© Analog Devices Inc.

Application Notes |

Ultralow noise, 48V, phantom microphone power supply using a tiny DC-to-DC boost converter

Question: Can I produce a compact, ultralow noise, phantom power supply (48 V) from a 5 V, 12 V, or 24 V input?

Answer: You can, using a simple boost converter, a filter circuit to reduce EMI, and a little trickery to keep the size small.

Professional condenser microphones require a 48 V supply to charge the internal capacitive transducer and power the internal buffer for the high impedance transducer output. This supply is low current, typically only a few mA, but it must be very low noise because the microphone’s output levels are quite low and the buffer doesn’t have very good power supply ripple rejection. In addition, the phantom supply must not inject EMI into adjacent low level circuits, which is always a challenge in tightly packed products.

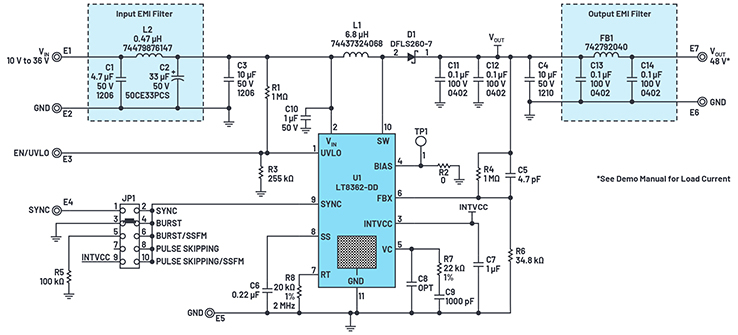

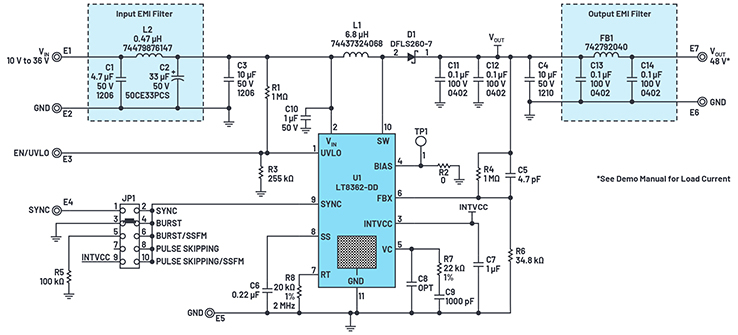

Figure 1. Schematic of demonstration circuit DC2628 used to build a phantom power supply.

A very high performance supply can be built using the LT8362 boost converter, which features a 60 V, 2 A switch and is capable of running at frequencies up to 2 MHz, all in a package as small as 3 mm × 3 mm. The circuit presented here is based on the standard LT8362 demo board DC2628A, the schematic of which is shown in Figure 1.

The input EMI filter on the demo board does a good job of taking care of high frequency noise, aided by the switching inductor, which appears in series with the input. The situation is not as good on the output. The output EMI filter effectively suppresses noise in the MHz region, but has little effect on noise in the audio range. This noise mostly arises due to the 30× gain in the feedback loop amplifying the reference noise of the LT8362.

Figure 1. Schematic of demonstration circuit DC2628 used to build a phantom power supply.

A very high performance supply can be built using the LT8362 boost converter, which features a 60 V, 2 A switch and is capable of running at frequencies up to 2 MHz, all in a package as small as 3 mm × 3 mm. The circuit presented here is based on the standard LT8362 demo board DC2628A, the schematic of which is shown in Figure 1.

The input EMI filter on the demo board does a good job of taking care of high frequency noise, aided by the switching inductor, which appears in series with the input. The situation is not as good on the output. The output EMI filter effectively suppresses noise in the MHz region, but has little effect on noise in the audio range. This noise mostly arises due to the 30× gain in the feedback loop amplifying the reference noise of the LT8362.

