© mekoprint

Electronics Production |

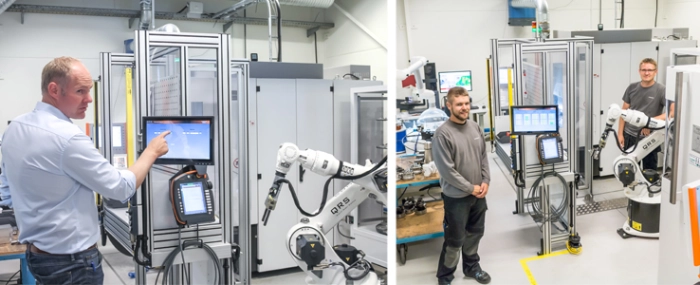

Mekoprints highly automated mini factory is open for businesses

The Danish company has inaugurated its new mini factory – capable of running 24/7 – in Støvring in the northern parts of the Jutland peninsula.

Mekoprint Chemigrapchis has for many years supplied precision metal components based on etching, punching and bending technology – and now with the inagration of the mini-factory, the company is adding milling technology to the mix.

Two five-axis Micron micro milling machines from Masentia with an auxiliary Kuka Robot, supplied by QRS, are set in a climate controlled room where the temperature is controlled within +/- 1 degree celcius.

“With this we have created an efficient setup that allows us to produce components 24 hours, seven days a week,” design and development manager Bjørn Mølbach Krogh says in a press release and elaborates.

“We have created a mini-factory within the factory, which will also inspire further automation in our existing factory and thus act as a catalyst of automation in general. Automation is necessary, not only to maintain but in particular to increase competitiveness. We now have the opportunity to produce a combination of high and low volume in the same production cell.”