Electronics Production |

Note UK invests in Siplace technology

Note UK has recently invested significantly in Package on Package (POP) technology in its facility in Stonehouse, Gloucestershire. The result - a Siplace dip flux unit.

Note’s production demands are: high product mix, varying rates of output, a high level of product quality, coupled with meeting the very latest technological requirements, which are successfully handled by a number of Siplace installations - within various Note factories in the Nordic region.

“For Note, this technological challenge means being able to offer “higher technology” services and the ability to compete in the Package on Package (PoP) arena,” comments Dave Westley, Operations Manager for Note UK.

Bearing in mind these technological challenges, when the time came to invest in additional placement capacity, Note contacted the Siplace Team in the UK for advice. Following an in-depth evaluation of Note’s requirements and detailed discussions, the Siplace Team presented a solution to Note which satisfied their wide ranging needs.

Siplace Dip Flux Unit installed at the Siplace D2 Placement Machine

The solution: a Siplace D1 / D2 Placement line. As a result of the new Siplace digital vision system, components and boards are recognized faster, reliably and accurately. Note UK currently operates a single shift pattern, but the requirement is fast set-up and change-over, in addition to competent programming.

Additionally, and in order to be able to provide PoP technology within their service spectrum, Note has also invested in a Siplace dip flux unit for PoP placement. PoP, which is also referred to as CSP-Stacking (Chip Scale Package), is particularly efficient for processor-memory combinations. Allowing to squeeze ever more functions into ever smaller space. It requires less area on the PCB, while benefiting from very short signal paths and less high-frequency interference. To make sure that the upper CSP component of such a “stack” is soldered securely, the solder balls must be coated with flux in a special dip module, before being placed on the lower component.

The Siplace dip flux unit allows a reliable and accurate application of flux material or solder paste (dip media). Smooth surfaces of the dip media are guaranteed, thus resulting in a maximum production yield. Note has developed a process which includes flux depth, alignment and reflow checks to ensure a repeatable and robust fitment process.

Siplace Dip Flux Unit installed at the Siplace D2 Placement Machine

The solution: a Siplace D1 / D2 Placement line. As a result of the new Siplace digital vision system, components and boards are recognized faster, reliably and accurately. Note UK currently operates a single shift pattern, but the requirement is fast set-up and change-over, in addition to competent programming.

Additionally, and in order to be able to provide PoP technology within their service spectrum, Note has also invested in a Siplace dip flux unit for PoP placement. PoP, which is also referred to as CSP-Stacking (Chip Scale Package), is particularly efficient for processor-memory combinations. Allowing to squeeze ever more functions into ever smaller space. It requires less area on the PCB, while benefiting from very short signal paths and less high-frequency interference. To make sure that the upper CSP component of such a “stack” is soldered securely, the solder balls must be coated with flux in a special dip module, before being placed on the lower component.

The Siplace dip flux unit allows a reliable and accurate application of flux material or solder paste (dip media). Smooth surfaces of the dip media are guaranteed, thus resulting in a maximum production yield. Note has developed a process which includes flux depth, alignment and reflow checks to ensure a repeatable and robust fitment process.

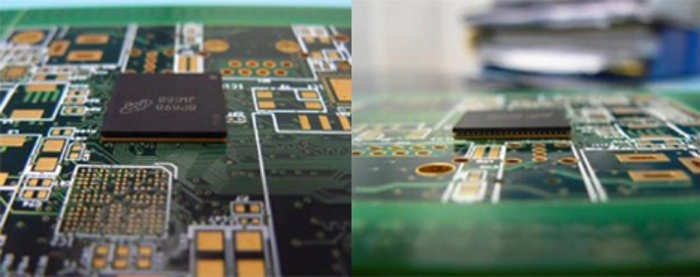

Examples of Post Reflow Assembly

Mr Westley concludes: “Siplace has no doubt made us far more efficient, thus driving down production costs. This not only improves our margin, but enables us to become more competitive in a very cost sensitive market. Additionally, we are able to stay ahead of the competition by offering highly innovative placement processes.”

Examples of Post Reflow Assembly

Mr Westley concludes: “Siplace has no doubt made us far more efficient, thus driving down production costs. This not only improves our margin, but enables us to become more competitive in a very cost sensitive market. Additionally, we are able to stay ahead of the competition by offering highly innovative placement processes.”

Siplace Dip Flux Unit installed at the Siplace D2 Placement Machine

The solution: a Siplace D1 / D2 Placement line. As a result of the new Siplace digital vision system, components and boards are recognized faster, reliably and accurately. Note UK currently operates a single shift pattern, but the requirement is fast set-up and change-over, in addition to competent programming.

Additionally, and in order to be able to provide PoP technology within their service spectrum, Note has also invested in a Siplace dip flux unit for PoP placement. PoP, which is also referred to as CSP-Stacking (Chip Scale Package), is particularly efficient for processor-memory combinations. Allowing to squeeze ever more functions into ever smaller space. It requires less area on the PCB, while benefiting from very short signal paths and less high-frequency interference. To make sure that the upper CSP component of such a “stack” is soldered securely, the solder balls must be coated with flux in a special dip module, before being placed on the lower component.

The Siplace dip flux unit allows a reliable and accurate application of flux material or solder paste (dip media). Smooth surfaces of the dip media are guaranteed, thus resulting in a maximum production yield. Note has developed a process which includes flux depth, alignment and reflow checks to ensure a repeatable and robust fitment process.

Siplace Dip Flux Unit installed at the Siplace D2 Placement Machine

The solution: a Siplace D1 / D2 Placement line. As a result of the new Siplace digital vision system, components and boards are recognized faster, reliably and accurately. Note UK currently operates a single shift pattern, but the requirement is fast set-up and change-over, in addition to competent programming.

Additionally, and in order to be able to provide PoP technology within their service spectrum, Note has also invested in a Siplace dip flux unit for PoP placement. PoP, which is also referred to as CSP-Stacking (Chip Scale Package), is particularly efficient for processor-memory combinations. Allowing to squeeze ever more functions into ever smaller space. It requires less area on the PCB, while benefiting from very short signal paths and less high-frequency interference. To make sure that the upper CSP component of such a “stack” is soldered securely, the solder balls must be coated with flux in a special dip module, before being placed on the lower component.

The Siplace dip flux unit allows a reliable and accurate application of flux material or solder paste (dip media). Smooth surfaces of the dip media are guaranteed, thus resulting in a maximum production yield. Note has developed a process which includes flux depth, alignment and reflow checks to ensure a repeatable and robust fitment process.

Examples of Post Reflow Assembly

Mr Westley concludes: “Siplace has no doubt made us far more efficient, thus driving down production costs. This not only improves our margin, but enables us to become more competitive in a very cost sensitive market. Additionally, we are able to stay ahead of the competition by offering highly innovative placement processes.”

Examples of Post Reflow Assembly

Mr Westley concludes: “Siplace has no doubt made us far more efficient, thus driving down production costs. This not only improves our margin, but enables us to become more competitive in a very cost sensitive market. Additionally, we are able to stay ahead of the competition by offering highly innovative placement processes.”