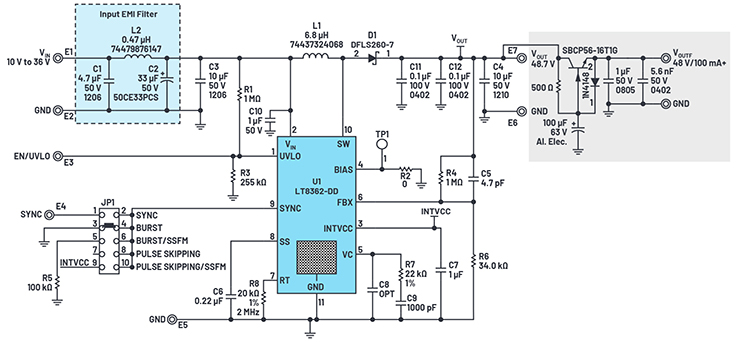

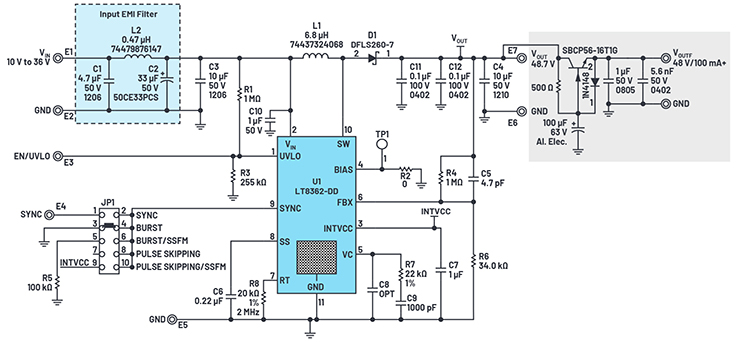

Figure 2. The same circuit as Figure 1, but with a capacitance multiplier (gray) at the output to suppress audio frequency noise produced by the switching regulator.

One approach to cure this noise is to add capacitance at the output. Given enough capacitance this would work, but with a 48 V output, the lowest practical capacitor working voltage of 63 V means that the required caps are both big and expensive. A second approach would be to increase the LT8362 output a volt or two and add an LDO regulator to the output. This requires a high voltage LDO regulator, which usually costs more than the low voltage counterpart. In addition, while these regulators can have low noise at lower output voltages, devices that use a voltage reference also suffer from the same reference noise multiplication issue as the LT8362.

Figure 2. The same circuit as Figure 1, but with a capacitance multiplier (gray) at the output to suppress audio frequency noise produced by the switching regulator.

One approach to cure this noise is to add capacitance at the output. Given enough capacitance this would work, but with a 48 V output, the lowest practical capacitor working voltage of 63 V means that the required caps are both big and expensive. A second approach would be to increase the LT8362 output a volt or two and add an LDO regulator to the output. This requires a high voltage LDO regulator, which usually costs more than the low voltage counterpart. In addition, while these regulators can have low noise at lower output voltages, devices that use a voltage reference also suffer from the same reference noise multiplication issue as the LT8362.

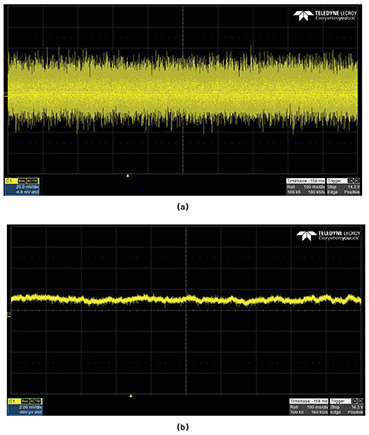

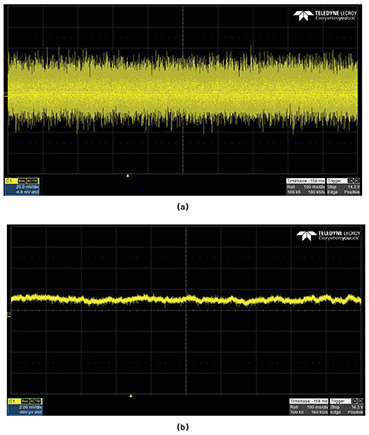

Figure 3. Before and after filter. (a) The output of the boost regulator presents about 0.2% noise content when measured at C4 (before filter). (b) The post-filter output contains a much improved 0.002% noise content.

A third approach is to take advantage of the fact that the sensitivity of the microphone output is not highly dependent on the supply voltage, so the phantom supply does not require perfect regulation. This means we can put some resistance in series with the output caps to increase their effectiveness; however, this only partly mitigates the size of the high voltage caps.

A better approach is to make the output capacitors seem bigger than they really are. This can be accomplished with an old school technique called capacitance multiplication. This simple circuit can be seen in the gray shaded area of Figure 2.

Here, the 100 µF cap controls the ripple on the base current, so its effect on the collector current is amplified by the beta of the NPN transistor. The effect is dramatic. Figure 3a shows the output of the LT8362 circuit at C4 (before the filter) with a 1 kΩ load (50 mA).

