Singaporean researchers develop ultra-thin wearable chips

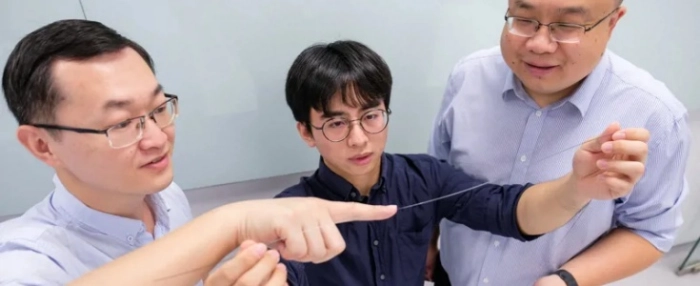

A team at Nanyang Technological University, Singapore (NTU Singapore) has successfully fabricated a hair-thin semiconducting fibre that can be woven into fabrics to create wearable electronics.

The researchers say the material can support traditional manufacturing methods to make flexible electronics without defects for stable signal transmission. Usually, these processes cause cracks and deformities in the semiconductor cores.

The NTU team overcame the problem by selecting pairs of common semiconductor material and synthetic material – a silicon semiconductor core with a silica glass tube and a germanium core with an aluminosilicate glass tube. The materials were selected due to their qualities of thermal stability and electrical conductivity.

In a statement, NTU Associate Professor and lead principal-investigator, Wei Lei, said: “Semiconductor fibre fabrication is a highly complex process, requiring know-how from materials science, mechanical, and electrical engineering experts at different stages of the study. The collaborative team effort allowed us a clear understanding of the mechanisms involved, which ultimately helped us unlock the door to defect-free threads, overcoming a long-standing challenge in fibre technology.”

When subjected to responsivity tests, the fibres could detect the entire visible light range, from ultraviolet to infrared, and transmit signals of up to 350kHz bandwidth. The fibres were 30 times tougher than regular ones and multiple machine washes did not impede performance.

To demonstrate the tech, the research team developed a smart beanie hat to help a visually impaired person cross the road safely and a shirt that transmits data through an earpiece.