© Analog Devices Inc.

Application Notes |

Overvoltage protection for RTD-based measurement ysstems

Question: Is it possible to design a complete RTD module with overvoltage protection?

Answer: RTD (resistance temperature detectors) can provide excellent stability and accuracy, and reduce the impacts of noise and interference. RTD sensors can be made up of either 2-wire, 3-wire, or 4-wire versions, and require an excitation current to produce an output voltage. AD7124-4/AD7124-8 contain two well matched current sources, a PGA, reference buffers, and diagnostic functions, which are ideally suited for high reliability RTD modules.

Incorrect operations, careless connections, and exposed wires usually lead to overvoltage faults in industrial circumstances, which will damage the electronic devices and cause undesirable consequences that may flow from the damage. Overvoltage protection ability is a key specification for an RTD module. Outside of transient overvoltage protection, durable overvoltage protection must be considered during actual production.

This article will focus on hot to provide a total solution for multiwire RTD modules with overvoltage protection function, which is based on AD7124, and overvoltage protection and detection multiplexers and channel protectors. This article can help designers understand this method and choose appropriate devices. For overvoltage protection functions, here are three optional solutions:

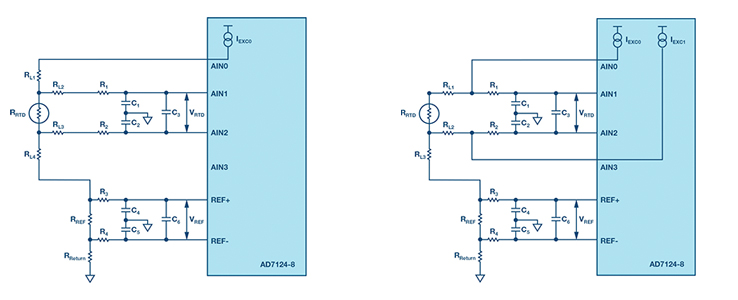

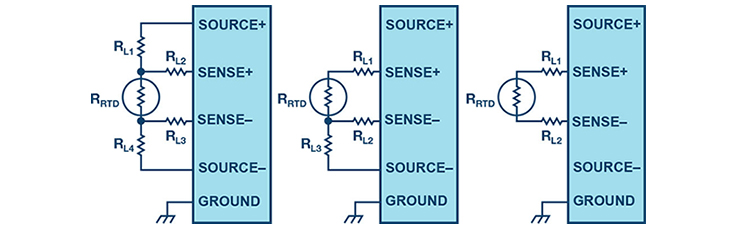

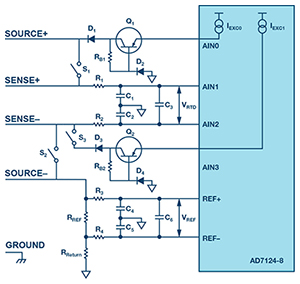

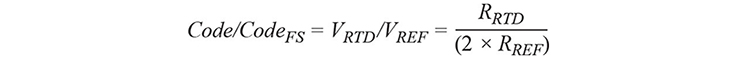

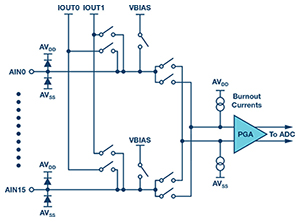

Figure 1. 4-wire RTD ratiometric measurement based on AD7124-8.

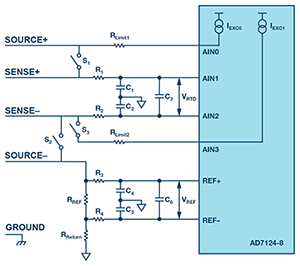

Figure 2. 3-wire RTD ratiometric measurement based on AD7124-8.

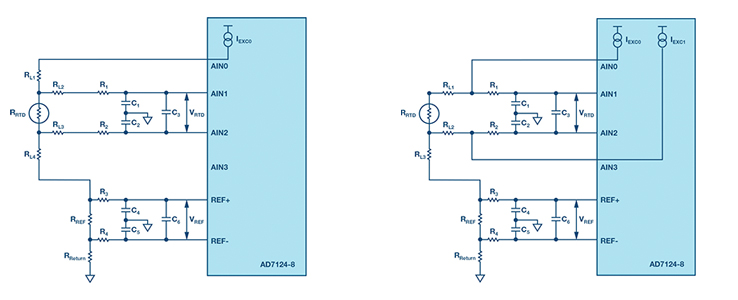

By using a 4-wire RTD configuration, the system can achieve high accuracy and reliability and the error due to lead wire resistance can be removed. Accordingly, the cost is higher than a 3-wire or 2-wire configuration. Figure 2 shows the 3-wire RTD measurement based on AD7124, which is a compromise between performance and cost.

