Sponsored content by Electrolube

A New Generation of Conformal Coatings for Challenging Operating Environments

Electrolube’s Phil Kinner discusses the evolution of tougher, more environmentally friendly conformal coating materials that have been formulated to cope reliably with the rigours of modern electronics deployments

Modern electronic assemblies are increasingly expected to survive hostile operating environments and work reliably in conditions of prolonged high temperatures in the presence of thermal shock and high humidity, and where the assembly may be subject to condensation, corrosive agents or other types of chemical attack. Despite this, weight-saving measures have reduced the robustness – and therefore the protective properties - of enclosures and at the same time, environmental legislation continues to limit the use of those considerably more versatile solvent-based protective materials.

A conformal coating provides that essential secondary line of defence beyond that of the enclosure, so in order to achieve long service life for an assembly deployed in a harsh operating environment, it is useful to consider the common modes of attack and, ultimately, how they may be tackled. When selecting a suitable conformal coating material for harsh environments, the following issues must be addressed: the potential for corrosion and condensing conditions and/or immersion in water, component spacing and tin whisker formation.

Corrosion

Corrosion is a complicated, diffusion controlled, electro-chemical process that takes place on an exposed metal surface. Despite the range of potential mechanisms and causes, in the majority of cases, three requirements must be met in order for corrosion to take place: the presence of intrinsically electrochemically dissimilar metals (e.g. Gold/Silver and Nickel/Tin), or the creation of an anode and cathode by application of applied bias; the presence of an ionic species (salts, halides, hydroxides and so on); and the presence of mono-layers of condensed water to dissolve the ionic species, producing an electrolyte solution. Preventing corrosion involves the removal of at least one of these pre-requisite conditions.

Choice of metals is limited to those used in the solder and solder finish chemistries (which are dissimilar), and there will always be areas of potential difference due to the nature of an electronic assembly. Cleaning can help remove ionic species, but cannot prevent their re-deposition from the operating environment.

Conformal Coatings help prevent the formation of electrolytic solutions by acting as moisture barriers. All metal surfaces on a PCB need to be sufficiently well coated to prevent exposure to a potentially corrosive environment; even small voids in the coating that expose the metal surface can actually accelerate corrosion under certain environmental conditions. The conformal coating challenge is to achieve an appropriate level of coverage of all exposed metal surfaces across the three-dimensional, complex topography that defines the modern PCB.

In addition to this ‘perfect’ coverage, the coating also needs to provide a barrier against moisture while achieving good adhesion to the substrate to prevent delamination. Once a coating is delaminated, moisture ingress will occur, ultimately producing an electrolytic solution from contact with any pre-existing ionic contamination – another very good reason for thoroughly cleaning the board prior to conformal coating application.

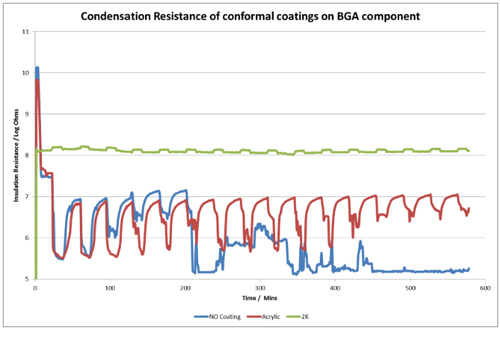

Condensation

Where there is a significant level of humidity, certain areas of an assembly may drop below the dew point and water will condense on the PCB surfaces, significantly reducing insulation resistance. While pure water is not a particularly good conductor of electricity, any ionic impurities present on the PCB surface will become solubilised to form a conductive pathway. As well as leading to corrosion as described above, these conditions will severely test the insulation resistance of the coating.

Component spacing

Although air is normally an excellent insulator, it can break down in the presence of an electric field greater than 3kV/mm and become partially conductive. Breakdown voltage in air will depend upon the separation of components populating the PCB. If the potential difference between adjacent components is sufficiently high, a complete electrical breakdown in air will culminate in an electric arc that bridges the entire gap between the components. Conformal coatings provide additional insulation resistance and designers can use them to achieve more compact assemblies by placing components closer together than would otherwise be possible without a coating.

