© carbon3d

Electronics Production |

Liquid 3D printing - this is pure SciFi

Like most of you have figured, my inner geek get's butterflies from desktop equipment and 3D printers, and I am one of those that screams about how this will be the revolution. But this one, this is just SciFi.

Carbon3D is a Silicon Valley based company (where else), working on marrying the intricacies of molecular science with hardware and software technologies to bring the 3D printing industry beyond basic prototyping to 3D manufacturing.

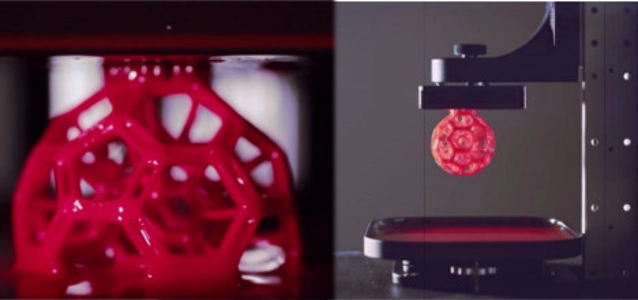

Remember T-1000 from the Terminator 2? The T-1000 body was composed of liquid metal which allowed it to assume the form of other objects, like a shapeshifter. Carbon3D's printer utilises something called CLIP technology (Continuous Liquid Interface Production) which harnesses light and oxygen to continuously grow objects from a pool of resin instead of printing them layer-by-layer. Maybe not the same as the T-1000, but looks like something out of a movie.

“Current 3D printing technology has failed to deliver on its promise to revolutionize manufacturing,” said Dr. Joseph DeSimone, CEO and Co-Founder, Carbon3D. “Our CLIP technology offers the game-changing speed, consistent mechanical properties and choice of materials required for complex commercial quality parts.”

Speed and resolution have been something of a sore thumb when it comes to 3D printer. Existing 3D printing, or additive manufacturing, technology is in some ways just 2D printing, over and over again. As a result, 3D printed parts take many hours, even days, to produce.

However, Carbon3D claims that their technology makes its printing 25-100 times faster than conventional 3D printing.

Using a tunable photochemical process instead of the traditional mechanical approach, Carbon3D’s layerless continuous liquid interface production technology (CLIP) can rapidly transform 3D models into physical objects. By balancing the interaction of UV light, which triggers photo polymerization, and oxygen, which inhibits the reaction, CLIP continuously grows objects from a pool of resin at speeds 25-100 times faster than traditional 3D printing. At the heart of the CLIP process is a special window that is transparent to light and permeable to oxygen, much like a contact lens. By controlling the oxygen flux through the window, CLIP creates a “dead zone” in the resin pool just tens of microns thick (about 2-3 diameters of a red blood cell) where photopolymerization cannot occur. As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone, the company explains in a press release. ---- Images and Video © Carbon3DClick to zoom