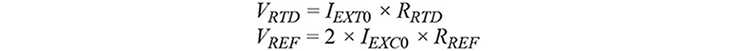

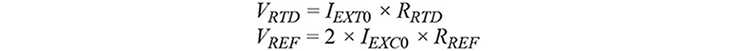

Two integrated, well matched current sources are helpful for 3-wire RTD measurement. VREF and VRTD can be expressed by the following two functions:

Figure 1. 4-wire RTD ratiometric measurement based on AD7124-8.

Figure 2. 3-wire RTD ratiometric measurement based on AD7124-8.

By using a 4-wire RTD configuration, the system can achieve high accuracy and reliability and the error due to lead wire resistance can be removed. Accordingly, the cost is higher than a 3-wire or 2-wire configuration. Figure 2 shows the 3-wire RTD measurement based on AD7124, which is a compromise between performance and cost.

Two integrated, well matched current sources are helpful for 3-wire RTD measurement. VREF and VRTD can be expressed by the following two functions:

AD7124 has two well matched current sources, which means IEXC0 is near or equal to IEXC1 and the lead resistors RL1 and RL2 are very similar. The functions can be expressed as:

AD7124 has two well matched current sources, which means IEXC0 is near or equal to IEXC1 and the lead resistors RL1 and RL2 are very similar. The functions can be expressed as:

Express the conversion code as a composition of these two functions:

Express the conversion code as a composition of these two functions:

According to this function, the RTD resistor value can be calculated by the conversion result and reference resistor value. Please refer to CN-0383 for details.

According to this function, the RTD resistor value can be calculated by the conversion result and reference resistor value. Please refer to CN-0383 for details.

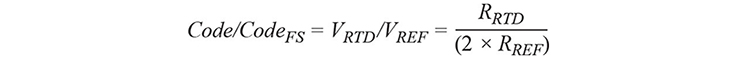

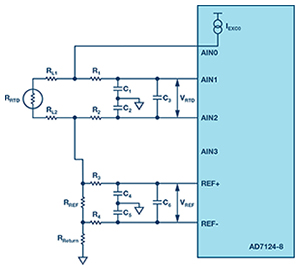

Figure 3. 2-wire RTD ratiometric measurement based on AD7124-8.

For a 2-wire RTD, the error due to lead resistance can’t be cancelled, but the cost of these type RTD sensors is lower than the others, and AD7124-8 can be configured as a 2-wire RTD sensor, as seen in Figure 3.

In practice, many industrial customers ask for the same port of an RTD module to many different types of RTD sensors, which is convenient for balancing RTD sensors’ cost and performance. Figure 4 shows a universal interface of an RTD module, which can support different wires RTD sensors.

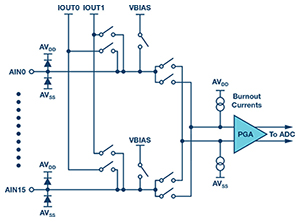

Due to this requirement, this type of RTD module needs to be configured by firmware for differently wired RTD sensors easily. Figure 5 shows the block diagram for different wire RTD sensors based on one piece of the AD7124-8 and its switches. AD7124-8 can support a 4-channel, 2-wire/3-wire/4-wire RTD measurement.

Figure 3. 2-wire RTD ratiometric measurement based on AD7124-8.

For a 2-wire RTD, the error due to lead resistance can’t be cancelled, but the cost of these type RTD sensors is lower than the others, and AD7124-8 can be configured as a 2-wire RTD sensor, as seen in Figure 3.

In practice, many industrial customers ask for the same port of an RTD module to many different types of RTD sensors, which is convenient for balancing RTD sensors’ cost and performance. Figure 4 shows a universal interface of an RTD module, which can support different wires RTD sensors.

