© alexander podshivalov dreamstime.com

PCB |

Smart PCB Sourcing Concepts

Whether you are an EMS, or an OEM, defining the right sourcing policy for PCBs and components is an important strategic management task. Making a forward-looking decision creates results that help improve company’s competitiveness.

Take a large EMS companies that has a PCB purchasing volume in the order of half a billion USD. A holistic approach to draw on all available efficiency boosters in the companies’ sourcing environment (organizational set-up and purchasing efforts) will award the bottom line with single or double digit million savings. It is worth pursuing a smart PCB sourcing concept.

Classifying your PCB Purchasing Portfolio

Before defining a sourcing policy one has to know the “DNA” of the purchasing portfolio. One way of analyzing it is to cluster it into two major groups – technology and volume requirements. There is also an additional option to classify into a third major group – business segment – for additional structure.

Recommended technology subcategories are: rigid boards, flexible/rigid-flex boards, heavy copper, HDI, IMS requirements. The 2nd group, the volume category, may be clustered as low, medium and high volume groups.

Having classified your portfolio, you need to find an efficient sourcing strategy which ought to be implemented tactically by the procurement department.

Purchasing Demand meets Market Supply Situation

The requirements of an often highly diversified PCB portfolio (technically and lot sizes necessities) traditionally meets a very different market reality on the supply side. PCB producers are often strong technically and commercially in mainly one particular PCB segment, e.g. low layer rigid boards only, or high volumes only, or flexible boards and low volumes only. This will not cover a wide and diversified PCB portfolio.

Sure there are producer around that offer multiple volumes and technologies from one source. However, one has to answer the question: Does this “Jack of all trades” situation always offer me the most reliable and competitive solution?

If you believe the answer to this question is “no”, naturally your sourcing policy tends to require a multiple sourcing strategy. If you believe the answer to this question is “yes”, naturally your sourcing policy tends to require a single sourcing strategy. Which sourcing strategy is the best and what are the strength and weaknesses?

Sourcing Options

Mainly there are four different approaches to sourcing:

Focusing collaboration on a narrowed down basket of suppliers drives the level of collaboration beyond just linking information systems. The final target is fully integrating business processes and organization structures across companies that comprise the full value chain. Today’s SCM moves from pure execution (i.e. event driven) to a more information and relationship intense focus. SCM is a vital core strategy and needs smart talents to shape it.

The Third Way – Sourcing from a large credible fabless PCB provider

From the above explanations we learn that single as well as multiple sourcing have complementary advantages as well as challenges. Utilizing exclusively one or the other sourcing strategy will never benefit the customer with the combined advantages of the two models.

The consequential question must be: Is there an alternative sourcing option that cumulates the advantages and minimizes the disadvantages of the two strategies?

The answer is yes.

The combined sourcing benefits can be harvested if sourcing from a fabless PCB provider.

What are the attributes of a fabless PCB provider?

