© evertiq

PCB |

One resurrection please!

Quietly and out of sight, the German PCB manufacturer Ruwel has fought its way back into the market. Now, the company is slowly venturing back into the public eye.

Hard times lie behind the German PCB manufacturer Ruwel. Most – if not all – within the electronics industry know about that. But the company has come back.

After having talked to CEO Gerard van Dierendonck in April 2014, we decided to come back and have a closer look around the facility in Geldern. And – I swear on my mom's cooking – we left no stone unturned.

Ruwel is one of the PCB companies, which were able to fight their way back from bankruptcy and the economic crisis. The company is much smaller now (in many respects), but the economic success and the profitability have returned. “That, we own to our employees, but also to Unimicron, our Taiwanese mother”, said Hans-Gerd Vousten, Head of Sales at Ruwel.

But how do you turn a company with only one major customer into a manufacturer that serves many customers from different industry segments? “With patience and perseverance”; the management answers in unison. It is certainly not very often that an Asian company is so rigorously and actively engaged in Europe. Ruwel however had one decisive advantage: the production focus on Automotive. Something that Unimicron took note of.

The fears and uncertainties of the first hours are long past, says Hans-Gerd Vousten. Management and employees focused on rebuilding the company and its future. And that enthusiasm has remained with Ruwel to this day. This may also have something to do with the fact that Ruwel is currently busy spending EUR 10 million on improving the machine park. And that fact has made Rico Schlüter, Head of Technology, Wolfgang Burgermeister and Bart Kempen, both Head of Production, see things through rose-colored glasses at the moment.

"You can only really operate in the Top5, be successful and profitable, if you invest consistently and constantly, both in staff and in equipment. The development is fast-paced and you really need to invest continuously", as Rico Schlüter points out. And therefore the machinery park is being upgraded.