Due to this requirement, this type of RTD module needs to be configured by firmware for differently wired RTD sensors easily. Figure 5 shows the block diagram for different wire RTD sensors based on one piece of the AD7124-8 and its switches. AD7124-8 can support a 4-channel, 2-wire/3-wire/4-wire RTD measurement.

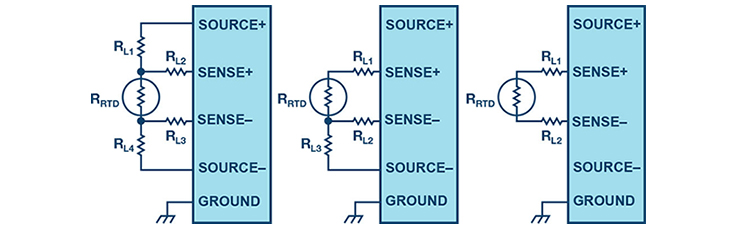

Figure 4. RTD interface for different wire sensors.

Using a controller can change the configuration for different sensors easily, and Table 1 shows switches and current source status for different configurations.

Table 1. Switch and IEXT Status for Different Wire RTD Sensors

Figure 4. RTD interface for different wire sensors.

Using a controller can change the configuration for different sensors easily, and Table 1 shows switches and current source status for different configurations.

Table 1. Switch and IEXT Status for Different Wire RTD Sensors

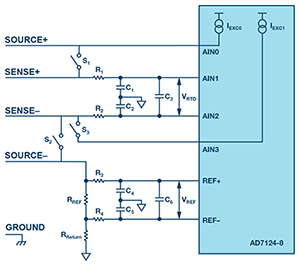

Figure 5. Different wire RTD sensors measurement based on AD7124-8.

Choosing appropriate resistor and capacitor value by calculation can optimize the noise performance. The article Analog Front-End Design Considerations for RTD Ratiometric Temperature Measurements can provide guidance. If, in addition to an optimized noise performance, overvoltage protection is needed in the field, the additional requirement will cause a lot of additional trouble.

First, some analog pins of AD7124 are directly exposed to outside environments, and according to the absolute maximum ratings of AD7124 under 25°C, the analog input voltage to AVSS should between −0.3 V to AVDD +0.3 V, which means this module can’t defend high overvoltage occur. Secondly, three switches need to bear high voltage.

Adding Current Limiting Resistors

Adding current limiting resistors on every pin of AD7124 can provide overvoltage protection for AD7124 easily.

Figure 5. Different wire RTD sensors measurement based on AD7124-8.

Choosing appropriate resistor and capacitor value by calculation can optimize the noise performance. The article Analog Front-End Design Considerations for RTD Ratiometric Temperature Measurements can provide guidance. If, in addition to an optimized noise performance, overvoltage protection is needed in the field, the additional requirement will cause a lot of additional trouble.

First, some analog pins of AD7124 are directly exposed to outside environments, and according to the absolute maximum ratings of AD7124 under 25°C, the analog input voltage to AVSS should between −0.3 V to AVDD +0.3 V, which means this module can’t defend high overvoltage occur. Secondly, three switches need to bear high voltage.

Adding Current Limiting Resistors

Adding current limiting resistors on every pin of AD7124 can provide overvoltage protection for AD7124 easily.

Figure 6. AD7124-8 analog pin internal architecture.

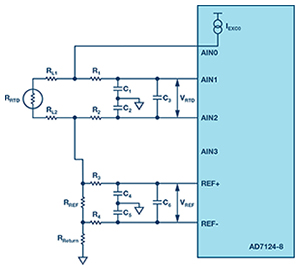

Figure 6 shows the AD7124 analog pin architecture. There are two clamping diodes on every analog pin and we can use these diodes to implement protection directly without introducing any other leakage current.

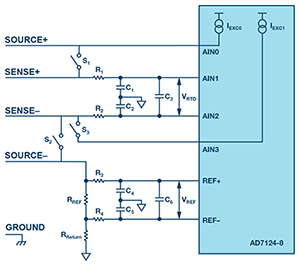

Figure 7 shows the diagram of this method—R1 to R4 are in front of AIN1, AIN2, REF+, and REF– separately. This setup is used for noise elimination. These resistors can be used for current limit at the same time and adding current limiting resistors in front of AIN0 and AIN3 can protect the rest of exposed analog pins of AD7124.

Figure 6. AD7124-8 analog pin internal architecture.

