Space Forge Inc., United Semiconductors advance in-space chipmaking

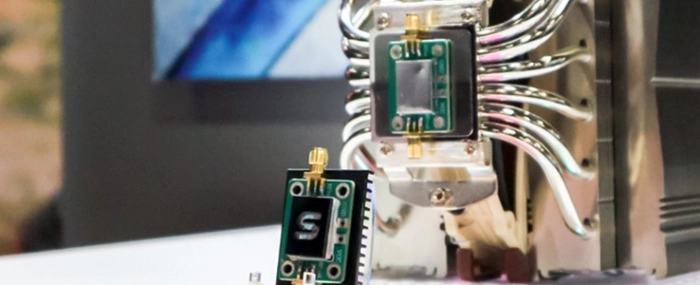

The partnership establishes a collaborative foundation for developing commercially viable in-space semiconductor manufacturing capabilities, combining Space Forge Inc.’s microgravity-enabled materials deposition processes with United Semiconductors’ expertise in ternary III-V semiconductor crystal growth and wafer processing.

Florida-based Space Forge Inc. has signed a Memorandum of Understanding (MoU) with United Semiconductors, a specialist in bulk crystal growth of III-V semiconductor compounds, formalizing the ongoing collaborative efforts that started over a year ago.

The partnership establishes a collaborative foundation for developing commercially viable in-space semiconductor manufacturing capabilities, combining Space Forge Inc.’s microgravity-enabled materials deposition processes with United Semiconductors’ expertise in ternary III-V semiconductor crystal growth and wafer processing, according to a media release.

Under the MoU framework, Space Forge Inc. will design and develop advanced materials deposition processes and equipment, and integrate manufacturing systems compatible with its ForgeStar platform.

United Semiconductors, which is based in California, will contribute its crystal growth processes, design specialized equipment and accessories for in-space manufacturing environments, identify potential materials suitable for space-based production and perform comprehensive wafer processing and testing. Leveraging their combined complementary capabilities, the partnership will bring joint projects to rapid fruition for end customers’ needs, the media release said.

“This partnership marks an exciting evolution in our mission to establish a robust US semiconductor manufacturing footprint that onshores reliable and resilient supply chains here at home,” said Space Forge Inc. President Michelle Flemming. “By combining our terrestrial and microgravity manufacturing capabilities with United Semiconductors’ deep expertise in crystal growth and wafer processing, we’re creating a powerful collaboration that can demonstrate the commercial viability of space-based semiconductor production.”

“This partnership brings together key technical expertise that is essential for the rapid development of semiconductor materials manufacturing in space and its potential for commercialization for next generation terrestrial and space microelectronics,” said Dr. Geeta Rajagopalan, President and CEO, United Semiconductors. “A robust commercial space economy in low-Earth orbit (LEO) will stimulate sustainable non-NASA utilization of future commercial LEO destinations (CLDs) and orbital platforms, assisting the US domestic industry to gain and/or maintain leadership in many critical technology sectors.”

.jpg)