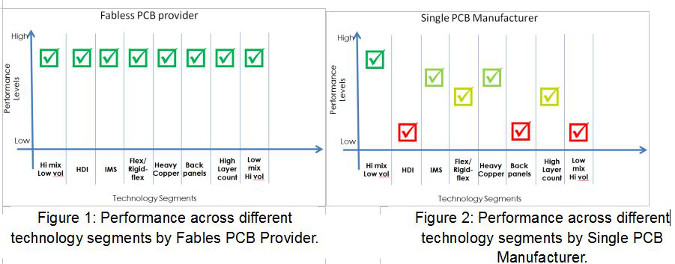

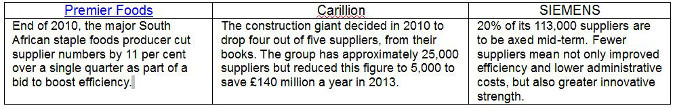

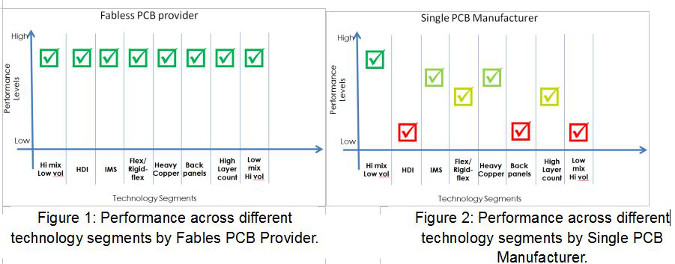

A credible “Fabless PCB Provider” owns everything that is needed to produce PCBs, but the factories. Instead of a factory, the provider has a portfolio of production partners. This portfolio is strategically developed and assembled over years. Ideally, it consists of partners with little overlap in the selected technology segments with best-in-class performance in the individual disciplines (figure 1). In contrast, look at the performance situation of one typical single PCB manufacturer (figure 2).

Focusing collaboration on a narrowed down basket of suppliers drives the level of collaboration beyond just linking information systems. The final target is fully integrating business processes and organization structures across companies that comprise the full value chain. Today’s SCM moves from pure execution (i.e. event driven) to a more information and relationship intense focus. SCM is a vital core strategy and needs smart talents to shape it.

The Third Way – Sourcing from a large credible fabless PCB provider

From the above explanations we learn that single as well as multiple sourcing have complementary advantages as well as challenges. Utilizing exclusively one or the other sourcing strategy will never benefit the customer with the combined advantages of the two models.

The consequential question must be: Is there an alternative sourcing option that cumulates the advantages and minimizes the disadvantages of the two strategies?

The answer is yes.

The combined sourcing benefits can be harvested if sourcing from a fabless PCB provider.

What are the attributes of a fabless PCB provider?

A credible “Fabless PCB Provider” owns everything that is needed to produce PCBs, but the factories. Instead of a factory, the provider has a portfolio of production partners. This portfolio is strategically developed and assembled over years. Ideally, it consists of partners with little overlap in the selected technology segments with best-in-class performance in the individual disciplines (figure 1). In contrast, look at the performance situation of one typical single PCB manufacturer (figure 2).

Sourcing from a large credible fabless PCB provider helps you benefit from the combined advantages of both traditional sourcing strategies – single sourcing and multiple sourcing.

A credible fabless PCB provider is your single pivot point engaging multiple factories that are all tailored optimally for your required PCB technologies.

If your company agrees with W. Edwards Deming’s 14 points for management then following the approach “The Third Way – Sourcing from fabless PCB provider” come only as a natural result.

In the 1950s, Deming had major impact on the manufacturing and business world in Japan. Many of his 14 points are embedded in the concept and goals of sourcing through a credible fabless PCB provider.

Since a fabless PCB provider has everything that is needed to produce PCBs, but a factory, he will concentrate 100% on all supporting tasks with Deming’s 14 points in mind.

Using a fabless PCB provider as your single point of purchase and project manager for all PCB supply related tasks (quality, logistics, factory audits, technology scout, even PCB education), you are able to turn a supplier relationship into a value creating long-term learning relationship.

The elimination of multiple and repetitive processes (e.g. scouting for suppliers, contract negotiations with each and every supplier, multiple supplier management, implementing standardized quality requirements across all suppliers) in your organization is another building block to keep your own SCM organizations lean and focused on core competencies.

Reduce internal processes and use bundled sourcing through a credible fabless PCB provider.