Figure 6 shows the AD7124 analog pin architecture. There are two clamping diodes on every analog pin and we can use these diodes to implement protection directly without introducing any other leakage current.

Figure 7 shows the diagram of this method—R1 to R4 are in front of AIN1, AIN2, REF+, and REF– separately. This setup is used for noise elimination. These resistors can be used for current limit at the same time and adding current limiting resistors in front of AIN0 and AIN3 can protect the rest of exposed analog pins of AD7124.

Figure 7. Adding current limiting resistors in front of ADC input pins.

These resistors and the internal clamping diodes can protect against some level of positive and negative overvoltage. When positive or negative overvoltage fault occurs, the current will flow through the resistors and internal clamping diodes to AVDD or AVSS. The current value must be limited to less than 10 mA, according to the absolute specification of AD7124. If RLimit is equal to 3 kΩ, this module can prevent ±30 V durable overvoltage.

However, there would be a voltage drop on RLIMIT when this module works in a normal mode. If the excitation current was 500 μA, the voltage drop on RLIMIT would be 1.5 V, the resistance of sensor and RREF would be limited. Increasing RLIMIT can get better protection, but the resistance range will be smaller. The compliance voltage will decrease along with the increasing overvoltage protection requirement based on this protection method. If the power consumption of RREF and RReturn is taken care of, the fault voltage will directly drop on these two resistors.

Except for AD7124-8 analog pins, the switches are exposed under the high voltage too, so we should choose the parts that can defend ±30 V voltage. In the past few years, photo MOS and relay have been used in these situations, but the high price and large package limit the sphere of application.

Using Discrete Transistors to Protect the Current Source

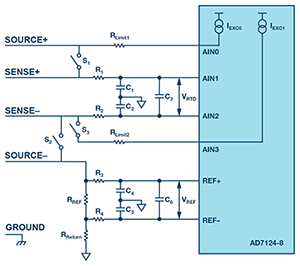

The biggest weakness of using limit resistors is that the compliance voltage on SOURCE+ is low. Using discrete transistors and diodes can implement overvoltage protection and increase the max allowed voltage on SOURCE+ pin. Figure 8 shows the diagram for this method.

Figure 7. Adding current limiting resistors in front of ADC input pins.

These resistors and the internal clamping diodes can protect against some level of positive and negative overvoltage. When positive or negative overvoltage fault occurs, the current will flow through the resistors and internal clamping diodes to AVDD or AVSS. The current value must be limited to less than 10 mA, according to the absolute specification of AD7124. If RLimit is equal to 3 kΩ, this module can prevent ±30 V durable overvoltage.

However, there would be a voltage drop on RLIMIT when this module works in a normal mode. If the excitation current was 500 μA, the voltage drop on RLIMIT would be 1.5 V, the resistance of sensor and RREF would be limited. Increasing RLIMIT can get better protection, but the resistance range will be smaller. The compliance voltage will decrease along with the increasing overvoltage protection requirement based on this protection method. If the power consumption of RREF and RReturn is taken care of, the fault voltage will directly drop on these two resistors.

Except for AD7124-8 analog pins, the switches are exposed under the high voltage too, so we should choose the parts that can defend ±30 V voltage. In the past few years, photo MOS and relay have been used in these situations, but the high price and large package limit the sphere of application.

Using Discrete Transistors to Protect the Current Source

The biggest weakness of using limit resistors is that the compliance voltage on SOURCE+ is low. Using discrete transistors and diodes can implement overvoltage protection and increase the max allowed voltage on SOURCE+ pin. Figure 8 shows the diagram for this method.

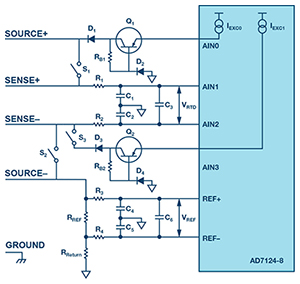

Figure 8. Using discrete transistors and diodes for overvoltage protection.

This architecture can keep the excitation current flow to the RTD sensor in a normal situation and defend against high overvoltage damage. The other analog input pins can be protected by current limiting resistors, since analog input pins have no compliance voltage limitation.

If a large positive voltage is applied to this RTD sensor, D1 prevents the current source from positive high voltage. If a large negative voltage is applied to this RTD sensor, the PN junction between Q1’s collector and base is in reverse biased, causing high voltage drops on RB1 and this PN junction, which can prevent damage to AIN0.

