Humanoid robots are coming – and building themselves

With Jabil’s manufacturing experience and Apollo’s design built for mass production, the vision of robots building robots moves closer to reality, paving the way for the mass adoption of humanoid robots.

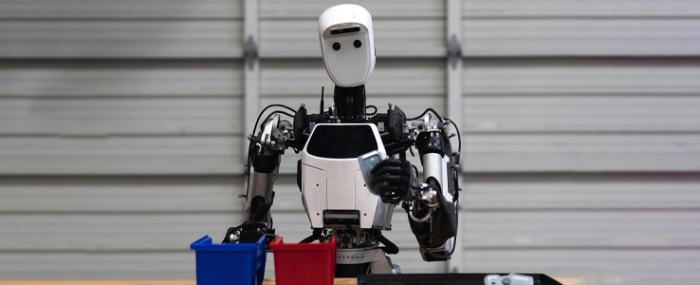

AI-powered humanoid robotics company Apptronik and EMS provider Jabil have launched a pilot program and strategic partnership to build Apollo humanoid robots and deploy them in select Jabil manufacturing facilities. This includes the production lines that will build Apollo humanoid robots, paving the way for "Apollo to build Apollo".

As part of the pilot, newly built Apollo robots will be tested in Jabil’s factories, performing simple, repetitive tasks like inspection, sorting, kitting, and sub-assembly. Once validated, they will be deployed to Apptronik customer site. At Jabil, these robots will support workers by taking over routine tasks, allowing employees to focus on more complex work to enhance future operations.

By building and evaluating the robots function within a production environment, Apptronik and Jabil will gather valuable real-world use cases for automation in manufacturing and optimise Apollo’s AI models.

By partnering with Jabil for large-scale production, Apptronik aims to make general-purpose humanoid robots more accessible for industries like retail, elder care, and, eventually, home use.

Jeff Cardenas, co-founder and CEO of Apptronik, says in a press release that for humanoid robots to become a reality, they need to be able to be built rapidly, at scale – and at the right price point.

“Our partnership with Jabil, along with our unique design for manufacturability and ability to have Apollo humanoid robots handling material movement and assembly tasks in the factory, are critical components needed to create a flywheel effect that could make humanoid robots ubiquitous,” says Jeff Cardenas.

Rafael Renno, Senior Vice President of Global Business Units at Jabil, states that with the company’s commitment to advanced automation and robotics, piloting Apollo is a natural next step for both the division and Jabil’s long-term strategy.

“Not only will we get a first-hand look at the impact that general-purpose robots can have as we test Apollo in our operations, but as we begin producing Apollo units, we can play a role in defining the future of manufacturing. These new technologies and applications further enhance Jabil's best-in-class capabilities to solve complex challenges and manufacture at scale for our customers.”

Humanoid robots to become the next US-China battleground

As reported by market intelligence provider TrendForce, China, Japan, the US, South Korea, and Germany consistently lead in industrial robot installations and are expected to invest over USD 13 billion in related projects by 2025. Governments worldwide are now increasing investments in robotics R&D to address labour shortages and rising costs.

The US and China are pursuing different strategies in humanoid robotics, affecting pricing and application diversity. The US excels in AI development, focusing on smart robotics, autonomous systems, and military applications. Companies like Tesla and Boston Dynamics lead in manufacturing humanoid robots.

In contrast, China emphasises supply chain self-sufficiency and innovation in robotics as outlined in its 14th Five-Year Plan. Chinese humanoid robot manufacturers like Unitree Robotics and UBTECH focus on cost-effective designs and key components for mobility. China's position as the largest battery producer enhances its competitive edge in power efficiency. As these regional strategies evolve, significant price variations and diverse applications in humanoid robots are expected over the next five years.