© Trackwise Designs

PCB |

New deal with UK EV manufacturer enables Trackwise to scale up flex PCB production

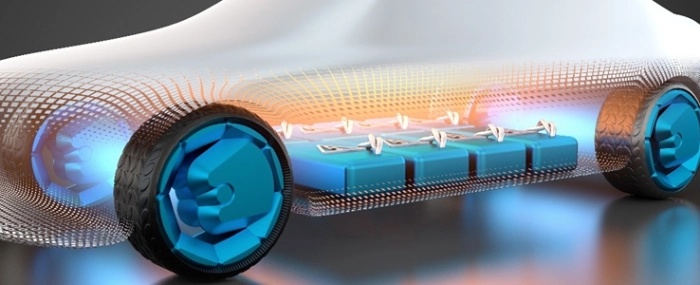

Trackwise Designs has signed a three-year agreement to manufacture and supply flexible printed circuit (FPC) boards to a UK manufacturer of electric vehicle (EVs). The agreement has the potential to be worth up to GBP 38 million over the period.

The large quantity and precisely defined cell connections and monitoring locations in battery modules are well-suited to FPCs. Using FPCs in EVs saves part count and assembly time. They also save space and weight in the final product, enabling the vehicle to go further on a single charge and reducing vehicle emissions. The FPCs will be produced using Trackwise’ patented Improved Harness Technology (IHT), which can then be made to any length depending on requirements; meaning that manufacturers are no longer restricted to traditional, shorter lengths.

The UK government has ambitions for domestic companies to be at the global forefront of ultra-low emission vehicle (ULEV) development, manufacture and use. In 2017, their Industrial Strategy included an investment of GBP 274 million into the Faraday Battery Challenge to develop, design and manufacture world-leading batteries in the UK.

“The UK was the first major economy to set a legally binding target to cut its greenhouse gas emissions to “net-zero” by 2050. We’re delighted to be working with a UK-based EV manufacturer at the forefront of driving the adoption of sustainable technologies and we acknowledge and are grateful to the support of the Faraday Battery Challenge. The selection of Trackwise to help power EVs at scale is a fantastic endorsement of how our technology can help the UK build a robust and reliable domestic supply chain. This in turn will help the government achieve its goal in significantly reducing CO₂ emissions,” says Philip Johnston, CEO of Trackwise, in a press release.