© ROEQ

General |

A Danish company with a ‘Lego’ approach to robotics

It shouldn’t come as a surprise that a company with an approach like the one of ROEQ hails from Denmark, and even less that it’s situated right in the middle of the island of Funen, a major European hub for robotics.

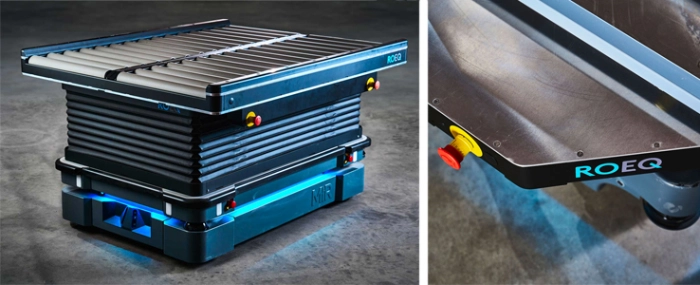

ROEQ (short for Robotic Equipment) develops equipment for mobile robots, add-ons and modules that aims to make the robot more versatile in its usability. The goal with the solutions is to bridge the gap between the warehouse and production which then would allow for fully automated internal logistics between storage and production.

The company is a fairly young company, established in 2017, and has already managed to launch several products on the market. All these products are add-ons and modules for already existing and well established mobile robots. And in September the company released six new products taking aim to solve issues such as safety, lifting and moving materials with top roller mounted on mobile robots.

The new products take aim at building upon autonomous mobile robots from MiR and consists of the GuardCom System, consisting of the GuardCom and the GuardCom Connect, a new lifter and four new top roller modules. The question is, where does the idea to develop equipment for established robotics solutions come from? Evertiq reached out to ROEQ co-founder and managing director, Michael E. Hansen, to find out where the seed was planted “The idea of developing top modules for MiR AMRs begun when my consulting firm, Produkt Innovation did some consulting work for MiR. This idea was further enhanced when I moved on to work for MiR between 2017 – 2019 as a hardware manager in their R&D department. I saw the gap in the market between having the new technologies to actual adoptions by businesses. This is where standard and ready to implement mobile robotic equipment will bring great business benefits to businesses and integrators as it lowers the barriers to accessing new technologies and enables the development and implementation of complete and high performing MiR AMR solution at ease and within a shorter time,” Mr. Hansen explains. As stated earlier, the company is young, quite young for having so many products available on the market. But its a matter of prioritising, which becomes obvious when Hansen says that “Our team of developers makes up about 70% of our staff strength.” And taking the idea from blueprint to a market ready product took about a year according to the managing director; and for the second generation, that time frame is set to become shorter. As a developer of accessories for mobile robots, the general objective is to reduce the need for human interaction/intervention where a mobile robot is deployed, but how much time and energy is actually saved with the usage these solutions? “Our vision is really to facilitate a factory environment where our robotic equipment and AMRs work in tandem with people. We are focusing on areas where the process would have stayed idle as an operator may not be present at all times to tend to only that process. As such, we focus a lot on optimising production processes, improving productivity, reducing downtime and relieving human operators from non-ergonomic work tasks,” Mr. Hansen says. He continues to explain that another vision the company has is to lower the barriers of businesses accessing new technologies and allowing integrators to turnaround projects quicker. Looking back at the events of the current year, with the current ongoing pandemic, the push for true industry 4.0 seems to be gaining speed. Having full blackout factories or factories with as few people within them as possible might still be some years away, but it seems as if the industry is moving towards less and less human intervention within their lines – how would you say that the pandemic has affected the business of ROEQ, or rather the business opportunities for ROEQ? “For ROEQ, the focus is to support collaborative robotic adoptions. Industry 4.0 concept may be gaining speed but we are also seeing the industry 5.0 advocation which we see more to coincide with our vision. We believe some tasks are best for machines to handle and some are best for people to handle. As such, businesses should find the best possible ways for machines and humans to work in tandem,” says the managing director. In regards to how the current pandemic has affected the business operations of the company Mr. Hansen says that they have definitely seen the impact the pandemic has had on the manufacturing sector. “ROEQ is not growing as it had projected in the beginning of this year but we are still experiencing a close to 3 digit growth year to date,” Mr. Hansen says and concludes with a projection of what he believes is to come. “The onset the pandemic has certainly made businesses rethink the way they are producing and we believe that we will see an increase in adoptions of collaborative robotic solutions, especially in collaboration with plug and play, safe and reliable products where there is equal share of work tasks in the factories and where people may not necessarily work in close proximity or even be physically present. The workforce will be upskilled to program, operate and control machines; possibly remotely in most cases.”Michael E. Hansen © ROEQ