SisTech selects Europlacer to power high-mix, high-rel growth

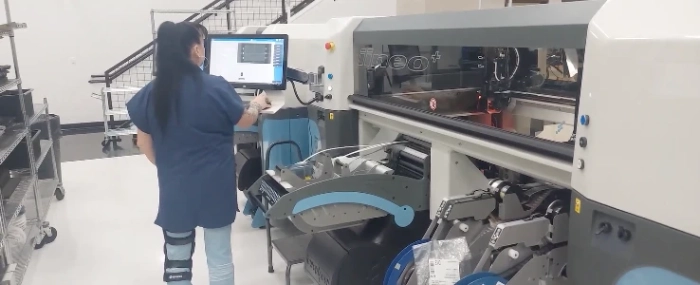

EMS provider SisTech Manufacturing continues to scale its capabilities with the help of Europlacer's placement platforms.

The Oregon-based electronics manufacturer serves industries including military, aerospace, medical, energy, and consumer electronics and is known for its low defect and scrap rate — under 1%. The company credits Europlacer's SMT equipment as a key enabler in scaling production while maintaining quality standards.

The company’s production includes a wide range of applications, from military communication headsets to gaming modules for Xbox and PlayStation, medical headlamps, and energy monitoring systems.

“The Europlacer platform is remarkably intuitive,” said Brad Kennedy, SisTech’s Founder and CEO. “We’ve trained completely new operators in under 20 minutes, and they’re outperforming experienced operators on other systems. That simplicity, combined with uptime and accuracy, allows us to meet complex demands head-on.””

SisTech’s operations involve frequent setup changes and high-mix production. According to Kennedy, Europlacer enables the team to meet those demands with both speed and precision. “We regularly do multiple job setups a day,” he said. “Europlacer gives us the throughput and flexibility we need without sacrificing precision.”

Operations Manager Calvin Rabe highlighted the equipment’s intelligent feeders and cross-platform compatibility.

“We can run any part number on any head and move jobs seamlessly between machines,” he said. “That kind of versatility is essential for the variety of components we deal with—01005s to BGAs and everything in between.”

Ryan Kochert, SisTech’s Head of Operations, emphasised the equipment’s scalability. “Europlacer bridges the gap between high-volume production and low-run prototyping. With these machines, we can support runs from two boards to nearly 100,000 units,” he said.