In the normal mode, D2 functions as a reverse biased diode, which keeps the current flow through this part very small. There is very little current flow throw Q1’s emitter to base, so the voltage drop on RB1 can be neglectful. This method can keep compliance voltage higher than using current limiting resistors and defend much higher fault voltage.

Using Analog Switches and Multiplexers with Overvoltage Protection Function

The weaknesses of using discrete components to protect this high precision RTD module are obvious—it’s not easy to choose appropriate components; these parts makes the protection circuit complicated; and they occupy a large PCB area.

Even though the leakage current of AD7124 analog input pins is quite small, the large resistor series on these pins, such as R1 and R2, will produce notable error, and the thermal noise of these resistors decrease the resolution. In an actual design, the RTD module may have multiple channels, the current source would switch from one channel to the other, a large resistor value increases the settling time of analog input RC combination, and a RTD module should spend more time on charging the capacitors, such as C1, C2, and C3. It’s hard to balance protection functions and accuracy. And the switches still need to protect against high overvoltage too.

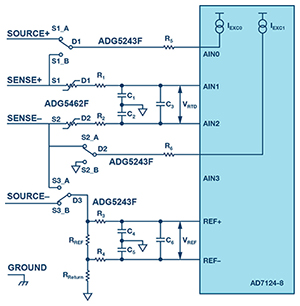

In this case, using analog switches and multiplexers with fault protection can provide switch and overvoltage protection. Figure 9 shows an example.

Figure 8. Using discrete transistors and diodes for overvoltage protection.

This architecture can keep the excitation current flow to the RTD sensor in a normal situation and defend against high overvoltage damage. The other analog input pins can be protected by current limiting resistors, since analog input pins have no compliance voltage limitation.

If a large positive voltage is applied to this RTD sensor, D1 prevents the current source from positive high voltage. If a large negative voltage is applied to this RTD sensor, the PN junction between Q1’s collector and base is in reverse biased, causing high voltage drops on RB1 and this PN junction, which can prevent damage to AIN0.

In the normal mode, D2 functions as a reverse biased diode, which keeps the current flow through this part very small. There is very little current flow throw Q1’s emitter to base, so the voltage drop on RB1 can be neglectful. This method can keep compliance voltage higher than using current limiting resistors and defend much higher fault voltage.

Using Analog Switches and Multiplexers with Overvoltage Protection Function

The weaknesses of using discrete components to protect this high precision RTD module are obvious—it’s not easy to choose appropriate components; these parts makes the protection circuit complicated; and they occupy a large PCB area.

Even though the leakage current of AD7124 analog input pins is quite small, the large resistor series on these pins, such as R1 and R2, will produce notable error, and the thermal noise of these resistors decrease the resolution. In an actual design, the RTD module may have multiple channels, the current source would switch from one channel to the other, a large resistor value increases the settling time of analog input RC combination, and a RTD module should spend more time on charging the capacitors, such as C1, C2, and C3. It’s hard to balance protection functions and accuracy. And the switches still need to protect against high overvoltage too.

In this case, using analog switches and multiplexers with fault protection can provide switch and overvoltage protection. Figure 9 shows an example.

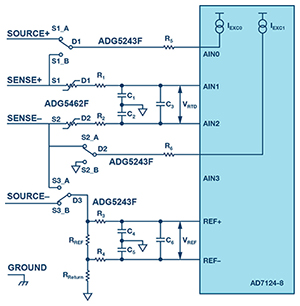

Figure 9. Analog switches and multiplexers with fault protection.

In Figure 9, there are three SPDT switches using the ADG5243F in front of the AD7124, and two variable resistors using ADG5462F in front of AIN1 and AIN2. These components can be implemented by using ADG5243F and ADG5462F, which have user-defined fault protection and detection functions. The highlight feature of these parts are:

Figure 9. Analog switches and multiplexers with fault protection.

In Figure 9, there are three SPDT switches using the ADG5243F in front of the AD7124, and two variable resistors using ADG5462F in front of AIN1 and AIN2. These components can be implemented by using ADG5243F and ADG5462F, which have user-defined fault protection and detection functions. The highlight feature of these parts are:

Author: Yao Zhao [yao.zhao@analog.com] has worked as a product application engineer with the China design center in ADI Beijing. He is responsible for the technical support for precision Σ-Δ ADC products across China. © Analog Devices. Inc.

