© Vibracoustic © BENTELER

General |

Benteler and Vibracoustic team up for e-mobility solutions

The two companies are joining forces to combine their competencies in the development of solutions for electromobility.

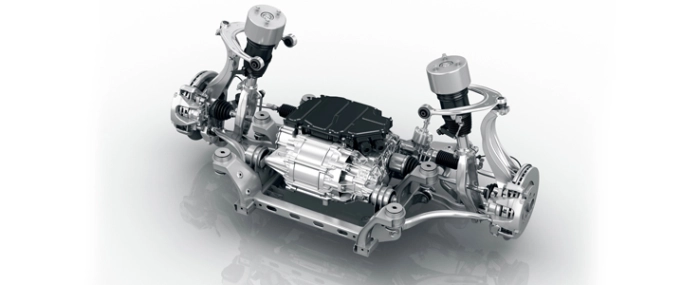

Benteler provides know-how on chassis and system integration and Vibracoustic its expertise in reducing noise and vibration and the design of chassis and motor mounts; which will result in noise- and vibration-optimised chassis solutions for electric vehicles.

Car manufacturers can speed up their development cycles as they can rely on a system which is already tuned by Vibracoustic in terms of NVH (Noise, Vibration, Harshness), to support optimum ride and handling. This pre-validated front and rear axle system aims to guarantees customers high functionality and quality in their electric vehicles. In addition, thanks to the partnership, customers benefit from accelerated time-to-market and easy adaptation for a wide range of vehicle classes, a press release reads.

“To develop our e-mobility solutions according to the customers’ needs, we use an agile, collaborative network approach with strategic partners like Vibracoustic,” says Marco Kollmeier, Vice President Business Unit Electro-Mobility at Benteler Automotive. “Thus we are able to provide customers with modular and tailor-made e-mobility solutions.”

Frank Mueller, CEO of Vibracoustic, adds: “Comfort is crucial to the overall driving experience and therefore the partnership between Benteler and Vibracoustic is a perfect fit. With our combined competencies, we can offer customers a pre-validated front and rear axle system which is already tuned for great driving comfort and handling.”