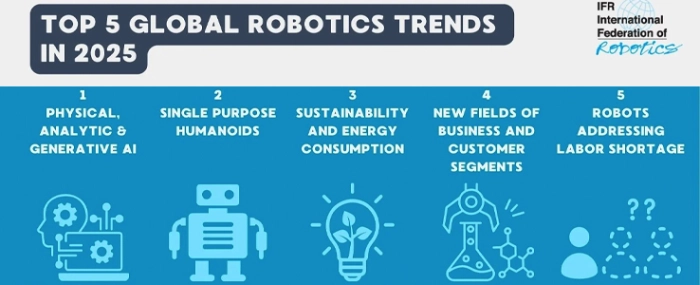

Top five global robotics trends for 2025

The global market value of industrial robot installations has reached an all-time high of USD 16.5 billion. The industry’s growth is set to accelerate, fueled by technology innovations, shifting market dynamics, and emerging business opportunities. Looking ahead to 2025, the International Federation of Robotics highlights five key trends shaping the future of robotics.

1 – Artificial Intelligence – physical, analytical, generative

Artificial intelligence is driving significant advancements in robotics. Analytical AI enables robots to process large amounts of sensor data, allowing them to adapt to unpredictable environments and optimise their performance in tasks such as high-mix, low-volume production or public operations. Physical AI takes this further by letting robots train in virtual environments, learning from simulated experiences rather than relying solely on programming. Meanwhile, generative AI projects aim to create groundbreaking advancements, akin to a “ChatGPT moment,” for Physical AI. This AI-driven robotics simulation technology will advance in traditional industrial environments as well as in service robotics applications.

2 – Humanoids

Humanoid robots, designed to mimic human form and functionality, are gaining media attention. Startups envision them as versatile tools for tasks like loading dishwashers or working assembly lines. While industrial manufacturers currently focus on single-purpose humanoids for specific tasks in automotive and warehousing sectors, broader applications could emerge in logistics and other fields where the humanoid form provides inherent advantages. Despite challenges in achieving economic scalability, the potential for humanoid robots in practical applications continues to grow.

3 – Sustainability – energy efficiency

Robots are becoming essential to achieving sustainability goals. Their precision reduces material waste, ensures consistent product quality, and supports the production of green technologies like solar panels and EV batteries. Additionally, advancements in energy-efficient robot designs — such as lightweight components, energy-saving modes, and bionic grippers — help minimise their own environmental footprint. As manufacturers face increasing pressure to comply with global sustainability regulations, robots are emerging as critical tools for eco-friendly and cost-effective production.

4 – Robots - new fields of business

The general manufacturing industry still has a lot of potential for robotic automation. Most manufacturing companies are small and medium-sized enterprises (SMEs). The adoption of industrial robots by SMEs is still hampered by high initial investment and total cost of ownership. Robot-as-a-Service (RaaS) business models allow enterprises to benefit from robotic automation with no fixed capital involved. RaaS providers specialising in specific industries or applications can offer sophisticated solutions quickly. In addition, low-cost robotics offers solutions for potential customers that find a high-performance robot to be oversized for their needs. Many applications have low requirements in terms of precision, payload, and service life. Low-cost robotics addresses this new “good enough” segment.

Interesting new customer segments beyond manufacturing include construction, laboratory automation and warehousing. Demand across all industries is being driven by the fact that recent crises have led to political awareness of domestic production capacity in strategically important branches. Automation allows manufacturers to nearshore production without sacrificing cost efficiency.

5 – Robots addressing labour shortage

Global labour shortages, exacerbated by demographic shifts in major economies, continue to challenge industries, according to the International Labour Organisation (ILO). Robots are increasingly being used to fill these gaps by automating repetitive, hazardous, or physically demanding tasks, such as heavy lifting, quality inspection, or painting. Collaborative robots and mobile manipulators make deployment more flexible, allowing companies to adapt quickly to workforce shortages. By taking over tedious jobs, robots free up human workers to focus on more engaging and higher-value roles, helping businesses maintain productivity despite ongoing labour challenges.