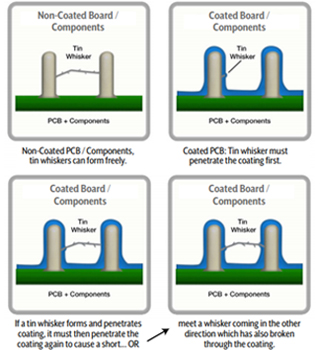

Tin whisker formation

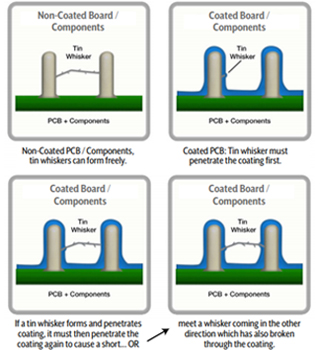

Conformal coatings can also be used to prevent problems posed by tin whisker formation which can lead to localised short circuits. Although current research has shown it to be unlikely, a tin whisker eruption needs to puncture and penetrate out through the coating. And in order to produce a short circuit, the protruding tin whisker must either meet another protruding tin whisker from an alternative polarity or penetrate back through the coating to a place of opposite polarity.

The two-component approach

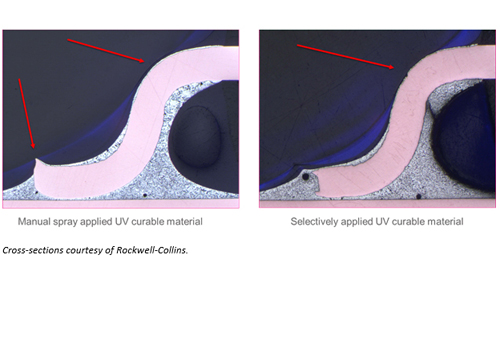

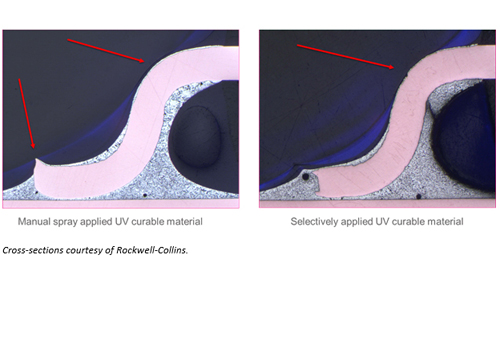

For conventional liquid-applied materials and application processes, achieving good coverage and thickness has been shown to be problematic. For example, in a recent IPC ‘state of the industry assessment’, which contained an analysis of literally thousands of cross-sections, it was reported that little or no coverage was obtained on many common component leads and bodies for all material/process combinations. Given the importance of edge-coverage and thickness, and the need to achieve both while still maintaining other performance requirements, such as thermal shock resistance and tolerance of thermal cycling, a new coating concept was developed to meet these challenges.

Tin whisker formation

Conformal coatings can also be used to prevent problems posed by tin whisker formation which can lead to localised short circuits. Although current research has shown it to be unlikely, a tin whisker eruption needs to puncture and penetrate out through the coating. And in order to produce a short circuit, the protruding tin whisker must either meet another protruding tin whisker from an alternative polarity or penetrate back through the coating to a place of opposite polarity.

The two-component approach

For conventional liquid-applied materials and application processes, achieving good coverage and thickness has been shown to be problematic. For example, in a recent IPC ‘state of the industry assessment’, which contained an analysis of literally thousands of cross-sections, it was reported that little or no coverage was obtained on many common component leads and bodies for all material/process combinations. Given the importance of edge-coverage and thickness, and the need to achieve both while still maintaining other performance requirements, such as thermal shock resistance and tolerance of thermal cycling, a new coating concept was developed to meet these challenges.

