Nexperia boost production with Essemtec Fox MFC from Altus

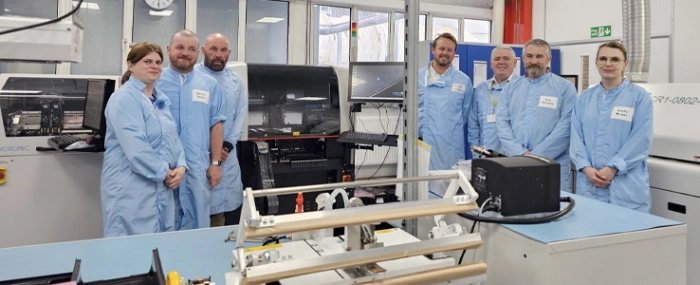

Altus Group says that it has successfully implemented the Essemtec Fox MFC Pick and Place system at Nexperia's Stockport facility.

This system has enhanced Nexperia's SMT production capabilities, addressing their need for increased flexibility and future-proofing. Nexperia selected the Essemtec Fox MFC following a comprehensive market review. The system's integrated concept, capable of both component placement and dispensing of epoxy and solder paste, was a key factor in their decision.

"We were really drawn to the all-in-one concept to future-proof our needs, which is very unique. The machine is very flexible and versatile and is packed with features and capability when you compare it to other solutions in the market," says Rob Horsley, Nexperia Senior Surface Mount Engineer, in a press release.

The Essemtec Fox MFC offers several advanced features that align with Nexperia's production requirements. Its compact footprint is ideal for space-constrained environments, while its modular design supports up to 120 feeder lanes (180 as a batch). The system also includes integrated 2D defect detection for precise, high-quality production, and quick changeover capabilities enabling non-stop production. With a high productivity of up to 12,000 components per hour per module, the Fox MFC significantly boosts manufacturing efficiency.

"It has been great to see how the project with Nexperia has worked out and to get another satisfied Essemtec user in the UK and Ireland. The team at Nexperia had a refreshing approach to the machine selection, and it was a pleasure to support them and show what we can do," adds Charles Lower, Altus Sales Manager, in the press release.

The implementation of the Essemtec Fox MFC has optimised Nexperia's production efficiency and flexibility. "We are really happy with the machine and the support that we have had from Altus and Essemtec throughout," said Rob.