Cost Consideration

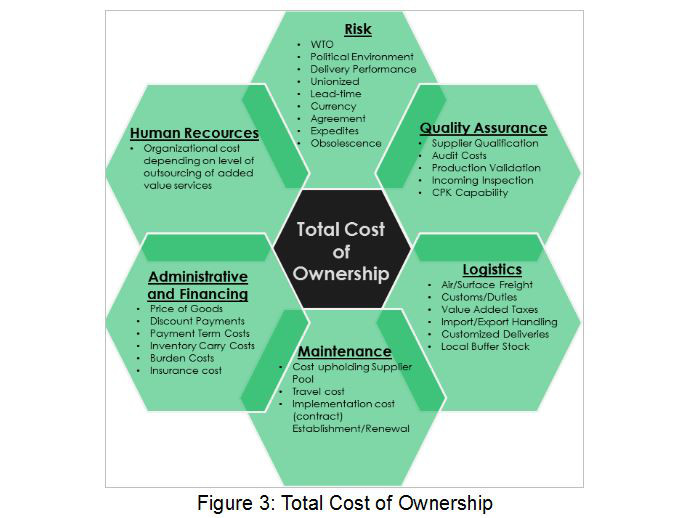

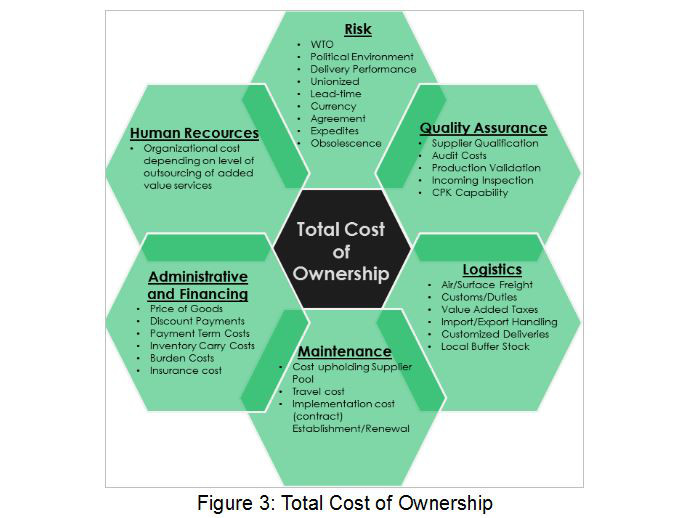

A reactive PCB supply chain manager was yesterday. Today, he/she pro-actively manages the strategic supply chain, or more precisely the Total Cost of Ownership (TCO)- see figure 3

Sourcing from a large credible fabless PCB provider helps you benefit from the combined advantages of both traditional sourcing strategies – single sourcing and multiple sourcing.

A credible fabless PCB provider is your single pivot point engaging multiple factories that are all tailored optimally for your required PCB technologies.

If your company agrees with W. Edwards Deming’s 14 points for management then following the approach “The Third Way – Sourcing from fabless PCB provider” come only as a natural result.

In the 1950s, Deming had major impact on the manufacturing and business world in Japan. Many of his 14 points are embedded in the concept and goals of sourcing through a credible fabless PCB provider.

Since a fabless PCB provider has everything that is needed to produce PCBs, but a factory, he will concentrate 100% on all supporting tasks with Deming’s 14 points in mind.

Using a fabless PCB provider as your single point of purchase and project manager for all PCB supply related tasks (quality, logistics, factory audits, technology scout, even PCB education), you are able to turn a supplier relationship into a value creating long-term learning relationship.

The elimination of multiple and repetitive processes (e.g. scouting for suppliers, contract negotiations with each and every supplier, multiple supplier management, implementing standardized quality requirements across all suppliers) in your organization is another building block to keep your own SCM organizations lean and focused on core competencies.

Reduce internal processes and use bundled sourcing through a credible fabless PCB provider.

Cost Consideration

A reactive PCB supply chain manager was yesterday. Today, he/she pro-actively manages the strategic supply chain, or more precisely the Total Cost of Ownership (TCO)- see figure 3

The analysis of customer requirements provides the basis for determining the cost drivers associated with purchasing the product and service. The supply chain manager has the right to expect product and services of the “right quality, from the right supplier, in the right quantity, at the right time, and at the right price.”

But what is the most and least important factor of all the expected “rights…”?.

A value stream mapping exercise comes to the rescue as it identifies the cost drivers to deliver product and services. Once identified what most and what is least important, the SCM must work closely with the PCB provider to shape a TCO model for its individual case and eliminate non-value added activities.