- Using series resistors in front of the pins of an ADC can help protect the AD7124 easily. These pins include analog input and excitation output pins, but the resistors will limit compliance voltage.

- The protection of current source can be realized by discrete components. This solution can achieve higher overvoltage protection and larger voltage compliance. However, the switches and multiplexers are still externally exposed.

- ADI’s overvoltage protection and detection switches, multiplexers, and channel protectors (ADG52xxF and ADG54xxF) can be used for RTD module protection and different wires RTD sensor switching. These parts can provide ±55 V fault voltage protection in both the powered and unpowered mode, and can implement fault detection with latch-up immunity. Their high density package occupies a much smaller PCB area than traditional solutions.

Figure 1. 4-wire RTD ratiometric measurement based on AD7124-8.

Figure 2. 3-wire RTD ratiometric measurement based on AD7124-8.

By using a 4-wire RTD configuration, the system can achieve high accuracy and reliability and the error due to lead wire resistance can be removed. Accordingly, the cost is higher than a 3-wire or 2-wire configuration. Figure 2 shows the 3-wire RTD measurement based on AD7124, which is a compromise between performance and cost.

Two integrated, well matched current sources are helpful for 3-wire RTD measurement. VREF and VRTD can be expressed by the following two functions:

Figure 1. 4-wire RTD ratiometric measurement based on AD7124-8.

Figure 2. 3-wire RTD ratiometric measurement based on AD7124-8.

By using a 4-wire RTD configuration, the system can achieve high accuracy and reliability and the error due to lead wire resistance can be removed. Accordingly, the cost is higher than a 3-wire or 2-wire configuration. Figure 2 shows the 3-wire RTD measurement based on AD7124, which is a compromise between performance and cost.

Two integrated, well matched current sources are helpful for 3-wire RTD measurement. VREF and VRTD can be expressed by the following two functions:

AD7124 has two well matched current sources, which means IEXC0 is near or equal to IEXC1 and the lead resistors RL1 and RL2 are very similar. The functions can be expressed as:

AD7124 has two well matched current sources, which means IEXC0 is near or equal to IEXC1 and the lead resistors RL1 and RL2 are very similar. The functions can be expressed as:

Express the conversion code as a composition of these two functions:

Express the conversion code as a composition of these two functions:

According to this function, the RTD resistor value can be calculated by the conversion result and reference resistor value. Please refer to CN-0383 for details.

According to this function, the RTD resistor value can be calculated by the conversion result and reference resistor value. Please refer to CN-0383 for details.

Figure 3. 2-wire RTD ratiometric measurement based on AD7124-8.

For a 2-wire RTD, the error due to lead resistance can’t be cancelled, but the cost of these type RTD sensors is lower than the others, and AD7124-8 can be configured as a 2-wire RTD sensor, as seen in Figure 3.

In practice, many industrial customers ask for the same port of an RTD module to many different types of RTD sensors, which is convenient for balancing RTD sensors’ cost and performance. Figure 4 shows a universal interface of an RTD module, which can support different wires RTD sensors.

Due to this requirement, this type of RTD module needs to be configured by firmware for differently wired RTD sensors easily. Figure 5 shows the block diagram for different wire RTD sensors based on one piece of the AD7124-8 and its switches. AD7124-8 can support a 4-channel, 2-wire/3-wire/4-wire RTD measurement.

Figure 3. 2-wire RTD ratiometric measurement based on AD7124-8.

For a 2-wire RTD, the error due to lead resistance can’t be cancelled, but the cost of these type RTD sensors is lower than the others, and AD7124-8 can be configured as a 2-wire RTD sensor, as seen in Figure 3.

In practice, many industrial customers ask for the same port of an RTD module to many different types of RTD sensors, which is convenient for balancing RTD sensors’ cost and performance. Figure 4 shows a universal interface of an RTD module, which can support different wires RTD sensors.

Due to this requirement, this type of RTD module needs to be configured by firmware for differently wired RTD sensors easily. Figure 5 shows the block diagram for different wire RTD sensors based on one piece of the AD7124-8 and its switches. AD7124-8 can support a 4-channel, 2-wire/3-wire/4-wire RTD measurement.

Figure 4. RTD interface for different wire sensors.

