Laser Photonics advances PCB marking technology R&D

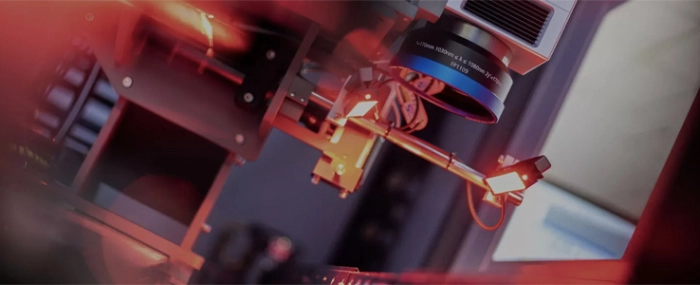

Industrial laser systems developer Laser Photonics Corporation, and its recently acquired subsidiary Control Micro Systems (CMS), are expanding their PCB Marking technology development program targeting the semiconductor and electronics market.

Laser marking is crucial for semiconductor production, a market projected to hit USD 1 trillion annually by 2030. High-speed laser processing equipment is key to meet the growing demand for advanced chips. CMS develops automated PCB Marking technology providing a high-speed process for etching serial numbers, barcodes, logos, and other tracking data with precision and efficiency. These systems can be configured for standalone operation or integrated into existing SMT lines.

“Combining CMS’s expertise with our R&D initiatives allows us to further develop its cutting-edge PCB Marking Technology to meet the semiconductor sector’s stringent demands,” says Wayne Tupuola, CEO of LPC, in a press release. “We are excited to continue pushing the boundaries of what is possible with laser technology as we work toward setting new industry standards.”

The current PCB Marking systems built by CMS are Class I systems that can effectively mark onto all types of PCB, including FR-4, CEM-1, phenolic paper, ceramic substrates, and solder mask substrates. These laser marking systems use off-axis machine vision to detect fiducials, determine processing locations, and verify marked data. CMS Laser is a certified Cognex integrator, leveraging expertise with advanced camera systems.

For LPC, as a provider of industrial laser equipment, semiconductor technologies are a new sector of focus. Supplemented by CMS expertise, LPC will dedicate resources to research and development in this sector in accordance with its diversification strategy.