How to inspect chip for counterfeits

Several inspection methods can help to identify counterfeit, or signal that a deeper inspection level is required. Systems design software provider Cadence has taken a deep dive into this subject.

According to Cadence blog, it seems that every time there is a component shortage, the issues of brokers hoarding components and distributing counterfeits become major problems again. Counterfeit components are not a new problem, but counterfeits combined with hoarding of components by brokers create a perfect storm of risk for OEMs and EMS companies. When companies get desperate for parts and start looking to non-authorized distributors, they put themselves at risk of procuring fake parts.

Therefore according to Cadence, it’s important for companies to know what steps they can take to:

- Identify fake components in a parts kit

- Identify reputable brokers if needed

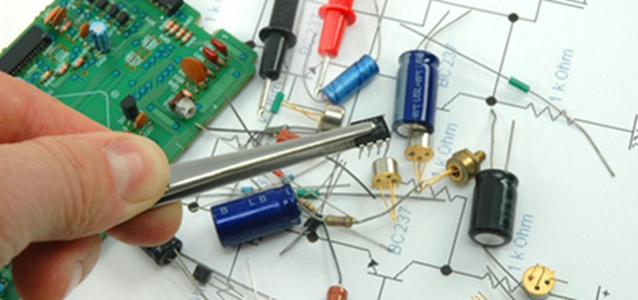

Inspection of components involves looking at the packaging, as well as internally with destructive or non-destructive methods. There are also testing methods that can be used to determine whether parts are genuine as described in product literature and documentation.

Counterfeit Component Inspection Methods

Some of the most common attempts at counterfeiting do not involve forging components. Instead they involve misrepresenting a component. This can involve one or more of the following:

- Removing the part number from a component

- Replacing the part number with a different part number

- Modifying the part number so that the part appears to be a more expensive variant

- Sending the correct component, but the part was used and pulled from an old assembly

- Removing the die from a component