Using a controller can change the configuration for different sensors easily, and Table 1 shows switches and current source status for different configurations.

Table 1. Switch and IEXT Status for Different Wire RTD Sensors

Figure 4. RTD interface for different wire sensors.

Using a controller can change the configuration for different sensors easily, and Table 1 shows switches and current source status for different configurations.

Table 1. Switch and IEXT Status for Different Wire RTD Sensors

| S1 | S2 | S3 | IETX1 | IETX2 | |

| 2-wire RTD | Closed | Closed | Open | Enable | Disable |

| 3-wire RTD | Closed | Open | Closed | Enable | Enable |

| 4-wire RTF | Open | Open | Open | Enable | Disable |

Figure 5. Different wire RTD sensors measurement based on AD7124-8.

Choosing appropriate resistor and capacitor value by calculation can optimize the noise performance. The article Analog Front-End Design Considerations for RTD Ratiometric Temperature Measurements can provide guidance. If, in addition to an optimized noise performance, overvoltage protection is needed in the field, the additional requirement will cause a lot of additional trouble.

First, some analog pins of AD7124 are directly exposed to outside environments, and according to the absolute maximum ratings of AD7124 under 25°C, the analog input voltage to AVSS should between −0.3 V to AVDD +0.3 V, which means this module can’t defend high overvoltage occur. Secondly, three switches need to bear high voltage.

Adding Current Limiting Resistors

Adding current limiting resistors on every pin of AD7124 can provide overvoltage protection for AD7124 easily.

Figure 5. Different wire RTD sensors measurement based on AD7124-8.

Choosing appropriate resistor and capacitor value by calculation can optimize the noise performance. The article Analog Front-End Design Considerations for RTD Ratiometric Temperature Measurements can provide guidance. If, in addition to an optimized noise performance, overvoltage protection is needed in the field, the additional requirement will cause a lot of additional trouble.

First, some analog pins of AD7124 are directly exposed to outside environments, and according to the absolute maximum ratings of AD7124 under 25°C, the analog input voltage to AVSS should between −0.3 V to AVDD +0.3 V, which means this module can’t defend high overvoltage occur. Secondly, three switches need to bear high voltage.

Adding Current Limiting Resistors

Adding current limiting resistors on every pin of AD7124 can provide overvoltage protection for AD7124 easily.

Figure 6. AD7124-8 analog pin internal architecture.

Figure 6 shows the AD7124 analog pin architecture. There are two clamping diodes on every analog pin and we can use these diodes to implement protection directly without introducing any other leakage current.

Figure 7 shows the diagram of this method—R1 to R4 are in front of AIN1, AIN2, REF+, and REF– separately. This setup is used for noise elimination. These resistors can be used for current limit at the same time and adding current limiting resistors in front of AIN0 and AIN3 can protect the rest of exposed analog pins of AD7124.

Figure 6. AD7124-8 analog pin internal architecture.

Figure 6 shows the AD7124 analog pin architecture. There are two clamping diodes on every analog pin and we can use these diodes to implement protection directly without introducing any other leakage current.

Figure 7 shows the diagram of this method—R1 to R4 are in front of AIN1, AIN2, REF+, and REF– separately. This setup is used for noise elimination. These resistors can be used for current limit at the same time and adding current limiting resistors in front of AIN0 and AIN3 can protect the rest of exposed analog pins of AD7124.

Figure 7. Adding current limiting resistors in front of ADC input pins.

These resistors and the internal clamping diodes can protect against some level of positive and negative overvoltage. When positive or negative overvoltage fault occurs, the current will flow through the resistors and internal clamping diodes to AVDD or AVSS. The current value must be limited to less than 10 mA, according to the absolute specification of AD7124. If RLimit is equal to 3 kΩ, this module can prevent ±30 V durable overvoltage.

However, there would be a voltage drop on RLIMIT when this module works in a normal mode. If the excitation current was 500 μA, the voltage drop on RLIMIT would be 1.5 V, the resistance of sensor and RREF would be limited. Increasing RLIMIT can get better protection, but the resistance range will be smaller. The compliance voltage will decrease along with the increasing overvoltage protection requirement based on this protection method. If the power consumption of RREF and RReturn is taken care of, the fault voltage will directly drop on these two resistors.

Except for AD7124-8 analog pins, the switches are exposed under the high voltage too, so we should choose the parts that can defend ±30 V voltage. In the past few years, photo MOS and relay have been used in these situations, but the high price and large package limit the sphere of application.

