© Nano dimension

Electronics Production |

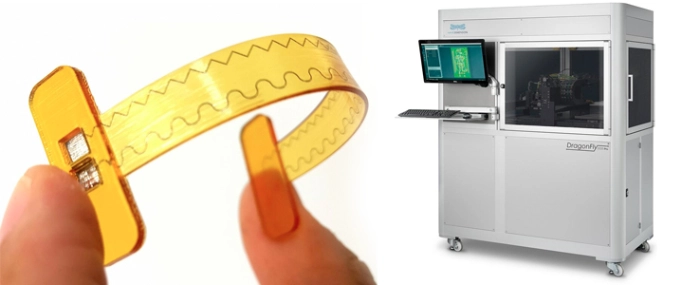

IIT prints 3D embedded sensors using Nano Dimension system

The Center for Biomolecular Nanotechnologies (CBN) of the Istituto Italiano di Tecnologia (IIT), is using Nano DImension's DragonFly additive manufacturing system to 3D print embedded sensors in electrical packaging.

IIT is a research institute in Italy with the mission of promoting technological development and higher education in science and technology. IIT plans to use the electrical packaging for rapid device and microsystem prototyping of next generation micro-electro-mechanical systems (MEMS) and wearable transducers for information and communication technology (ICT) and biomedical applications.

IIT researchers will utilise their expertise in MEMS to develop reliable real time monitoring and energy harvesters for long battery life or battery-free operation of devices.

“One of the main breakthroughs achieved by the researchers was the procedure of embedding the sensors into the interior layers of the packaging, typically a complex, multi-stage process,” said Amit Dror, CEO of Nano Dimension. “3D printing embedded sensors within electrical packaging avoids injection molding processes, reduces the need for human touch in assembly steps compared to traditional methods and eliminates wires, soldering and connectors. Placing the sensors into the interior layers of the package can also free up space, to make the structure smaller, lighter and less expensive to produce.”

Embedding the sensors was achieved by exploiting the DragonFly’s precise multi-material inkjet deposition system that allows for simultaneous 3D printing of conductive silver nanoparticle ink (metal) and insulating ink (dielectric) via a layer-by-layer fabrication process. Printing was paused in order to place the sensor on pre-printed recesses and continued to complete the job and seal the sensor.

“The suitability of the DragonFly system to rapidly and affordably manufacture functional prototypes, combined with the broad ecosystem of applications for health and energy harvesting, makes it an ideal choice for our team to achieve higher performance, quick development and print complex shapes not achievable using traditional manufacturing processes,” said Prof. Massimo De Vittorio (CBN-IIT – Lecce - Italy).