Seamless Integration and Open Architecture: ENTE’s Success Story with Cogiscan in SMT Manufacturing

Introduction:

ENTE, an electronics engineering company specializing in the manufacturing of modern electronics products for transportation and localization/monitoring, primarily in railway, automotive, and public transit, also extends their services by building Printed Circuit Board Assemblies (PCBAs) for other companies in various industries.

ENTE focuses on low to mid-volume manufacturing at their facility in Poland, and as a technology forward company they are always looking for ways to optimize their manufacturing operation. ENTE kick started this journey in 2007 through a long-term and strategic collaboration with SMT specialists, PB Technik Sp. z o.o. With the procurement of both new equipment and software systems through PB Technik, ENTE has dramatically improved their overall production process and throughput.

Background & Challenges

ENTE operates three Surface Mount Technology (SMT) lines, utilizing a range of equipment provided by PB Technik, including Pick & Place (P&P) machines, reflow ovens, AOI, SPI, X-ray for components inspection and X-ray component counter, wave soldering, and more. Until 2020, ENTE relied on a basic traceability system for data tracking and reporting. That year, ENTE decided to both update and expand their traceability system with the new JUKI machines they had purchased. Due to internal traceability system limitations they were unable to expand, therefore they took advantage of PB Technik’s offer which persuaded them of the key benefits they would gain from implementing the Cogiscan's 360° traceability system.

Original Solution:

As soon as ENTE decided to adopt Cogiscan's traceability system, it became clear that the type of material, process, and product data available within this new system provided greater detail than what they were collecting previously. Additionally, ENTE saw tremendous benefit in adding Cogiscan’s Open Interface to seamlessly connect the data streams from their existing traceability system with Cogiscan’s data and reporting – thus enhancing the granularity and accuracy of ENTE’s final traceability report. The integration process was simple, facilitated by ENTE's high-tech orientation and self-sufficiency in IT capabilities. Cogiscan’s open architecture allows for synchronous transaction-based communication, while maintaining seamless accessibility and real-time sharing of factory data.

Further Implementation:

After the installation, ENTE was impressed by both the accuracy and richness of the data Cogiscan’s system provided. They expanded their integration by connecting an X-ray component counter to Cogiscan, further improving their material management efforts by automatically updating material quantities. This addition helped to further increase the ROI of their investment in Cogiscan’s software.

Customization and Adaptation:

As a modern and tech-savvy company, ENTE was able to leverage the openness of Cogiscan’s underlying system architecture. They independently established connections between both systems and adapted their internal "PDA" device. For ENTE it was imperative that the Cogiscan system accepts raw material labels with unique identification number designed by them.

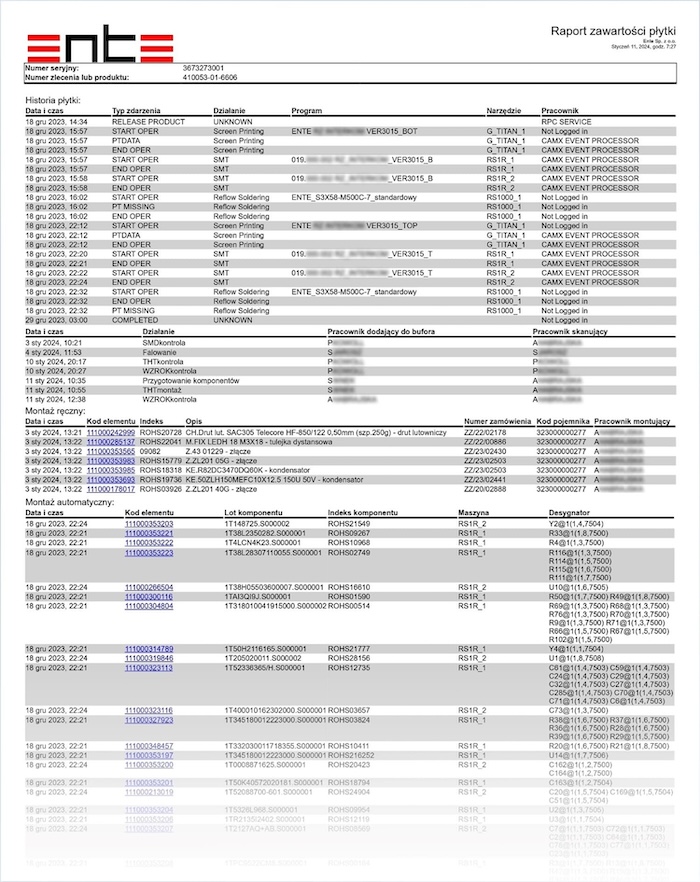

Furthermore, they translated all reporting into Polish in order to create customized reports, with ENTE’s logo embedded, for their end-customers. Cogiscan’s system flexibility allows ENTE to easily create and share robust traceability reports with their customers. In fact, many of their customers now depend on these traceability reports and appreciate ENTE’s committed efforts towards transparent collaboration.

Results:

The successful integration of Cogiscan’s software into ENTE's manufacturing process significantly improved both their traceability and material management efforts. Due to material and process parameters tracking, ENTE stores full information about every raw material used in production as well as its purchase history. This enables ENTE to increase the quality of their service, and also provides faster access to information about all the components used in various projects.

Since implementing the Cogiscan system, ENTE has received more opportunities for interesting projects from demanding sectors like aerospace and automotive. For these companies, full traceability is crucial and the Cogiscan traceability system fully meets these needs.

"The involvement of ENTE specialists in the integration of the Cogiscan system has also resulted in offering a wider range of services. In addition to the already advanced quality control at each stage of the process, we can now provide the customer with a full and detailed traceability system report," commented Jacek Zając, ENTE Production Manager.

Strong Partnership:

ENTE and PB Technik continue to maintain a positive, trusting, and long-term relationship. Grzegorz Andryszczak, Technical Director at PB Technik, commented, “We are pleased to be able to offer our customers s Cogiscan’s software to improve the quality of their services. We care about the satisfaction and development of our customers, and thanks to ENTE specialists, the potential of this system has been fully realized.”

ENTE now stands as the preferred reference account for PB Technik’s potential customers interested in investing in high-tech SMT equipment like JUKI machinery and Cogiscan’s traceability.

Conclusion:

The integration between ENTE and Cogiscan highlights the transformative impact of adopting advanced traceability systems in SMT production. The modular nature of Cogiscan’s system allowed ENTE to custom tailor their traceability program to suit their specific needs – instead of having to replace their in-house traceability system, ENTE leveraged Cogiscan’s open interface to complement and improve upon what they already had built. ENTE's proactive approach to technology adoption, combined with the capabilities of Cogiscan’s accessible architecture, has resulted in enhanced accuracy, more detailed data collection, and optimized material and process management, contributing to the overall efficiency of ENTE’s manufacturing processes.