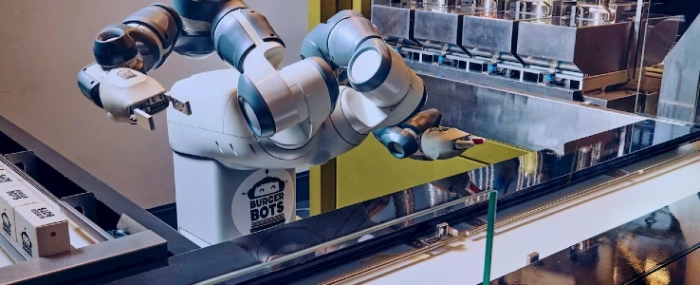

ABB's YuMi becomes a burger-flipping robot

ABB Robotics is serving up the future of fast food with BurgerBots – a robotics restaurant concept launched in Los Gatos, California. The automated kitchen uses ABB’s IRB 360 FlexPicker and YuMi collaborative robot.

“Integrating ABB robots with the BurgerBots restaurant concept demonstrates the incredible potential for automation beyond the factory floor,” said Marc Segura, President of ABB Robotics Division, in a press release. “The food service industry is dynamic and demanding, and our technology brings industrial-grade consistency, efficiency and reliability to this space.”

The compact robotic cell is a food automation first, integrating two types of robots with an intelligent inventory monitoring system. As each order is received, a freshly cooked burger patty is placed onto a bun inside a burger box. This box is then positioned on a conveyor shuttle, which is tagged with a QR code. As it moves along the conveyor, the IRB 360 FlexPicker performs high-speed topping selection, guided by the data stored in the QR code. Next, the YuMi steps in to collaborate on the final assembly of the burger. The entire process takes just 27 seconds per burger.

ABB’s robot controller also integrates with non-robotic systems, which enables real-time ingredient inventory tracking – onions, tomatoes, lettuce and condiments – ensuring smooth operations and efficient kitchen management.

BurgerBots is the brainchild of entrepreneur Elizabeth Truong, who sees the Los Gatos location as the first step in a broader commercial rollout.

“The vision was to bring consistency, transparency, and efficiency to food service. For restaurant owners, it means better visibility of food costs, more accurate forecasting and – ultimately – better decision making. In the next five years, I believe that most restaurants will have some form of robotic automation, whether it’s back-of-house preparation, assembly, or even front-of-house service. It will become less of a novelty and more of a necessity.”

.jpg)