© Gemosz

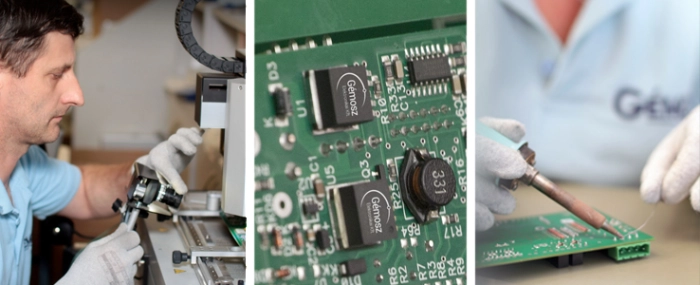

Electronics Production |

Gémosz is still looking to grow – but the pandemic brought new perspectives

Winston Churchill famously said, “Never let a good crisis go to waste”. While this was said in a vastly different context than the current crisis of the COVID-19 pandemic, there is still truth to the fact that a crisis not only allows for change – but sometimes forces it.

Change was – and still is – required; but instead of panic and haste, the Hungarian EMS provider Gémosz Elektronikai Kft. has been devoting these strange times to rethink their strategy and move towards modernisation.

Historically speaking, all various industrial revolutions have been connected with the invention of the steam engine, the development of military technology or the spread of electronics. Now, the question is – will the current pandemic have the power to induce changes to the trends of the current industry 4.0 revolution? That is the question that the Hungarian EMS provider is currently asking itself. And in general, the company does acknowledge that the opinion once held has changed during the pandemic, especially in regards to locations, tools, workflows and infrastructure – and this just over a matter of days.

“Both as an individual and as a company head my duty is to use this time for improvements in terms of automated work, processes, digital trust, infrastructures at the company and also at home, risk management and so on,” explains Barnabas Nagy, plant manager and commercial director of Gémosz.

With transparency in mind Gémosz carried out organssational changes, clarified tasks and responsibilities. They provided their employees with opportunity for home with the aid of remote communication and e-learning thru investing in IT tools and softwares. A good example if that this actually does work rather well, was an American customer sales and manufacturing contract which was finalised with e-signature.

“Nevertheless, I consider the decision and introduction of a new ERP to be the greatest achievement during pandemic. This really illustrates it well, the fact that physical contact is not absolutely necessary for developments that requires continuous interaction even with an external company,” says Mr Nagy.

The company is expecting to launch this in early August 2020, which would mean a start to the end of a seven month long duration.

Additionally in these days the reconstruction of the company’s facility in Vác is still going on. “The goal is to expand the final assembly (box-built) capacity by 50% and create the opportunity to place further SMT lines to satisfy the increased customer demand,” Mr. Nagy tells Evertiq.