Scanfil improves prototyping capabilities at Malmö factory

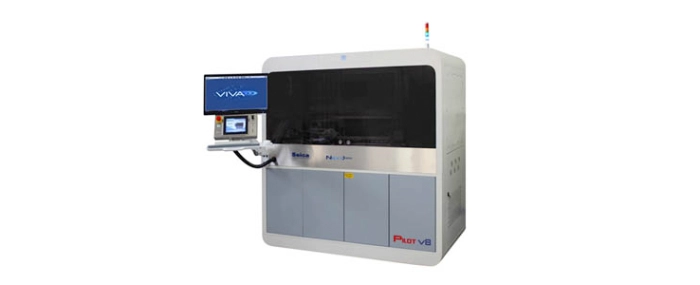

In April, just a month away, Malmö will become the fourth Scanfil factory to adopt Seica's V8 automated testing system.

The new flying probe replaces an old Takaya system and significantly improves the Swedish factory's capabilities in prototyping and new product introduction (NPI), a press release from the EMS provider reads.

The selected Seica flying probe machine is a testing device which is described as "perfect" for Scanfil’s high mix – low volume production environment.

“The new Seica V8 flying probe is easier to use, more accurate, and programmable than previous Takaya. It reduces time-to-market significantly compared to the previous system we had. Seica is ideal for Scanfil high mix – low volume production”, says Carl-Johan Forsberg, the managing director of Scanfil Malmö, in the press release. “The new flying probe increases our capabilities significantly at Malmö and provides a low threshold testing solution for prototype and low volume manufacturing that complements our fixture based ICT and FCT solutions very well.”

After Malmö, the EMS provider's factory in Pärnu, Estonia will be the next factory to invest in Seica V8 flying probes. After that, all electronics focused factories are covered.

“Seica fulfilled our needs perfectly and is directly compatible with our Siemens’ MES and Valor process preparation solution. Due to this, it enables us to provide prompt feedback to the design team and allow them to make fast changes in the design,” says Riku Hynninen, the Chief Development Officer of Scanfil. “The unification and increase in capabilities are keys to success at Scanfil. We aim to have unified and state-of-art platforms across our production infrastructure, which creates flexibility in production between sites and also cost benefits”.