Thin-film electronics can be 'fabbed', say researchers

New research by KU Leuven and imec concludes that the foundry production model can be applied to the field of flexible thin-film electronics.

In the current century the mass production of conventional silicon chips has been transformed by the fabrication (fab) model, which separates the design of processors from their manufacture.

This has resulted in an explosion of innovation and technical advancement. However, the 'sister' industry of thin-film transistors (TFTs) has not enjoyed the same upwards curve. TFTs enable promising applications such as wearable healthcare patches and robotic interfaces, but limits on the method of production have held back the space.

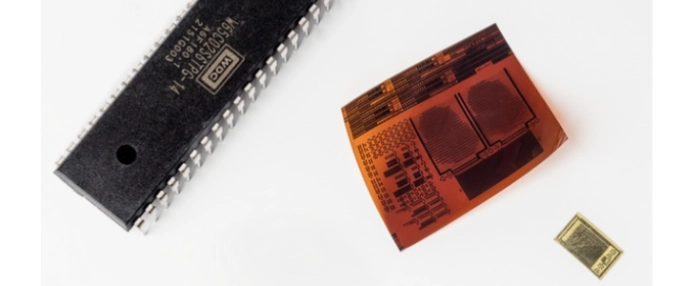

Now, researchers at KU Leuven and imec believe they have proved that the foundry business model is also viable in the field of thin-film electronics. They designed a specific TFT-based microprocessor and sent it for production in two foundries, after which they tested it in their lab, with success.

The same chip was produced in two versions, based on two separate TFT technologies (using different substrates) that are both mainstream. In both cases the chips were manufactured on the substrate together with other chips, or ‘projects’. This ‘multi-project’ approach enables foundries to produce different chips on-demand from designers on single substrates.

“This field can benefit hugely from a foundry business model similar to that of the conventional chip industry”, says Kris Myny, professor at the KU Leuven’s Emerging technologies, Systems and Security unit.