Why AMR sensors are a great option for high precision position measurements

Question: What is the best type of sensor to measure the position of moving and rotating elements?

Benjamin Reiss, Field Applications Engineer

Answer: Try an anisotropic magnetoresistive (AMR) sensor, such as the ADA4570.

Nowadays, there are many different ways to measure the position of moving and rotating elements. Apart from optical encoders, Hall sensors, and resolvers, magnetic sensors based on the magnetoresistive effect are used. There is a giant magnetoresistive (GMR) and a tunnel magnetoresistive (TMR) effect as well as an anisotropic magnetoresistive (AMR) effect, which this article delves further into.

The ADA4570 AMR sensor from Analog Devices makes use of the characteristic of ferromagnetic materials in which the electrical resistance depends on the direction of magnetization—a phenomenon that was discovered by William Thomson (Lord Kelvin) around 1851:

Where α is the angle between the direction of magnetization and the direction of current flow.

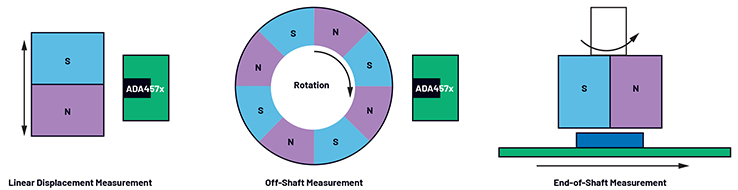

For an optimal sensor response in linear displacement measurements, the sensor is placed such that the magnet and the sensor are in the same plane and the center of the magnet is in line with the center of the sensor. Because an AMR sensor cannot distinguish between north and south poles, the position of the magnet cannot be changed.

For rotating elements, so-called off-shaft or end-of-shaft configurations are common. In the example with the off-shaft configuration (see Figure 1), the sensor sine/cosine outputs repeat the absolute information for every pole—for example, 45° for a 4-pole pair magnet.

In the end-of-shaft configuration (see Figure 1), the sensor is situated below a rotating dipole magnet; here, the north and south poles form a uniform field above the center of the magnet. The sensor is positioned in such a way that the magnetic field and the element to be measured are in the same plane. A typical application is rotor position measurement and control in brushless DC motors. In the case of AMR sensors, which are characteristically 180° angle sensors, the motor must be an even pole pair-motor; motors with an odd number of pole pairs require 360° information for commutation. Compared with conventional Hall sensors, which are also used in motor control, AMR sensors such as the ADA4570 and the ADA4571 have a higher precision. They also reduce the torque ripple and provide true power on absolute position information after startup or an idle state irrespective of the motor position.

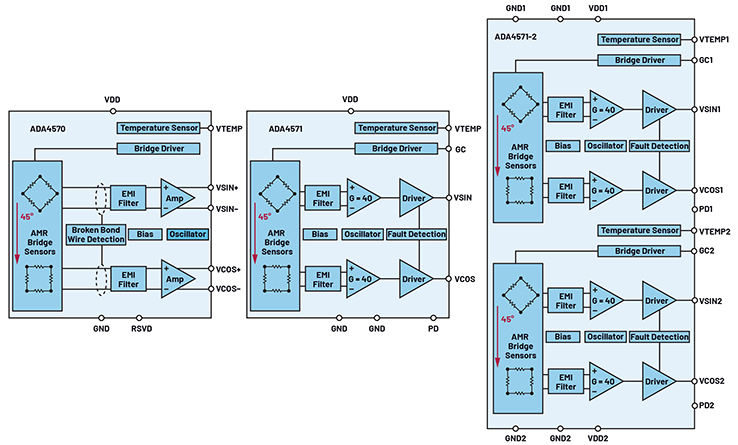

The AMR technology from Analog Devices measures the angle by means of two Wheatstone bridges with one rotated by 45° with respect to the other (see Figure 2). The angle is calculated via sine and cosine functions and represents the orientation from 0° to 180° in relation to the sensor (ADA4570).

In AMR sensors, differentiation is made between electrical angles and mechanical angles. Due to the working principle of AMR sensors and the above-described

45° angle between the Wheatstone bridges, the absolute angle can be measured by means of Equation 2 over 180° mechanical rotation. The electrical period repeats twice over the 360° rotation for a dipole magnet. Given that AMR sensors work in saturation, the absolute field strength is irrelevant with a certain minimum magnetic field strength present allowing for robust systems when working with strong magnets.

Apart from optical sensors, Hall sensors, and resolvers, magnetic sensors provide a further elegant solution for measuring position with high precision and robustness in many different applications. Analog Devices offers a number of possibilities for this, such as the ADA4570, ADA4571, and ADA4571-2 where redundancy is needed. To find out more about this topic, please see the references listed at the end of this article.

References

Guyol, Robert. “AN-1314 Application Note: AMR Angle Sensors.” Analog Devices, Inc., October 2014.

Nicholl, Enda. “Dual AMR Motor Position Sensor for Safety Critical Applications.” Analog Dialogue, Vol. 53, No. 4, November 2019.

About the Author: Benjamin Reiss has been working at Analog Devices in Munich, Germany since April 2017. He graduated in 2016 from the Friedrich-Alexander University in Erlangen with a master’s degree in nanotechnology. After completion of the trainee program at © Analog Devices, he joined the regional team as a field applications engineer supporting several broad market accounts. He can be reached at benjamin.reiss@analog.com.