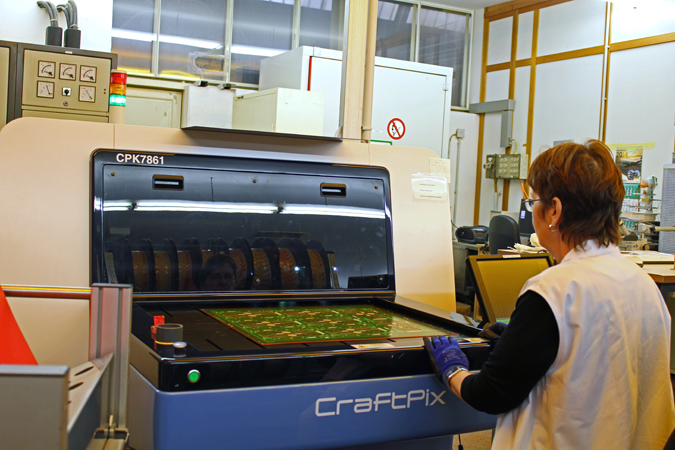

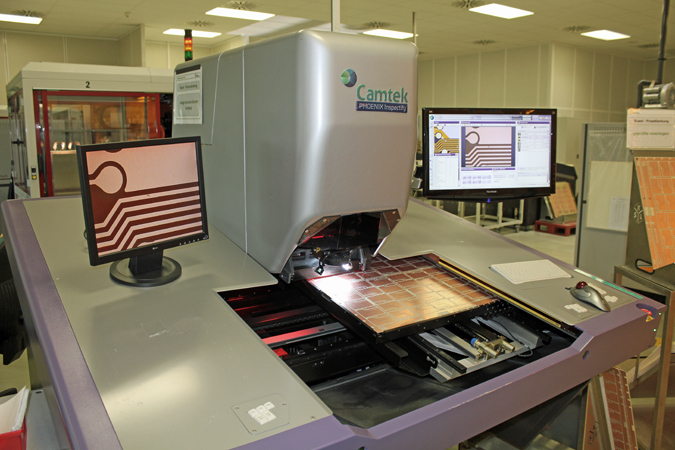

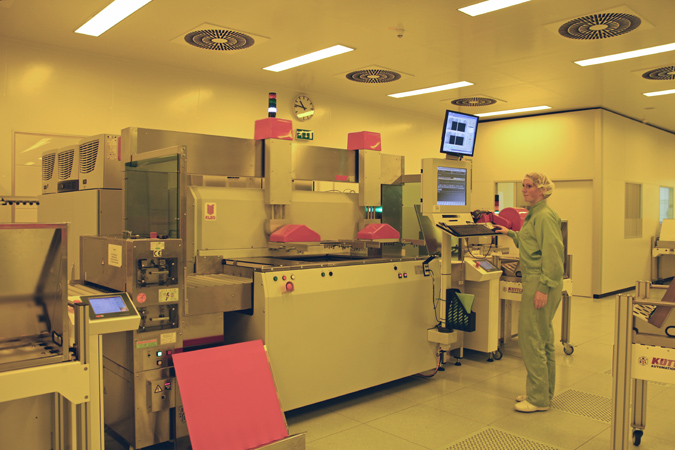

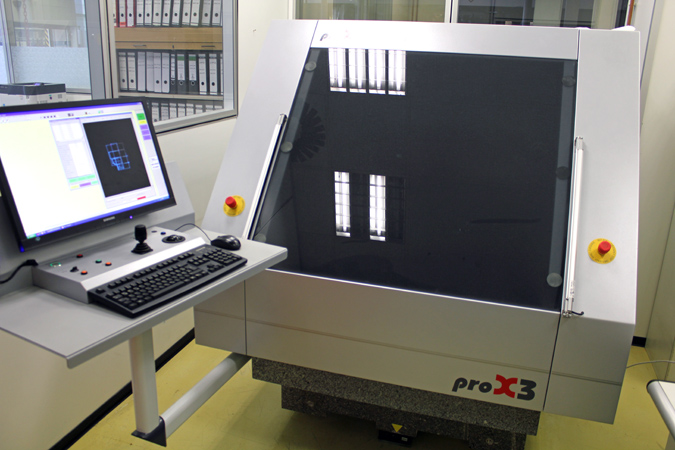

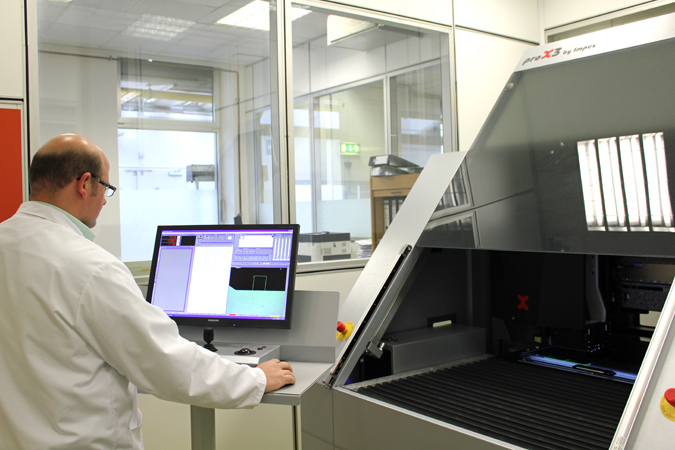

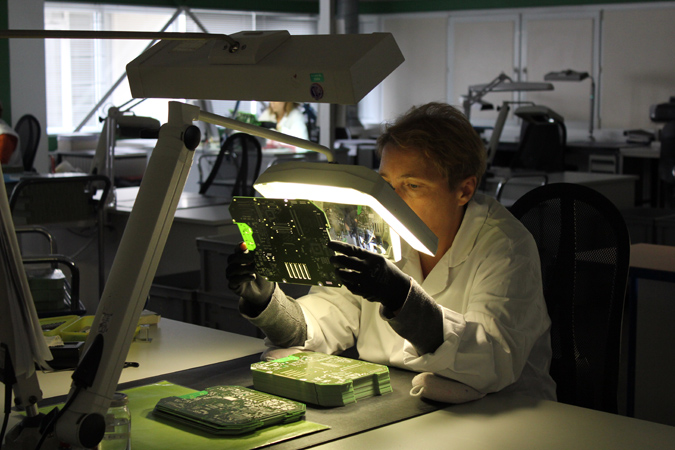

“Having already invested in an outer layer LDI in 2013, it was our priority to digitize our inner layer department in 2014. We invested in, among other things, a Hakuto dry film laminator, a second fully-automated KLEO LDI for the inner layer production (with a cycle time of just 8.6 seconds); we added a new Schmid Premium DES, two Camtek Phoenix AOIs, a Schmoll XRI X-ray drill and a DIS inner layer bonding machine. The testing department also received an upgrade; we invested in additional finger testers ATG A5 and ATG A7, as well as in an inkjet printer for labelling and the refurbishment of the lab area, to name but a few acquisitions.”