We need to understand that, what is regarded as value-added can be different under various circumstances. The author’s publication “PCBs from Asia traded by western PCB manufacturer” proves the above. The customer, “PCB manufacturer”, souring from a fabless PCB provider can have a very different TCO model than, for example, an EMS supplier. The “PCB manufacturer” may not want the product qualification (e.g. climate chamber, temp cycling tests) to be done by the PCB provider. Since he is in a similar business to the fabless PCB provider, he might want to use his own test lab and does not require this service from the fabless PCB provider.

A successful supply chain manager knows how to find a trustworthy PCB supply partner who offers the most flexible solutions to meet the ever-changing customer requirements.

He/she understands the trend that it’s not the big that eat the small, but it’s the fast that eats the slow. Cooperating with a fabless PCB provider who offers individualized solution can be a further benefit. Individually picking services that are important to have available locally (yellow part in Figure 4) vs. those services (lesser importance – faded part in Figure 4) that can be provided from offshore locations at a different price point, can help shaping your individual TCO situation. It ranks services according to importance, keeping the one that are essential close to you.

The results: An individualized, lean, efficient and dynamic outsourcing solution.

The analysis of customer requirements provides the basis for determining the cost drivers associated with purchasing the product and service. The supply chain manager has the right to expect product and services of the “right quality, from the right supplier, in the right quantity, at the right time, and at the right price.”

But what is the most and least important factor of all the expected “rights…”?.

A value stream mapping exercise comes to the rescue as it identifies the cost drivers to deliver product and services. Once identified what most and what is least important, the SCM must work closely with the PCB provider to shape a TCO model for its individual case and eliminate non-value added activities.

We need to understand that, what is regarded as value-added can be different under various circumstances. The author’s publication “PCBs from Asia traded by western PCB manufacturer” proves the above. The customer, “PCB manufacturer”, souring from a fabless PCB provider can have a very different TCO model than, for example, an EMS supplier. The “PCB manufacturer” may not want the product qualification (e.g. climate chamber, temp cycling tests) to be done by the PCB provider. Since he is in a similar business to the fabless PCB provider, he might want to use his own test lab and does not require this service from the fabless PCB provider.

A successful supply chain manager knows how to find a trustworthy PCB supply partner who offers the most flexible solutions to meet the ever-changing customer requirements.

He/she understands the trend that it’s not the big that eat the small, but it’s the fast that eats the slow. Cooperating with a fabless PCB provider who offers individualized solution can be a further benefit. Individually picking services that are important to have available locally (yellow part in Figure 4) vs. those services (lesser importance – faded part in Figure 4) that can be provided from offshore locations at a different price point, can help shaping your individual TCO situation. It ranks services according to importance, keeping the one that are essential close to you.

The results: An individualized, lean, efficient and dynamic outsourcing solution.

What’s the take-away?

The learning curve costs for your organization is minimized when you go with the third sourcing approach “sourcing through a fabless PCB provider” – explained in this article.

One of the fabless producer’s added-value come from: being specialized in most efficiently managing a complementary pool of multiple PCB producers. A fabless producer lives it breathes it. It is his daily bread.

Engaging Total Cost of Ownership models provides the sourcing professional the arguments that sourcing through a fabless PCB provider offers the highest flexibility with the lowest maintenance cost of possible outsourcing models.

Forward looking SCM strategists are beginning to discover the value for them more and more. Proof lies in the positive turnover development of fabless companies. In the last five years credible fabless PCB provider grew always above market. In general the growth was double digits.

During daily work with clients from around the world, it can be seen more and more that a single point of sales is preferred over multiple points of sales. The convenience factor for the SCM is the highest with this model.

-----

Author: Theo Langer,VP Sales Asia & Sales Coordinator Worldwide for © CML in Hong Kong and China.

What’s the take-away?

The learning curve costs for your organization is minimized when you go with the third sourcing approach “sourcing through a fabless PCB provider” – explained in this article.

