© ucamco

PCB |

Ruwel and tw-elektric jump ahead of the Direct Imaging game

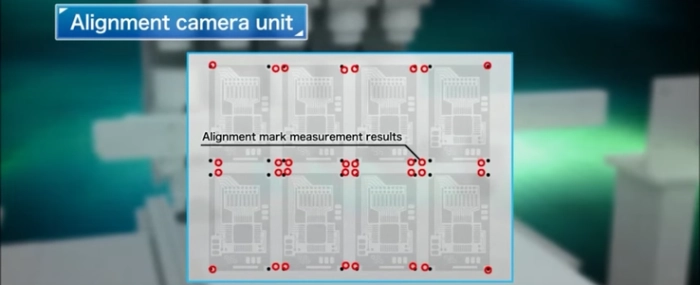

PCB manufacturers Ruwel and tw-elektric Horst Müller GmbH & Co. KG have integrated their Ledia direct imaging machines from Ucamco with autoloading solutions from ASS Luippold.

Ruwel and tw-elektric Horst Müller GmbH & Co. KG, two PCB manufacturers with very different manufacturing environments, have integrated their existing Ledia Direct Imaging systems into automatic imaging lines using Autoloaders tailored to their individual needs by ASS Luippold.

At Ruwel, Ledia is used for imaging soldermask on medium sized jobs, with each panel taking up to 60 seconds to image. Here, ASS housed the Ledia within an in-line linear axis system integrated into a conventional conveyor line. Panels are transferred between the conveyor, the autoloader and Ledia by a single arm moving in simple horizontal, vertical and rotational axes.

tw-elektric Horst Müller GmbH & Co. KG uses its Ledia to process much faster inner- and outerlayer dry film resists in a high-mix very low volume and prototype production environment, so ASS installed a faster more flexible off-line autoloading system whose two highly versatile high-speed 6- axis robot arms can execute multiple complex tasks in parallel.

In both cases, incoming panels are placed on a pre-centering table where they are cleaned before moving to the Ledia for imaging. tw-elektric Horst Müller GmbH & Co. KG's system also inspects each panel's fiducials then places it within microns of its optimum position on the Ledia for increased imaging throughput.