© optomec

Electronics Production |

Optomec 3D printing systems used by LITE-ON

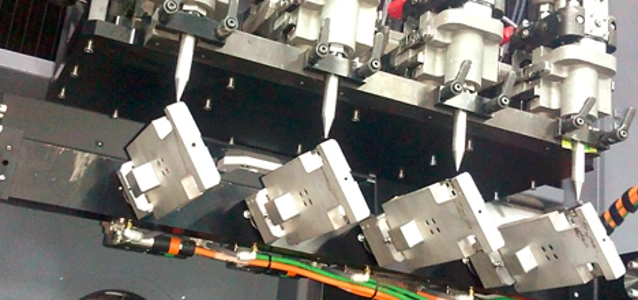

Optomec's, a supplier of additive manufacturing systems for 3D printed metals and 3D printed electronics, Aerosol Jet technology is being used by LITE-ON Mobile Mechanical for high-volume production of electronic devices.

LITE-ON, a global contract manufacturer, is utilising a 3D Direct Printing (3DP) solution that enables 3D antenna patterns and other functional electronics to be integrated into virtually any mechanical structure or cover.

“With the flexibility provided by Aerosol Jet technology, our 3DP systems can print sensors, antennas, and other functional electronics onto plastic components and covers, as well as metal die-cast insert-molded polymer frames, and even onto glass panels and ceramic materials,” said Henrik Johansson, Senior Manager, Technology Development Antennas, at LITE-ON. “We see Aerosol Jet as a strategic component of our 3DP solution, which has enabled us to expand into new markets.”

LITE-ON first purchased Aerosol Jet technology to develop prototypes for its OEM customers, which include communication devices, personal care and automotive brands. After successfully implementing the system in prototype environments, LITE-ON expanded its usage and has now deployed multiple production machines in Guangzhou, China, operating 24x7 printing conformal electronics onto millions of consumer devices.

“LITE-ON has been an incredible strategic customer for Optomec. Their dedication and commitment was critical to proving the viability of Aerosol Jet technology in a real world 24/7 production setting,” said Dave Ramahi, Optomec President and CEO. “With its unique and in-depth process knowledge in Aerosol Jet printing, Optomec is pleased to recognize LITE-ON as a 'Center of Excellence' for High Volume Production of 3D Printed Electronics.”