Electrolube developed its 2K conformal coatings series to provide the solution. The high performance ‘2K’ two-part conformal coatings series offers capacity for greater coating thickness and enhanced edge coverage while being VOC-free, fast-curing and a more economical, solvent-free alternative to silicone materials.

Electrolube developed its 2K conformal coatings series to provide the solution. The high performance ‘2K’ two-part conformal coatings series offers capacity for greater coating thickness and enhanced edge coverage while being VOC-free, fast-curing and a more economical, solvent-free alternative to silicone materials.

Solvent-free

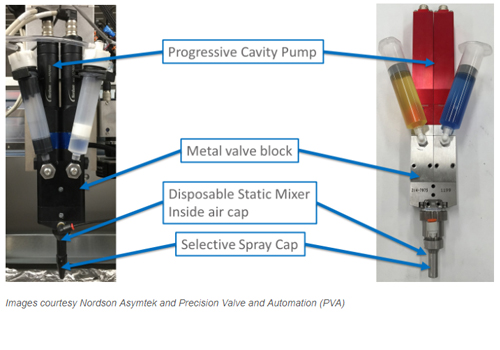

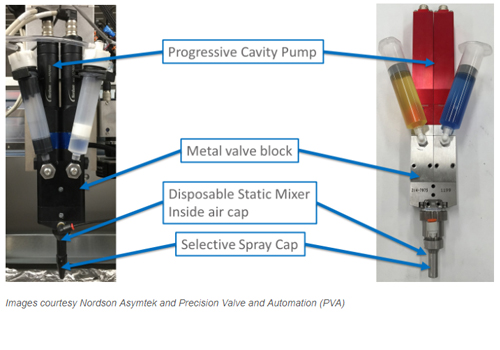

Electrolube’s move to a solvent-free 2K system required a new approach to mixing and delivery. With coating applications, controlling the flow rate at a suitably low level whilst also maintaining the correct mix ratios, was the key challenge and has recently been overcome by the use of specially developed, low volume progressive cavity pumps. Additionally, the spray head velocity can be up to three times faster than traditional 100% solids materials spray applications, significantly reducing coating cycle times.

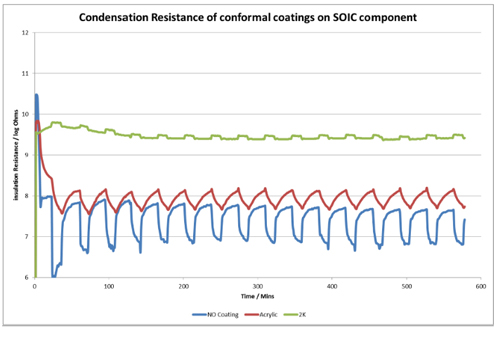

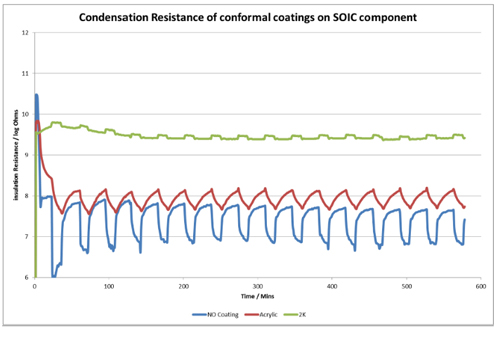

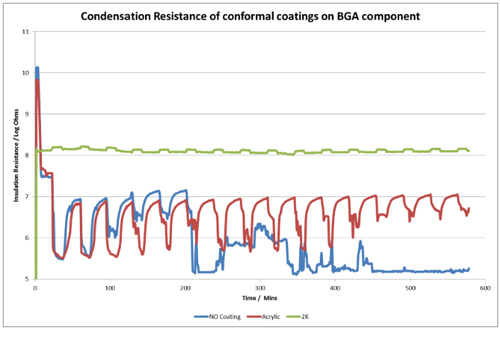

In rigorous testing, these new two part systems demonstrate very impressive performance when compared with other coating types.

