Sponsored content by Cogiscan

Component Shortage: Stock is King

Since the shortage is here to stay, what can you do to maximize the precious components you’ve finally managed to get your hands on?

Allocation. One of most used (and hated) words of 2021. People can say whatever they want, it’s not just an SMT manufacturing problem anymore. People outside of our industry are also experiencing the headaches associated with component shortages – even Apple had to delay releasing their newest iPhone by a few months. We’ve all heard a story or two about someone waiting months and months for a new car or dishwasher.

Take a look around you. Pretty much everything you see has a circuit board in it. Whether they’re powering phones, computers, cars or simply the car key, manufacturers are all competing against each other for the same components, which explains the current situation. And while manufacturers are competing against each other, all fighting for the same parts to deliver their products, experts now expect the situation to continue well in 2022.

What can you do?

Option #1: Rethinking the Supply Chain

Allocation. One of most used (and hated) words of 2021. People can say whatever they want, it’s not just an SMT manufacturing problem anymore. People outside of our industry are also experiencing the headaches associated with component shortages – even Apple had to delay releasing their newest iPhone by a few months. We’ve all heard a story or two about someone waiting months and months for a new car or dishwasher.

Take a look around you. Pretty much everything you see has a circuit board in it. Whether they’re powering phones, computers, cars or simply the car key, manufacturers are all competing against each other for the same components, which explains the current situation. And while manufacturers are competing against each other, all fighting for the same parts to deliver their products, experts now expect the situation to continue well in 2022.

What can you do?

Option #1: Rethinking the Supply Chain

Many companies are currently rethinking how supply chains are working – offering solutions related to real-time visibility, improved production capacity, and realistic forecasted demand. And while all of this will eventually help get us out of the hole, these are longer term solutions. What can you do today?

Option #2: Maximizing Your Components

Many companies are currently rethinking how supply chains are working – offering solutions related to real-time visibility, improved production capacity, and realistic forecasted demand. And while all of this will eventually help get us out of the hole, these are longer term solutions. What can you do today?

Option #2: Maximizing Your Components

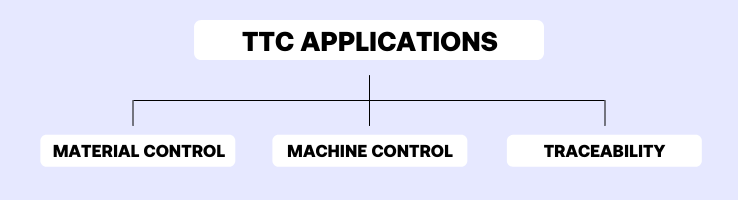

Another option would be to maximize the utilization and quality of the components you’re able to get into your factory. In other words, how can you get the most value out of every single IC in your inventory? Well, Track, Trace & Control (TTC) solutions have been used in the industry for decades and have already helped thousands of factories improve their performance. These solutions are about helping you quickly locate and use your materials while also making sure that everything is tracked throughout the manufacturing process. TTC solutions can be divided into three subcategories: Material Control, Machine Control and Traceability.

Another option would be to maximize the utilization and quality of the components you’re able to get into your factory. In other words, how can you get the most value out of every single IC in your inventory? Well, Track, Trace & Control (TTC) solutions have been used in the industry for decades and have already helped thousands of factories improve their performance. These solutions are about helping you quickly locate and use your materials while also making sure that everything is tracked throughout the manufacturing process. TTC solutions can be divided into three subcategories: Material Control, Machine Control and Traceability.

Material Control

We’ve said it before and we’ll say it again (and again): In today’s reality, keeping track of all your components should be your main priority. Why? No one has the freedom to waste components anymore. With an industry-specific Inventory Management solution, you’ll never lose a component again – whether they are set up on a trolley waiting for the next job or sitting in a bin next to a repair station – you’ll have visibility to their precise location.

To help make up for lost time or to fulfill backorders, you might be thinking about buying new equipment. Even though this might seem viable, those new machines will face the same problem: a lack of components… Instead of buying new equipment, perhaps it’s as simple as optimizing the utilization of your current machines?

Material Control

We’ve said it before and we’ll say it again (and again): In today’s reality, keeping track of all your components should be your main priority. Why? No one has the freedom to waste components anymore. With an industry-specific Inventory Management solution, you’ll never lose a component again – whether they are set up on a trolley waiting for the next job or sitting in a bin next to a repair station – you’ll have visibility to their precise location.

To help make up for lost time or to fulfill backorders, you might be thinking about buying new equipment. Even though this might seem viable, those new machines will face the same problem: a lack of components… Instead of buying new equipment, perhaps it’s as simple as optimizing the utilization of your current machines?

Machine Control

Have you ever had to scrap and waste some of your ICs because your machine was running the wrong program or because it was simply out of spec? Most certainly… and that indicates that there’s room for improvement. With a software that validates everything PRIOR to a job, you can be assured that your manufacturing process is running exactly as it should – with the right programs loaded for the correct product, the right materials set-up in the right locations, and the right machine settings and process parameters in place. That’s one less thing to worry about.

Counterfeit components aren’t new in our industry. However, you should stay alert because we’ve seen an increase in their popularity since the beginning of this shortage. Even though there are numerous ways to prevent fake components from getting used in a factory, some of them might still find their way onto your boards. What should you do if that happens?

Machine Control

Have you ever had to scrap and waste some of your ICs because your machine was running the wrong program or because it was simply out of spec? Most certainly… and that indicates that there’s room for improvement. With a software that validates everything PRIOR to a job, you can be assured that your manufacturing process is running exactly as it should – with the right programs loaded for the correct product, the right materials set-up in the right locations, and the right machine settings and process parameters in place. That’s one less thing to worry about.

Counterfeit components aren’t new in our industry. However, you should stay alert because we’ve seen an increase in their popularity since the beginning of this shortage. Even though there are numerous ways to prevent fake components from getting used in a factory, some of them might still find their way onto your boards. What should you do if that happens?

Traceability

Worst-case scenario: you’re toward the end of the production run and you find out that some of your stock is contaminated with fake components. What should you do? The first thing you need to do is to quickly identify and locate which of your PCBs have been affected by the problem to avoid a recall, or at least minimize its impact. Having the right traceability solution will not only save you time and money, but it will also help you maintain your reputation and we all know that in our industry, it takes years to build one, but seconds to destroy it…

What to expect in years to come?

While many of us wish the component shortage would resolve overnight, the fact remains that we’ll likely still be dealing with it this time next year. In the meantime, you’ve got to make the best of what you have by protecting your precious resources and maximizing your equipment utilization. Where should you start? By chatting with an expert on cogiscan.com.

Traceability

Worst-case scenario: you’re toward the end of the production run and you find out that some of your stock is contaminated with fake components. What should you do? The first thing you need to do is to quickly identify and locate which of your PCBs have been affected by the problem to avoid a recall, or at least minimize its impact. Having the right traceability solution will not only save you time and money, but it will also help you maintain your reputation and we all know that in our industry, it takes years to build one, but seconds to destroy it…

What to expect in years to come?

While many of us wish the component shortage would resolve overnight, the fact remains that we’ll likely still be dealing with it this time next year. In the meantime, you’ve got to make the best of what you have by protecting your precious resources and maximizing your equipment utilization. Where should you start? By chatting with an expert on cogiscan.com.