One of the fabless producer’s added-value come from: being specialized in most efficiently managing a complementary pool of multiple PCB producers. A fabless producer lives it breathes it. It is his daily bread.

Engaging Total Cost of Ownership models provides the sourcing professional the arguments that sourcing through a fabless PCB provider offers the highest flexibility with the lowest maintenance cost of possible outsourcing models.

Forward looking SCM strategists are beginning to discover the value for them more and more. Proof lies in the positive turnover development of fabless companies. In the last five years credible fabless PCB provider grew always above market. In general the growth was double digits.

During daily work with clients from around the world, it can be seen more and more that a single point of sales is preferred over multiple points of sales. The convenience factor for the SCM is the highest with this model.

-----

Author: Theo Langer,VP Sales Asia & Sales Coordinator Worldwide for © CML in Hong Kong and China.

- Sole sourcing (only one supplier in the supplier base – e.g. because of a patent)

- Single sourcing (one single supplier is selected out of a choice of suppliers)

- Dual sourcing (two suppliers are selected)

- Multiple sourcing (multiple suppliers are selected)

Focusing collaboration on a narrowed down basket of suppliers drives the level of collaboration beyond just linking information systems. The final target is fully integrating business processes and organization structures across companies that comprise the full value chain. Today’s SCM moves from pure execution (i.e. event driven) to a more information and relationship intense focus. SCM is a vital core strategy and needs smart talents to shape it.

The Third Way – Sourcing from a large credible fabless PCB provider

From the above explanations we learn that single as well as multiple sourcing have complementary advantages as well as challenges. Utilizing exclusively one or the other sourcing strategy will never benefit the customer with the combined advantages of the two models.

The consequential question must be: Is there an alternative sourcing option that cumulates the advantages and minimizes the disadvantages of the two strategies?

The answer is yes.

The combined sourcing benefits can be harvested if sourcing from a fabless PCB provider.

What are the attributes of a fabless PCB provider?

A credible “Fabless PCB Provider” owns everything that is needed to produce PCBs, but the factories. Instead of a factory, the provider has a portfolio of production partners. This portfolio is strategically developed and assembled over years. Ideally, it consists of partners with little overlap in the selected technology segments with best-in-class performance in the individual disciplines (figure 1). In contrast, look at the performance situation of one typical single PCB manufacturer (figure 2).

Focusing collaboration on a narrowed down basket of suppliers drives the level of collaboration beyond just linking information systems. The final target is fully integrating business processes and organization structures across companies that comprise the full value chain. Today’s SCM moves from pure execution (i.e. event driven) to a more information and relationship intense focus. SCM is a vital core strategy and needs smart talents to shape it.

The Third Way – Sourcing from a large credible fabless PCB provider

From the above explanations we learn that single as well as multiple sourcing have complementary advantages as well as challenges. Utilizing exclusively one or the other sourcing strategy will never benefit the customer with the combined advantages of the two models.

The consequential question must be: Is there an alternative sourcing option that cumulates the advantages and minimizes the disadvantages of the two strategies?

The answer is yes.

The combined sourcing benefits can be harvested if sourcing from a fabless PCB provider.

What are the attributes of a fabless PCB provider?

A credible “Fabless PCB Provider” owns everything that is needed to produce PCBs, but the factories. Instead of a factory, the provider has a portfolio of production partners. This portfolio is strategically developed and assembled over years. Ideally, it consists of partners with little overlap in the selected technology segments with best-in-class performance in the individual disciplines (figure 1). In contrast, look at the performance situation of one typical single PCB manufacturer (figure 2).

Sourcing from a large credible fabless PCB provider helps you benefit from the combined advantages of both traditional sourcing strategies – single sourcing and multiple sourcing.

A credible fabless PCB provider is your single pivot point engaging multiple factories that are all tailored optimally for your required PCB technologies.