The noise is roughly 80 mV p-p, which represents about 0.2% noise content. While this may be sufficient for noncritical applications, the output after the filter is substantially better at approximately 1 mV p-p, as shown in Figure 3b. This represents about 0.002% or 20 ppm noise content—sufficient for even the most demanding applications. Figure 4 shows the benchtop setup.

Figure 3. Before and after filter. (a) The output of the boost regulator presents about 0.2% noise content when measured at C4 (before filter). (b) The post-filter output contains a much improved 0.002% noise content.

A third approach is to take advantage of the fact that the sensitivity of the microphone output is not highly dependent on the supply voltage, so the phantom supply does not require perfect regulation. This means we can put some resistance in series with the output caps to increase their effectiveness; however, this only partly mitigates the size of the high voltage caps.

A better approach is to make the output capacitors seem bigger than they really are. This can be accomplished with an old school technique called capacitance multiplication. This simple circuit can be seen in the gray shaded area of Figure 2.

Here, the 100 µF cap controls the ripple on the base current, so its effect on the collector current is amplified by the beta of the NPN transistor. The effect is dramatic. Figure 3a shows the output of the LT8362 circuit at C4 (before the filter) with a 1 kΩ load (50 mA).

The noise is roughly 80 mV p-p, which represents about 0.2% noise content. While this may be sufficient for noncritical applications, the output after the filter is substantially better at approximately 1 mV p-p, as shown in Figure 3b. This represents about 0.002% or 20 ppm noise content—sufficient for even the most demanding applications. Figure 4 shows the benchtop setup.

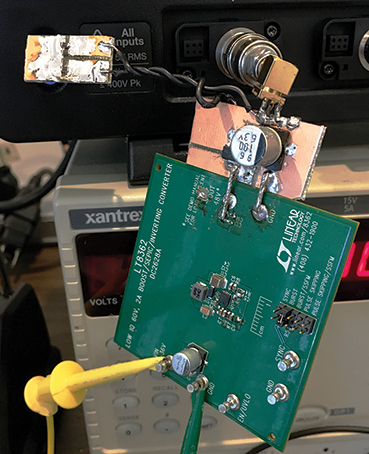

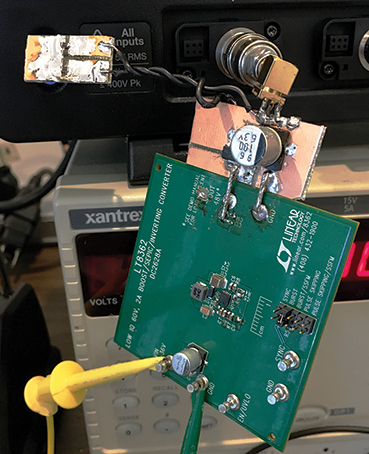

Figure 4. Benchtop setup of a clean phantom power supply using demonstration circuit DC2628.

The transistor SBCP56-16T1G was chosen for high VCBEO (80 V) and high beta at low currents. The high beta gives the capacitance multiplier high apparent capacitance and relatively constant drop as output current varies.

The output voltage drops from 47.8 V with a 2 kΩ load to 47.5 V at 500 Ω load, which is sufficient for microphone applications. Do not substitute another transistor without testing for noise and regulation.

The tests were run with 16 V input, but the performance will be similar with 12 V to 24 VIN. Some applications may require boosting from 5 V, which can be accomplished by decreasing the LT8362’s switching frequency from 2 MHz to 1 MHz to allow for the 75 ns minimum off time.

This would also require increasing L1 to about 10 µH to 15 µH and doubling up on bulk output cap C4 to maintain equivalent performance.

References

Figure 4. Benchtop setup of a clean phantom power supply using demonstration circuit DC2628.

The transistor SBCP56-16T1G was chosen for high VCBEO (80 V) and high beta at low currents. The high beta gives the capacitance multiplier high apparent capacitance and relatively constant drop as output current varies.

The output voltage drops from 47.8 V with a 2 kΩ load to 47.5 V at 500 Ω load, which is sufficient for microphone applications. Do not substitute another transistor without testing for noise and regulation.

The tests were run with 16 V input, but the performance will be similar with 12 V to 24 VIN. Some applications may require boosting from 5 V, which can be accomplished by decreasing the LT8362’s switching frequency from 2 MHz to 1 MHz to allow for the 75 ns minimum off time.

