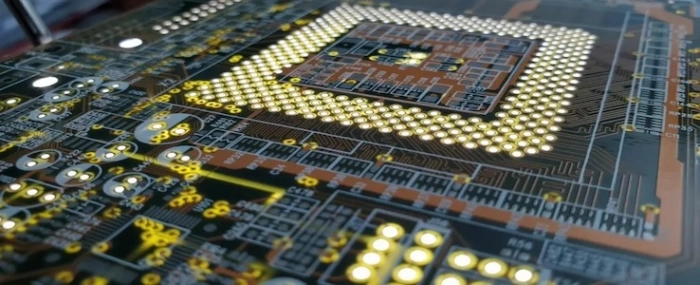

Why PCB raw materials matter: performance, reliability, and cost

ICAPE offers an overview of the key factors in PCB raw material selection and the considerations that guide their use.

Understanding the various raw materials used in printed circuit board (PCB) manufacturing is essential for optimizing performance, reliability, and cost-efficiency in electronic devices. Each PCB must meet application-specific requirements based on its operating environment, which makes it important to choose materials with the right properties. ICAPE Group has been producing and supplying PCBs since 1999. On their website, the company offers insight into key material considerations in the industry.

Substrates and copper layers

PCB raw materials consist of organic and inorganic substrates along with conductive copper layers. Organic substrates include paper cores impregnated with phenolic resins or woven/non-woven fiberglass fabrics impregnated with epoxy, polyimide, cyanate ester, or BT resins. Inorganic substrates include ceramics, aluminum, and copper-invar-copper.

The choice of organic substrate depends on the physical properties required by the PCB application – such as operating temperature, frequency, or mechanical strength. The use of inorganic materials is typically driven by the need for effective thermal management.

Types of PCB raw materials

The substrate forms the base to which copper is laminated, providing structural support for electronic components. Common substrate materials include FR-4, CEM-1, CEM-3, ceramic-filled hydrocarbons, PTFE, modified epoxy resins, BT (bismaleimide-triazine), aluminum, ceramics, and flexible materials.

Conductive materials are used to create traces, pads, and vias on the PCB surface. Copper is the most widely used conductive material due to its excellent electrical conductivity and affordable price. Silver and gold are also used for ceramic PCBs in specialized applications.

For high-frequency designs, advanced materials like modified epoxy resins and ceramic-filled hydrocarbons offer superior electrical performance, low dielectric loss, and thermal stability. RF and microwave applications may require ceramic-filled hydrocarbons or PTFE to meet stringent performance requirements.

Applications with high thermal demands often use IMS (Insulated Metal Substrate) designs, such as aluminum-based PCBs, due to their excellent heat dissipation. Ceramic PCBs are also suitable for high-temperature environments where thermal management is critical.

Flexible PCB materials like polyimide are ideal for compact or mobile applications, including wearable devices and medical implants.

Material selection is influenced by the application's demands, cost considerations, and performance specifications. Here is an overview of the most common PCB material types:

FR-4

The most commonly used PCB material, suitable for a wide range of applications including consumer electronics, automotive systems, industrial controls, military, and medical equipment.

Advantages:

- Excellent electrical insulation

- Good mechanical strength and dimensional stability

- Cost-effective

- Readily available

Disadvantages:

- Limited thermal conductivity

- Not suitable for punching

CEM-1

Typically used in low-cost consumer electronics and home appliances.

Advantages:

- Low cost

- Good for punching operations

Disadvantages:

- Not suitable for double-sided PCBs with plated through holes

CEM-3

Used in similar applications as CEM-1 but offers plated through hole capability. Suitable as a low-cost FR-4 alternative.

Disadvantages:

- Less readily available than FR-4

Modified Epoxy-Based FR-4

Commonly used in high-performance applications such as HDI (High Density Interconnect), aerospace, and telecommunications.

Advantages:

- Good electrical performance at higher frequencies

- Lower dielectric loss than standard FR-4

- Improved thermal stability

Disadvantages:

- Higher cost than standard FR-4

IMS PCBs (Insulated Metal Substrates)

Typically aluminum-based, used in applications requiring efficient thermal management, such as LED lighting, power supplies, and automotive electronics.

Advantages:

- Excellent thermal conductivity

- Lightweight

- Good dimensional stability

- Relatively low cost

Disadvantages:

- More difficult to process

- Complex to manufacture in multilayer designs

Flexible PCBs

Used in applications requiring mechanical flexibility or space constraints, such as wearables, medical devices, and automotive systems.

Advantages:

- Flexible and bendable

- Reduced size and weight

- Combined rigid-flex designs offer more reliable interconnections than separate rigid boards with cables

Disadvantages:

- More expensive than rigid PCBs

- Lower mechanical strength compared to rigid boards

Ceramic PCBs

Used in high-power and high-temperature applications such as power electronics, LED packaging, and sensors.

Advantages:

- Excellent thermal conductivity

- High-temperature resistance

- Excellent dimensional stability

Disadvantages:

- Higher cost than standard FR-4

- Brittle and requires careful handling during assembly

- Limited supplier capability for multilayer ceramic structures due to process complexity and extreme temperatures

- Difficult to process

Ceramic-Filled Hydrocarbons / PTFE

Used in high-frequency, high-performance applications such as RF/microwave circuits, aerospace, and telecom.

Advantages:

- Excellent electrical performance at high frequencies

- Low dielectric loss

- Good thermal stability

Disadvantages:

- Higher cost than FR-4

- Limited availability of specific formulations

Different PCBs require different raw materials

In conclusion, PCB raw materials – including substrates and conductive layers – are the foundational components of PCB manufacturing.

Common substrates include FR-4, CEM-1, CEM-3, ceramic-filled hydrocarbons, PTFE, modified epoxies, aluminum, ceramics, and flexible materials. Each offers specific properties suited to different applications.

Copper remains the most used conductive material due to its excellent conductivity and competitive cost. For ceramic PCBs, silver and gold are also used.

The benefits of ceramic-filled hydrocarbons or PTFE include their superior electrical performance, low dielectric loss, and thermal stability, making them ideal for microwave, millimeter-wave, and RF designs. Aluminum-based PCBs offer excellent heat dissipation and are well suited for LED lighting and power electronics.

Flexible substrates like polyimide provide design flexibility and reduce size and weight, ideal for compact or dynamic applications such as wearables and medical implants. Ceramic PCBs offer excellent heat dissipation, thermal resistance, and dimensional stability, making them ideal for high-temperature, high-power environments.

Overall, when selecting raw materials, key considerations include electrical performance, thermal management needs, mechanical durability, cost, and environmental impact.

.jpg)