drives through shunt resistor size reduction; improved sensorless control schemes; enabling the control of high efficiency interior permanent magnet motors (IPM). The AD7403 from Analog Devices is the next generation product to the AD7401A, providing much wider dynamic range at the same external clock rate of 20MHz. This allows more flexible shunt size selection, optimising drive to motor matching, improving nominal and peak current measurement, reducing the impact of a single shunt size for a range of motor models and allowing for shunt resistor usage in place of HE sensors at higher current levels. Dynamic response can also be improved through reduced measurement latency. The AD7403 also features an isolation scheme with a higher continuous working voltage (VIORM) than the previous generation AD7400/01A, which can also contribute to higher system efficiency through the use of higher DC bus voltages and thus lower motor currents. Broader System Solution Including the ADSP-CM40x Mixed Signal Control Processor Digital filtering is traditionally implemented with an FPGA or digital ASIC and considered expensive. The advent of the ADSP-CM408F Mixed-Signal Control Processor which includes hardware Sinc3 filters, to which the AD740x series of isolated sigma-delta modulators can directly connect, is likely to lead to an increased rate of adoption of the resistive shunt current sensing technique coupled with isolated sigma-delta modulators. The ADSP-CM408F is a cost effective solution and should enable many designers to consider resistive shunt current sensing who were previously constrained by their cost targets and therefore allow them to achieve higher system efficiency. ----- author: Nicola O’Byrne, senior system applications engineer with the Motor and Power Control team (MPC) within the Industrial and Instrumentation segment in © Analog DevicesFigure 2. Isolated and non-Isolated Motor Current Feedback / image with zoom