Solvent-free

Electrolube’s move to a solvent-free 2K system required a new approach to mixing and delivery. With coating applications, controlling the flow rate at a suitably low level whilst also maintaining the correct mix ratios, was the key challenge and has recently been overcome by the use of specially developed, low volume progressive cavity pumps. Additionally, the spray head velocity can be up to three times faster than traditional 100% solids materials spray applications, significantly reducing coating cycle times.

In rigorous testing, these new two part systems demonstrate very impressive performance when compared with other coating types.

To Read the full length of this article and more details about the test results, visit Electrolube.com

To Read the full length of this article and more details about the test results, visit Electrolube.com

Tin whisker formation

Conformal coatings can also be used to prevent problems posed by tin whisker formation which can lead to localised short circuits. Although current research has shown it to be unlikely, a tin whisker eruption needs to puncture and penetrate out through the coating. And in order to produce a short circuit, the protruding tin whisker must either meet another protruding tin whisker from an alternative polarity or penetrate back through the coating to a place of opposite polarity.

The two-component approach

For conventional liquid-applied materials and application processes, achieving good coverage and thickness has been shown to be problematic. For example, in a recent IPC ‘state of the industry assessment’, which contained an analysis of literally thousands of cross-sections, it was reported that little or no coverage was obtained on many common component leads and bodies for all material/process combinations. Given the importance of edge-coverage and thickness, and the need to achieve both while still maintaining other performance requirements, such as thermal shock resistance and tolerance of thermal cycling, a new coating concept was developed to meet these challenges.

Tin whisker formation

Conformal coatings can also be used to prevent problems posed by tin whisker formation which can lead to localised short circuits. Although current research has shown it to be unlikely, a tin whisker eruption needs to puncture and penetrate out through the coating. And in order to produce a short circuit, the protruding tin whisker must either meet another protruding tin whisker from an alternative polarity or penetrate back through the coating to a place of opposite polarity.

The two-component approach

For conventional liquid-applied materials and application processes, achieving good coverage and thickness has been shown to be problematic. For example, in a recent IPC ‘state of the industry assessment’, which contained an analysis of literally thousands of cross-sections, it was reported that little or no coverage was obtained on many common component leads and bodies for all material/process combinations. Given the importance of edge-coverage and thickness, and the need to achieve both while still maintaining other performance requirements, such as thermal shock resistance and tolerance of thermal cycling, a new coating concept was developed to meet these challenges.

Electrolube developed its 2K conformal coatings series to provide the solution. The high performance ‘2K’ two-part conformal coatings series offers capacity for greater coating thickness and enhanced edge coverage while being VOC-free, fast-curing and a more economical, solvent-free alternative to silicone materials.

Electrolube developed its 2K conformal coatings series to provide the solution. The high performance ‘2K’ two-part conformal coatings series offers capacity for greater coating thickness and enhanced edge coverage while being VOC-free, fast-curing and a more economical, solvent-free alternative to silicone materials.

Solvent-free

Electrolube’s move to a solvent-free 2K system required a new approach to mixing and delivery. With coating applications, controlling the flow rate at a suitably low level whilst also maintaining the correct mix ratios, was the key challenge and has recently been overcome by the use of specially developed, low volume progressive cavity pumps. Additionally, the spray head velocity can be up to three times faster than traditional 100% solids materials spray applications, significantly reducing coating cycle times.

In rigorous testing, these new two part systems demonstrate very impressive performance when compared with other coating types.

Solvent-free

Electrolube’s move to a solvent-free 2K system required a new approach to mixing and delivery. With coating applications, controlling the flow rate at a suitably low level whilst also maintaining the correct mix ratios, was the key challenge and has recently been overcome by the use of specially developed, low volume progressive cavity pumps. Additionally, the spray head velocity can be up to three times faster than traditional 100% solids materials spray applications, significantly reducing coating cycle times.

In rigorous testing, these new two part systems demonstrate very impressive performance when compared with other coating types.

To Read the full length of this article and more details about the test results, visit Electrolube.com

To Read the full length of this article and more details about the test results, visit Electrolube.com