After our factory tour, I come back to my initial question about the customer portfolio. How do you go from two volume customers to a broader and more balanced customer base?

"Our goal is to produce for three industry sectors: renewable energy, automotive and industry. Away from a 100% focus on Automotive and towards a more balanced customer portfolio. With this approach we can, and I am convinced of that, be successful in this market. We have not yet reached that target, but we are on the right track", said Mr van Dierendonck.

So in the summer of 2013, Ruwel set out to implement this new business strategy. "The buyers for the large automotive companies are now all based in Chengdu, Hong Kong or Shanghai. Automotive continues to migrate very heavily towards Asia. That we all know. Therefore, we have decided to divide our attention between automotive and renewable energy, but also develop a much stronger focus on industrial customers in general”, explains Rico Schlüter.

In addition, many European industrial companies are very careful when it comes to protecting their development work. They want to keep that particular know-how close to heart and in Europe. In fact, contracts usually state that a transfer to Asia is strictly prohibited. Interesting and potential customers for a PCB manufacturer based in Geldern. "And the sales people seem to have worked overtime last year. We've been very successful in this area”, the management acknowledges.

The production, however, was focused on standard printed circuit boards; large volume at that. It did not meet the requirements of industrial customers. You had to be more advanced; at least when it came to production equipment. "With this in mind, we reported back to Unimicron. We would have to invest a lot of money. And here we did not mean EUR 1 or 2 million. We were talking about a much broader investment package spanning over several years. And Unimicron – to our delight – agreed”, said Mr. Schlüter. “Unimicron is a company that is strategically very well positioned, future-oriented and thus has long-term goals. This decision clearly shows that Unimicon means business when it comes to Ruwel. Unimicron has absolute confidence in its German subsidiary and this mindset can only lead to mutual success.”

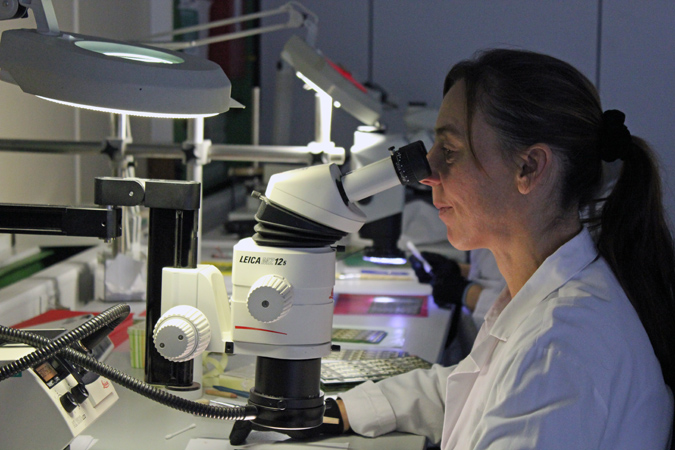

And Ruwel continued with its upgrading activities. “A new Ludy plating line was added, which makes it possible to meet the rapidly growing customer demand for printed circuit boards with blind vias (aspect ratio of 1: 1.3). And the older Dragon AOIs were replaced with new Camtek Phoenix HDI machines.”

And it does not stop there ....

“For early 2015, Ruwel plans to focus on solder mask and further investments. Last but not least, all remaining departments will be brought up to standard and get the future-ready stamp.”

“And all these changes happen alongside normal production work."

And this is not a stress-free process. "Long days for me and my colleagues. Have been for many months and it will continue for a while longer. However, I see it as positive stress.”

And why not. Unimicron has made a dream come true for Rico Schlüter. "In my 30 years within the PCB industry I have never seen anything like it. I thought I would never be able to build a production as I would envision it and how I would set up my own shop. And I can guarantee that Ruwel will look completely different next year."

Everyone at Ruwel is proud of the achievements and you can – if you want to trust an unbiased journalist – feel that sentiment if you should dare to visit Geldern yourself.

-----

Images © Ruwel

EDITOR'S NOTE_ The article continues after the gallery.