© andrzej thiel dreamstime.com

Electronics Production |

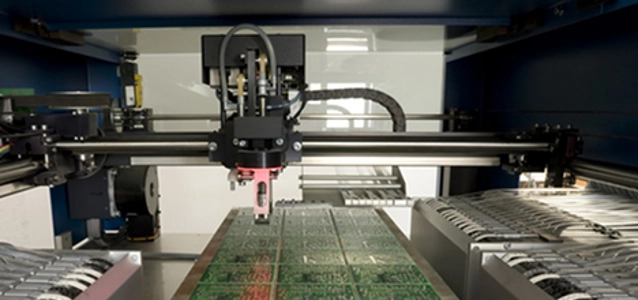

BMZ sets up production plant

BMZ GmbH will shortly start construction of Europe’s first highly automated rechargeable battery production plant at the company’s headquarters in Karlstein near Aschaffenburg.

It will be possible to almost fully automatically assemble, weld and test up to 200,000 rechargeable batteries to individual customer requirements annually in the 800 m² of the large new production facility’s first expansion stage, which is expected to be completed by the beginning of 2014. The investment costs are estimated to be around 5 million Euros.

BMZ founder and sole proprietor Sven Bauer sees the significant extension of production capacity at the Karlstein location as a further important milestone for the company. “A German company which wants to attain a long-term internationally top-ranking position in such an important future market as mobile energy supplies should not only rely on its innovative product ideas and its system expertise. With our highly efficient, highly automated rechargeable battery pack production facility we want to prove that BMZ in Germany is internationally competitive in all respects from a manufacturing point of view.”

The first expansion stage of the new production facility is already designed for a variety of battery sizes in the 200 g to 3 kg weight range. This enables both small units for domestic appliances and big batteries for e-bikes to be produced. Battery expert Bauer regards this as an important competitive advantage.

“The modular approach guarantees not only the largest possible flexibility with production planning and optimized utilization of production capacities but also contributes to further raising the quality of our products – all important pre-conditions to help consistently consolidate BMZ’s position as the leading European system supplier for intelligent lithium rechargeable battery solutions.”