This would also require increasing L1 to about 10 µH to 15 µH and doubling up on bulk output cap C4 to maintain equivalent performance.

References

About the Authors: Thomas Mosteller was a field applications engineer for Analog Devices' Mid-Atlantic region starting in 1990. He assisted a wide range of military, commercial, and industrial customers with designs in many fields such as power distribution and supplies, analog signal conditioning, data conversion, and RF and communications applications. Prior to joining Linear Technology (now Analog Devices), Thomas designed a wide range of medical equipment for 10 years and holds a patent in the design of infusion pumps. He earned a B.S.E.E. degree from Drexel University in 1977. Christopher Jarboe received his B.S.E.E. from Western Kentucky University in 2005 and joined Linear Technology (now © Analog Devices Inc.) in 2010. He is an applications engineer supporting customers in the Northeast and Mid-Atlantic United States. He can be reached at christopher.jarboe@analog.com.

Figure 1. Schematic of demonstration circuit DC2628 used to build a phantom power supply.

A very high performance supply can be built using the LT8362 boost converter, which features a 60 V, 2 A switch and is capable of running at frequencies up to 2 MHz, all in a package as small as 3 mm × 3 mm. The circuit presented here is based on the standard LT8362 demo board DC2628A, the schematic of which is shown in Figure 1.

The input EMI filter on the demo board does a good job of taking care of high frequency noise, aided by the switching inductor, which appears in series with the input. The situation is not as good on the output. The output EMI filter effectively suppresses noise in the MHz region, but has little effect on noise in the audio range. This noise mostly arises due to the 30× gain in the feedback loop amplifying the reference noise of the LT8362.

Figure 1. Schematic of demonstration circuit DC2628 used to build a phantom power supply.

A very high performance supply can be built using the LT8362 boost converter, which features a 60 V, 2 A switch and is capable of running at frequencies up to 2 MHz, all in a package as small as 3 mm × 3 mm. The circuit presented here is based on the standard LT8362 demo board DC2628A, the schematic of which is shown in Figure 1.

The input EMI filter on the demo board does a good job of taking care of high frequency noise, aided by the switching inductor, which appears in series with the input. The situation is not as good on the output. The output EMI filter effectively suppresses noise in the MHz region, but has little effect on noise in the audio range. This noise mostly arises due to the 30× gain in the feedback loop amplifying the reference noise of the LT8362.

Figure 2. The same circuit as Figure 1, but with a capacitance multiplier (gray) at the output to suppress audio frequency noise produced by the switching regulator.

One approach to cure this noise is to add capacitance at the output. Given enough capacitance this would work, but with a 48 V output, the lowest practical capacitor working voltage of 63 V means that the required caps are both big and expensive. A second approach would be to increase the LT8362 output a volt or two and add an LDO regulator to the output. This requires a high voltage LDO regulator, which usually costs more than the low voltage counterpart. In addition, while these regulators can have low noise at lower output voltages, devices that use a voltage reference also suffer from the same reference noise multiplication issue as the LT8362.

Figure 2. The same circuit as Figure 1, but with a capacitance multiplier (gray) at the output to suppress audio frequency noise produced by the switching regulator.

One approach to cure this noise is to add capacitance at the output. Given enough capacitance this would work, but with a 48 V output, the lowest practical capacitor working voltage of 63 V means that the required caps are both big and expensive. A second approach would be to increase the LT8362 output a volt or two and add an LDO regulator to the output. This requires a high voltage LDO regulator, which usually costs more than the low voltage counterpart. In addition, while these regulators can have low noise at lower output voltages, devices that use a voltage reference also suffer from the same reference noise multiplication issue as the LT8362.

Figure 3. Before and after filter. (a) The output of the boost regulator presents about 0.2% noise content when measured at C4 (before filter). (b) The post-filter output contains a much improved 0.002% noise content.

A third approach is to take advantage of the fact that the sensitivity of the microphone output is not highly dependent on the supply voltage, so the phantom supply does not require perfect regulation. This means we can put some resistance in series with the output caps to increase their effectiveness; however, this only partly mitigates the size of the high voltage caps.

A better approach is to make the output capacitors seem bigger than they really are. This can be accomplished with an old school technique called capacitance multiplication. This simple circuit can be seen in the gray shaded area of Figure 2.

Here, the 100 µF cap controls the ripple on the base current, so its effect on the collector current is amplified by the beta of the NPN transistor. The effect is dramatic. Figure 3a shows the output of the LT8362 circuit at C4 (before the filter) with a 1 kΩ load (50 mA).

