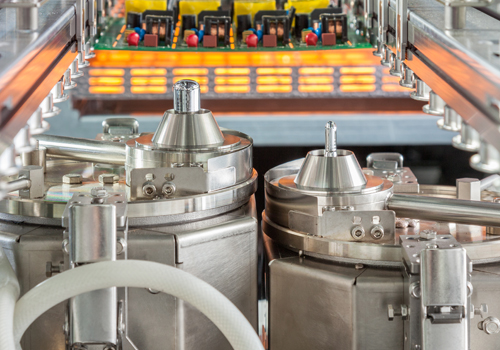

Future-proof with modern Ersa selective soldering technology

The classic soldering process for THT components is the wave soldering process. However, more and more electronics manufacturers are coming up against limits imposed by the assembly’s design. Today, selective soldering is the first choice and offers many advantages compared to wave soldering. With selective soldering, the overall heat input into the assembly is significantly lower, and solder masks are not required. Due to the individual selection of soldering parameters per solder joint, the selective soldering process is characterized by highest quality and reproducibility.

> More about Selective Soldering Technology

No solder masks required in selective soldering

In wave soldering, solder masks protect SMD components located on the underside of the circuit board from re-melting and being washed away when touched by the solder wave. Solder masks are required even for very small production lots, and they must be specifically designed and manufactured for each product. This is both a time and cost factor. Advantage Selective Soldering!

Flexibility in the selective soldering process

Another selective soldering bonus: It is possible to solder individual components of a board with individual parameters, whereas with wave soldering one has to make the compromise of having to select temperature and the wetting time in the solder wave for the entire assembly. It is then necessary to find the best average value to protect sensitive components and still achieve sufficient solder wetting of those connections with high heat requirements. At the same time, contamination of the assembly is lower with selective soldering, since only the few areas to be soldered come into contact with flux and solder.

The selective fluxing system must meet several requirements at the same time: In addition to precision and speed, high-quality fluxing processes require a high degree of reliability. The areas of the PCB which are not wetted by the solder wave may also not be exposed to flux.

> More about Ersa Selective Soldering Systems

Economic advantages

The advantages of wave or selective soldering processes are to be found in the design of the assemblies to be processed. For assemblies with mixed SMT and THT components, the classic wave soldering system has a clear advantage if the SMDs are located only on the top side of the PCB. In this case, the wave soldering process is very economical because solder masks are not required for processing. If, on the other hand, the underside of the PCB is also fitted with SMDs (with a low proportion of THT components), selective soldering has an advantage, as the economic efficiency is significantly higher simply because solder masks are no longer required, and consumables (flux, solder and nitrogen) are saved.

The mini-wave soldering module can optionally be equipped with two solder pots. Subject to the user´s requirements they can then be equipped with two different solder nozzles and solder alloys. Or one uses two identical solder nozzles for the soldering of PCB panels. The solder module is preceded by the preheating process, which heats the assemblies homogeneously in order to reduce the thermal stress during subsequent contact with the liquid solder.

Equipped for the future – with leading technology and proven standard processes

Ersa offers selective soldering systems for every need and every budget. Starting with the VERSAFLOW ONE, the new entry-level model for demanding high-end selective soldering, to its bigger sibling, the VERSAFLOW 3/45 platform, which is in use more than 2,000 times worldwide, to the extremely flexible VERSAFLOW 4/55 series – all Ersa inline selective soldering systems offer strong features, modular design and the excellent quality and services of the world market leader. Regardless of which system is chosen, the core processes of fluxing, preheating and soldering are based on the same functional modules with a wide range of automatic process monitoring in all systems. Regardless of the machine chosen, the user thus has standard processes for the production of his product spectrum at his disposal, which have proven themselves efficiently and sustainably thousands of times in worldwide electronics production and which are also compatible for future requirements.

With top technology and modular design, Ersa meets the highest demands for flexibility and throughput. Thousands of Ersa selective soldering systems have been installed worldwide and stand for variety, quality and safety. VERSAFLOW ONE, the youngest member of the Ersa VERSAFLOW family, marks the entry into the excellence class of inline selective soldering. THE ONE. FOR EVERYONE.

> The complete Electronics Production Equipment Portfolio

> More about the extensive range of trainings for electronics production