If your company agrees with W. Edwards Deming’s 14 points for management then following the approach “The Third Way – Sourcing from fabless PCB provider” come only as a natural result.

In the 1950s, Deming had major impact on the manufacturing and business world in Japan. Many of his 14 points are embedded in the concept and goals of sourcing through a credible fabless PCB provider.

Since a fabless PCB provider has everything that is needed to produce PCBs, but a factory, he will concentrate 100% on all supporting tasks with Deming’s 14 points in mind.

Using a fabless PCB provider as your single point of purchase and project manager for all PCB supply related tasks (quality, logistics, factory audits, technology scout, even PCB education), you are able to turn a supplier relationship into a value creating long-term learning relationship.

The elimination of multiple and repetitive processes (e.g. scouting for suppliers, contract negotiations with each and every supplier, multiple supplier management, implementing standardized quality requirements across all suppliers) in your organization is another building block to keep your own SCM organizations lean and focused on core competencies.

Reduce internal processes and use bundled sourcing through a credible fabless PCB provider.

Cost Consideration

A reactive PCB supply chain manager was yesterday. Today, he/she pro-actively manages the strategic supply chain, or more precisely the Total Cost of Ownership (TCO)- see figure 3

Sourcing from a large credible fabless PCB provider helps you benefit from the combined advantages of both traditional sourcing strategies – single sourcing and multiple sourcing.

A credible fabless PCB provider is your single pivot point engaging multiple factories that are all tailored optimally for your required PCB technologies.

If your company agrees with W. Edwards Deming’s 14 points for management then following the approach “The Third Way – Sourcing from fabless PCB provider” come only as a natural result.

In the 1950s, Deming had major impact on the manufacturing and business world in Japan. Many of his 14 points are embedded in the concept and goals of sourcing through a credible fabless PCB provider.

Since a fabless PCB provider has everything that is needed to produce PCBs, but a factory, he will concentrate 100% on all supporting tasks with Deming’s 14 points in mind.

Using a fabless PCB provider as your single point of purchase and project manager for all PCB supply related tasks (quality, logistics, factory audits, technology scout, even PCB education), you are able to turn a supplier relationship into a value creating long-term learning relationship.

The elimination of multiple and repetitive processes (e.g. scouting for suppliers, contract negotiations with each and every supplier, multiple supplier management, implementing standardized quality requirements across all suppliers) in your organization is another building block to keep your own SCM organizations lean and focused on core competencies.

Reduce internal processes and use bundled sourcing through a credible fabless PCB provider.

Cost Consideration

A reactive PCB supply chain manager was yesterday. Today, he/she pro-actively manages the strategic supply chain, or more precisely the Total Cost of Ownership (TCO)- see figure 3

The analysis of customer requirements provides the basis for determining the cost drivers associated with purchasing the product and service. The supply chain manager has the right to expect product and services of the “right quality, from the right supplier, in the right quantity, at the right time, and at the right price.”

But what is the most and least important factor of all the expected “rights…”?.

A value stream mapping exercise comes to the rescue as it identifies the cost drivers to deliver product and services. Once identified what most and what is least important, the SCM must work closely with the PCB provider to shape a TCO model for its individual case and eliminate non-value added activities.

We need to understand that, what is regarded as value-added can be different under various circumstances. The author’s publication “PCBs from Asia traded by western PCB manufacturer” proves the above. The customer, “PCB manufacturer”, souring from a fabless PCB provider can have a very different TCO model than, for example, an EMS supplier. The “PCB manufacturer” may not want the product qualification (e.g. climate chamber, temp cycling tests) to be done by the PCB provider. Since he is in a similar business to the fabless PCB provider, he might want to use his own test lab and does not require this service from the fabless PCB provider.

A successful supply chain manager knows how to find a trustworthy PCB supply partner who offers the most flexible solutions to meet the ever-changing customer requirements.

