Scottish graphene firm invests to scale up manufacturing

Integrated Graphene has announced plans to invest up to £8 million in scaling up its 3D Graphene foam manufacturing process to meet surging global demand from the human diagnostics and energy markets.

The company says it has developed the world’s "only commercially viable graphene manufacturing process that is currently scaled to high volumes", a press release reads.

This novel process, the company further states, eliminates the scale-up challenges associated with CVD graphene and graphene powder. As well as direct manufacturing, Integrated Graphene is designing manufacturing processes for blue-chip companies to bolt-on to existing lines.

The company’s investment plan will focus on scaling-up the manufacturing of its market-ready graphene enhanced electrodes and super capacitors which are currently being piloted by global blue-chips in human diagnostics point of care testing and smart label asset tracking applications.

As part of its growth plans, the company intends to double its existing footprint in Stirling and treble its headcount to 100 over the next three years, hiring a significant number of market leading development and commercial experts in the UK, Europe and North America.

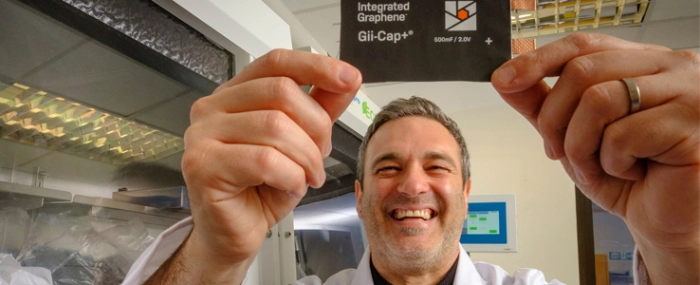

The company will also increase capital expenditure in its next generation pilot line to allow rapid market expansion of Gii-Sens and Gii-Cap. For Gii-Sens, that includes wearables, animal diagnostics, companion diagnostics, environmental diagnostics. With Gii-Cap, expansion markets include Drones, e-mobility, space, satellites, and wearables.

This investment marks a real tipping point for Integrated Graphene and the manufacturing of our unique 3D Graphene foam in its first two market-ready products, Claus Marquordt, CEO at Integrated Graphene, said in the press release.