Sponsored content by CML EurAsia

Stay cool with CML PCBs

Electronics are designed and built to be sustainable, but where there is light there must be shadow and this shadow is called "heat" in electronics.

So how can we reduce the thermal stress on components to secure the safety and reliability of electronics?

In order to prevent the components from overheating, it is necessary to get rid of unwanted heat and cool them down. Thermal management is key for high powered components which generate a lot of heat such as: LED applications, voltage regulators or electronic motor controls.

One option of thermal management is to assemble a heat sink directly on components to absorb excessive heat. Overall, this procedure would mean additional effort during assembly.

Alternatively the PCB itself can be a cooling solution, for example by using laminates with high thermal conductivity (1-5 W/mK compared to 0,3 W/mK on standard FR4).

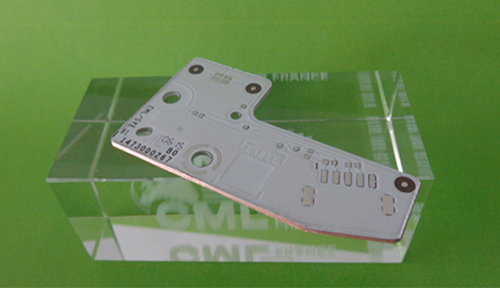

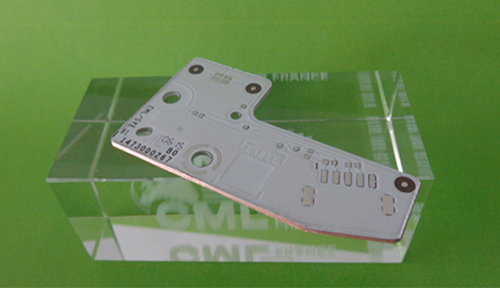

Therefore CML offers various solutions for your specific requirements:

• Aluminum substrate

• Copper substrate

• Flex on Aluminium or Copper

• Post bonded heatsinks

• Copper inlay (Inlay-/Coin-Technology)

• Aluminium nitride inlay

• Thermal vias / microvias (drilled / lasered)

• “Heavy” copper

To find out which solution is the most suitable for your project, get in touch with us today,marketing@cml.ag

About CML

CML are the leaders in printed circuit board (PCB) sourcing solutions. CML’s mission “We care about reliable connections,” places paramount importance on the relationship between all stakeholders from customers to suppliers to the CML Team. These reliable connections deliver convenience and reliability, provides a wide product portfolio and an umbrella of services ranging from consultancy, design, engineering, manufacturing and logistics for all markets. CML has a global network, located across 13 international cities and a local presence with a multilingual and culturally diverse team. For more information please visit our website: http://www.cml-globalsolutions.com

To find out which solution is the most suitable for your project, get in touch with us today,marketing@cml.ag

About CML

CML are the leaders in printed circuit board (PCB) sourcing solutions. CML’s mission “We care about reliable connections,” places paramount importance on the relationship between all stakeholders from customers to suppliers to the CML Team. These reliable connections deliver convenience and reliability, provides a wide product portfolio and an umbrella of services ranging from consultancy, design, engineering, manufacturing and logistics for all markets. CML has a global network, located across 13 international cities and a local presence with a multilingual and culturally diverse team. For more information please visit our website: http://www.cml-globalsolutions.com

To find out which solution is the most suitable for your project, get in touch with us today,marketing@cml.ag

About CML

CML are the leaders in printed circuit board (PCB) sourcing solutions. CML’s mission “We care about reliable connections,” places paramount importance on the relationship between all stakeholders from customers to suppliers to the CML Team. These reliable connections deliver convenience and reliability, provides a wide product portfolio and an umbrella of services ranging from consultancy, design, engineering, manufacturing and logistics for all markets. CML has a global network, located across 13 international cities and a local presence with a multilingual and culturally diverse team. For more information please visit our website: http://www.cml-globalsolutions.com

To find out which solution is the most suitable for your project, get in touch with us today,marketing@cml.ag

About CML

CML are the leaders in printed circuit board (PCB) sourcing solutions. CML’s mission “We care about reliable connections,” places paramount importance on the relationship between all stakeholders from customers to suppliers to the CML Team. These reliable connections deliver convenience and reliability, provides a wide product portfolio and an umbrella of services ranging from consultancy, design, engineering, manufacturing and logistics for all markets. CML has a global network, located across 13 international cities and a local presence with a multilingual and culturally diverse team. For more information please visit our website: http://www.cml-globalsolutions.com