He/she understands the trend that it’s not the big that eat the small, but it’s the fast that eats the slow. Cooperating with a fabless PCB provider who offers individualized solution can be a further benefit. Individually picking services that are important to have available locally (yellow part in Figure 4) vs. those services (lesser importance – faded part in Figure 4) that can be provided from offshore locations at a different price point, can help shaping your individual TCO situation. It ranks services according to importance, keeping the one that are essential close to you.

The results: An individualized, lean, efficient and dynamic outsourcing solution.

The analysis of customer requirements provides the basis for determining the cost drivers associated with purchasing the product and service. The supply chain manager has the right to expect product and services of the “right quality, from the right supplier, in the right quantity, at the right time, and at the right price.”

But what is the most and least important factor of all the expected “rights…”?.

A value stream mapping exercise comes to the rescue as it identifies the cost drivers to deliver product and services. Once identified what most and what is least important, the SCM must work closely with the PCB provider to shape a TCO model for its individual case and eliminate non-value added activities.

We need to understand that, what is regarded as value-added can be different under various circumstances. The author’s publication “PCBs from Asia traded by western PCB manufacturer” proves the above. The customer, “PCB manufacturer”, souring from a fabless PCB provider can have a very different TCO model than, for example, an EMS supplier. The “PCB manufacturer” may not want the product qualification (e.g. climate chamber, temp cycling tests) to be done by the PCB provider. Since he is in a similar business to the fabless PCB provider, he might want to use his own test lab and does not require this service from the fabless PCB provider.

A successful supply chain manager knows how to find a trustworthy PCB supply partner who offers the most flexible solutions to meet the ever-changing customer requirements.

He/she understands the trend that it’s not the big that eat the small, but it’s the fast that eats the slow. Cooperating with a fabless PCB provider who offers individualized solution can be a further benefit. Individually picking services that are important to have available locally (yellow part in Figure 4) vs. those services (lesser importance – faded part in Figure 4) that can be provided from offshore locations at a different price point, can help shaping your individual TCO situation. It ranks services according to importance, keeping the one that are essential close to you.

The results: An individualized, lean, efficient and dynamic outsourcing solution.

What’s the take-away?

The learning curve costs for your organization is minimized when you go with the third sourcing approach “sourcing through a fabless PCB provider” – explained in this article.

One of the fabless producer’s added-value come from: being specialized in most efficiently managing a complementary pool of multiple PCB producers. A fabless producer lives it breathes it. It is his daily bread.

Engaging Total Cost of Ownership models provides the sourcing professional the arguments that sourcing through a fabless PCB provider offers the highest flexibility with the lowest maintenance cost of possible outsourcing models.

Forward looking SCM strategists are beginning to discover the value for them more and more. Proof lies in the positive turnover development of fabless companies. In the last five years credible fabless PCB provider grew always above market. In general the growth was double digits.

During daily work with clients from around the world, it can be seen more and more that a single point of sales is preferred over multiple points of sales. The convenience factor for the SCM is the highest with this model.

-----

Author: Theo Langer,VP Sales Asia & Sales Coordinator Worldwide for © CML in Hong Kong and China.

What’s the take-away?

The learning curve costs for your organization is minimized when you go with the third sourcing approach “sourcing through a fabless PCB provider” – explained in this article.

One of the fabless producer’s added-value come from: being specialized in most efficiently managing a complementary pool of multiple PCB producers. A fabless producer lives it breathes it. It is his daily bread.

Engaging Total Cost of Ownership models provides the sourcing professional the arguments that sourcing through a fabless PCB provider offers the highest flexibility with the lowest maintenance cost of possible outsourcing models.

Forward looking SCM strategists are beginning to discover the value for them more and more. Proof lies in the positive turnover development of fabless companies. In the last five years credible fabless PCB provider grew always above market. In general the growth was double digits.

During daily work with clients from around the world, it can be seen more and more that a single point of sales is preferred over multiple points of sales. The convenience factor for the SCM is the highest with this model.

-----

Author: Theo Langer,VP Sales Asia & Sales Coordinator Worldwide for © CML in Hong Kong and China.