The noise is roughly 80 mV p-p, which represents about 0.2% noise content. While this may be sufficient for noncritical applications, the output after the filter is substantially better at approximately 1 mV p-p, as shown in Figure 3b. This represents about 0.002% or 20 ppm noise content—sufficient for even the most demanding applications. Figure 4 shows the benchtop setup.

Figure 3. Before and after filter. (a) The output of the boost regulator presents about 0.2% noise content when measured at C4 (before filter). (b) The post-filter output contains a much improved 0.002% noise content.

A third approach is to take advantage of the fact that the sensitivity of the microphone output is not highly dependent on the supply voltage, so the phantom supply does not require perfect regulation. This means we can put some resistance in series with the output caps to increase their effectiveness; however, this only partly mitigates the size of the high voltage caps.

A better approach is to make the output capacitors seem bigger than they really are. This can be accomplished with an old school technique called capacitance multiplication. This simple circuit can be seen in the gray shaded area of Figure 2.

Here, the 100 µF cap controls the ripple on the base current, so its effect on the collector current is amplified by the beta of the NPN transistor. The effect is dramatic. Figure 3a shows the output of the LT8362 circuit at C4 (before the filter) with a 1 kΩ load (50 mA).

The noise is roughly 80 mV p-p, which represents about 0.2% noise content. While this may be sufficient for noncritical applications, the output after the filter is substantially better at approximately 1 mV p-p, as shown in Figure 3b. This represents about 0.002% or 20 ppm noise content—sufficient for even the most demanding applications. Figure 4 shows the benchtop setup.

Figure 4. Benchtop setup of a clean phantom power supply using demonstration circuit DC2628.

The transistor SBCP56-16T1G was chosen for high VCBEO (80 V) and high beta at low currents. The high beta gives the capacitance multiplier high apparent capacitance and relatively constant drop as output current varies.

The output voltage drops from 47.8 V with a 2 kΩ load to 47.5 V at 500 Ω load, which is sufficient for microphone applications. Do not substitute another transistor without testing for noise and regulation.

The tests were run with 16 V input, but the performance will be similar with 12 V to 24 VIN. Some applications may require boosting from 5 V, which can be accomplished by decreasing the LT8362’s switching frequency from 2 MHz to 1 MHz to allow for the 75 ns minimum off time.

This would also require increasing L1 to about 10 µH to 15 µH and doubling up on bulk output cap C4 to maintain equivalent performance.

References

Figure 4. Benchtop setup of a clean phantom power supply using demonstration circuit DC2628.

The transistor SBCP56-16T1G was chosen for high VCBEO (80 V) and high beta at low currents. The high beta gives the capacitance multiplier high apparent capacitance and relatively constant drop as output current varies.

The output voltage drops from 47.8 V with a 2 kΩ load to 47.5 V at 500 Ω load, which is sufficient for microphone applications. Do not substitute another transistor without testing for noise and regulation.

The tests were run with 16 V input, but the performance will be similar with 12 V to 24 VIN. Some applications may require boosting from 5 V, which can be accomplished by decreasing the LT8362’s switching frequency from 2 MHz to 1 MHz to allow for the 75 ns minimum off time.

This would also require increasing L1 to about 10 µH to 15 µH and doubling up on bulk output cap C4 to maintain equivalent performance.

References

- Nelson, Carl. Application Note 19: LT1070 Design Manual. Analog Devices, Inc., June 1986.

- Williams, Jim. Application Note 101: Minimizing Switching Regulator Residue in Linear Regulator Outputs. Analog Devices, Inc., July 2005.

About the Authors: Thomas Mosteller was a field applications engineer for Analog Devices' Mid-Atlantic region starting in 1990. He assisted a wide range of military, commercial, and industrial customers with designs in many fields such as power distribution and supplies, analog signal conditioning, data conversion, and RF and communications applications. Prior to joining Linear Technology (now Analog Devices), Thomas designed a wide range of medical equipment for 10 years and holds a patent in the design of infusion pumps. He earned a B.S.E.E. degree from Drexel University in 1977. Christopher Jarboe received his B.S.E.E. from Western Kentucky University in 2005 and joined Linear Technology (now © Analog Devices Inc.) in 2010. He is an applications engineer supporting customers in the Northeast and Mid-Atlantic United States. He can be reached at christopher.jarboe@analog.com.