Top 5 EMS trends that will shape the electronics industry in 2025

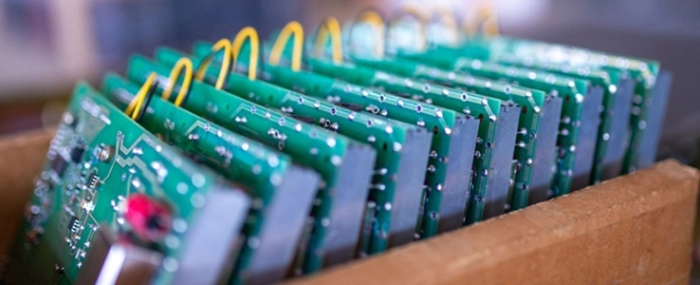

From prototype to mass production, the role of EMS in managing supply chains, ensuring scalability, and delivering high-quality products is expanding rapidly.

In 2025, EMS providers are no longer just production partners — they are strategic enablers. From prototype to mass production, the role of EMS in managing supply chains, ensuring scalability, and delivering high-quality products is expanding rapidly, according to a new report by Promwad, an independent electronics design house based in Europe.

Below are the top 5 EMS trends that will shape the electronics industry this year, according to Promwad:

1. Modular and configurable manufacturing lines

As OEMs demand faster turnaround, product personalization, and multi-SKU builds, EMS providers are shifting to modular, reconfigurable manufacturing cells.

This reduces line changeover time, supports multiple products with shared platforms, and enables faster NPI ramp-up.

2. Dual-region manufacturing models

The post-globalisation era has sparked a move away from single-point production. EMS providers are adopting dual-region and nearshoring models to reduce logistics risk and improve time-to-market.

Align your design files and BOMs with production transferability in mind.

3. Smart factories with AI-driven QA

Automation is maturing — not just in hardware handling, but in decision-making. In 2025, leading EMS sites are using AI for real-time quality assurance and predictive maintenance.

Emerging capabilities include vision-based inspection with ML classification, predictive yield analytics, and digital twins for production planning.

ROI impact includes reduced rework and scrap, real-time root cause detection, and more stable yields at scale.

4. Sustainability and circular manufacturing initiatives

Green production is no longer optional. EMS partners are investing in recyclable materials and low-impact sourcing; waste tracking and carbon reporting; and support for remanufacturing and extended product life.

5. Software-centric EMS collaboration

Firmware and test automation are now core to successful production — not side tasks. EMS providers increasingly offer support for OTA and secure boot workflows; embedded test scripting and remote logging tools; and early BSP and OS integration during prototyping

The boundary between hardware and software manufacturing is dissolving. OEMs must engage EMS partners who support full-stack integration — from board spin to cloud logging, the Promwad report says.