© SKC

Business |

South Korean semiconductor giant expands with new US plant

SKC, a part of South Korean conglomerate SK Group, says it will build a 12,000 square metre production plant in Georgia, U.S. by 2023 and is already planning an expansion.

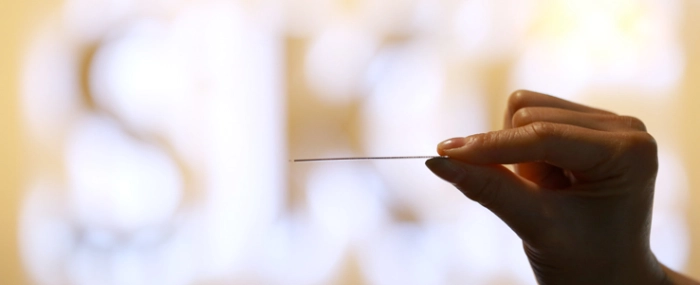

SKC is starting to commercialise high-performance computing glass substrate that it has developed. Glass substrate is described as a futuristic material that is considered a 'game changer' in the semiconductor packaging field as it can significantly increase the performance and power efficiency of computer chipsets.

The company has now decided to build a semiconductor glass substrate production base within the premises of SKC inc. in Georgia, USA by investing a total of USD 80 million, including a technology value of USD 70 million. The current plan is to complete the 12,000 square metre mass production facilities by 2023, a press release from the company reads.

SKC's glass substrate for high performance computing (HPC) is expected to change the game for semiconductor packages. When a glass substrate is applied, the package thickness is cut in half and so is power consumption. In general, semiconductors such as CPU, GPU, and memory are packaged as one component on a substrate together with several MLCCs before being connected to a PCB. Plastic substrates were widely used, but as described by SKC, their uneven surface turned problematic for high-performance semiconductor packaging involving repetitive miniaturisation. An alternative method was developed in which silicon with a smooth surface was used as an intermediate substrate (interposer).

However, compared to a glass substrate, this method has low efficiency and limited uses; The package gets thicker due to an interposer, making it hard to be used for mobile applications; The increased distance between the semiconductor chip and the PCB results in larger power consumption, too. In addition, it is difficult to economically produce large-area rectangular substrates required for high performance in round silicon. Which is why glass substrate is an attractive solution.

SKC says in the press release that it is considering expanding the production capacity to 72,000 square meters per year by 2025, given that the semiconductor packaging market for high-performance computing is rapidly growing due to a surge in data throughput such as AI and data center servers.

"SKC's glass substrates are receiving great attention from global semiconductor material suppliers and semiconductor manufacturers alike as they are produced with the groundbreaking technology that enables chip designers to achieve the maximum performance they can ever aspire to,” An unnamed SKC official says in the press release, adding. “We will build a stable business base in collaboration with our business partners so we supply our innovative products to global semiconductor manufacturers while contributing to innovations across the industry using high-performance semiconductors.”