Orbit One upgrades Swedish unit with new robot cell

EMS provider Orbit One has upgraded the production unit in Ronneby, Sweden with the installation of a new robot cell.

The cell has, according to the EMS provider, been specially designed on behalf of a large Swedish industrial company in order to manufacture identification and traceability solutions with built-in analytical tools.

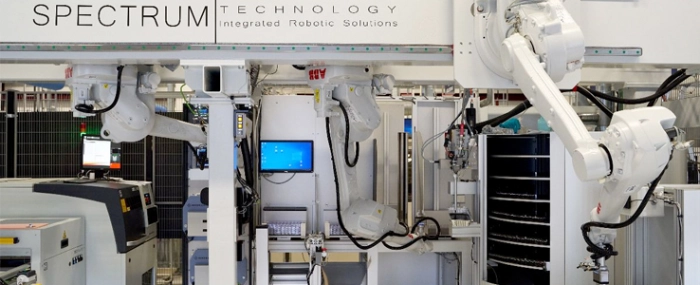

”We received an inquiry on whether we could design an effective and sustainable solution for their manufacturing. Thanks to our fantastic cooperation with the customer and the automation consultants Spectrum Technology, we have now built a unique solution, which is fully operational,” says Vice President & Chief Operating Officer, Ulf Karlsson from Orbit One, in a press release.

Mr. Karlsson continues to explain that the new robot cell is complex, but still unbelievably space-efficient. It is fitted with three robotic arms but still only requires one operator.

”The cell manufactures the entire unit and the robot handles all steps from depanelisation with laser, laser soldering, printed circuit board testing, battery assembly for plastic encapsulation and laser marking of the finished product. The quality requirements are extremely high and casting is done with the maximum possible accuracy. The robot cell configuration delivers one product every 30 seconds,” says the COO.

The cell has, and will continue to, strengthen and improved Orbit Ones competence and competitiveness, according to Mr. Karlsson.

”It is also gratifying that with this deal we show that we can compete with low-cost countries like China, for example, thanks to our high technical expertise. Manufacturing is also brought closer to the customer, which is of utmost importance during the development of complex products, when close collaboration is essential for the final result,” Ulf Karlsson concludes.