Using Discrete Transistors to Protect the Current Source

The biggest weakness of using limit resistors is that the compliance voltage on SOURCE+ is low. Using discrete transistors and diodes can implement overvoltage protection and increase the max allowed voltage on SOURCE+ pin. Figure 8 shows the diagram for this method.

Figure 7. Adding current limiting resistors in front of ADC input pins.

These resistors and the internal clamping diodes can protect against some level of positive and negative overvoltage. When positive or negative overvoltage fault occurs, the current will flow through the resistors and internal clamping diodes to AVDD or AVSS. The current value must be limited to less than 10 mA, according to the absolute specification of AD7124. If RLimit is equal to 3 kΩ, this module can prevent ±30 V durable overvoltage.

However, there would be a voltage drop on RLIMIT when this module works in a normal mode. If the excitation current was 500 μA, the voltage drop on RLIMIT would be 1.5 V, the resistance of sensor and RREF would be limited. Increasing RLIMIT can get better protection, but the resistance range will be smaller. The compliance voltage will decrease along with the increasing overvoltage protection requirement based on this protection method. If the power consumption of RREF and RReturn is taken care of, the fault voltage will directly drop on these two resistors.

Except for AD7124-8 analog pins, the switches are exposed under the high voltage too, so we should choose the parts that can defend ±30 V voltage. In the past few years, photo MOS and relay have been used in these situations, but the high price and large package limit the sphere of application.

Using Discrete Transistors to Protect the Current Source

The biggest weakness of using limit resistors is that the compliance voltage on SOURCE+ is low. Using discrete transistors and diodes can implement overvoltage protection and increase the max allowed voltage on SOURCE+ pin. Figure 8 shows the diagram for this method.

Figure 8. Using discrete transistors and diodes for overvoltage protection.

This architecture can keep the excitation current flow to the RTD sensor in a normal situation and defend against high overvoltage damage. The other analog input pins can be protected by current limiting resistors, since analog input pins have no compliance voltage limitation.

If a large positive voltage is applied to this RTD sensor, D1 prevents the current source from positive high voltage. If a large negative voltage is applied to this RTD sensor, the PN junction between Q1’s collector and base is in reverse biased, causing high voltage drops on RB1 and this PN junction, which can prevent damage to AIN0.

In the normal mode, D2 functions as a reverse biased diode, which keeps the current flow through this part very small. There is very little current flow throw Q1’s emitter to base, so the voltage drop on RB1 can be neglectful. This method can keep compliance voltage higher than using current limiting resistors and defend much higher fault voltage.

Using Analog Switches and Multiplexers with Overvoltage Protection Function

The weaknesses of using discrete components to protect this high precision RTD module are obvious—it’s not easy to choose appropriate components; these parts makes the protection circuit complicated; and they occupy a large PCB area.

Even though the leakage current of AD7124 analog input pins is quite small, the large resistor series on these pins, such as R1 and R2, will produce notable error, and the thermal noise of these resistors decrease the resolution. In an actual design, the RTD module may have multiple channels, the current source would switch from one channel to the other, a large resistor value increases the settling time of analog input RC combination, and a RTD module should spend more time on charging the capacitors, such as C1, C2, and C3. It’s hard to balance protection functions and accuracy. And the switches still need to protect against high overvoltage too.

In this case, using analog switches and multiplexers with fault protection can provide switch and overvoltage protection. Figure 9 shows an example.

Figure 8. Using discrete transistors and diodes for overvoltage protection.

This architecture can keep the excitation current flow to the RTD sensor in a normal situation and defend against high overvoltage damage. The other analog input pins can be protected by current limiting resistors, since analog input pins have no compliance voltage limitation.

If a large positive voltage is applied to this RTD sensor, D1 prevents the current source from positive high voltage. If a large negative voltage is applied to this RTD sensor, the PN junction between Q1’s collector and base is in reverse biased, causing high voltage drops on RB1 and this PN junction, which can prevent damage to AIN0.

In the normal mode, D2 functions as a reverse biased diode, which keeps the current flow through this part very small. There is very little current flow throw Q1’s emitter to base, so the voltage drop on RB1 can be neglectful. This method can keep compliance voltage higher than using current limiting resistors and defend much higher fault voltage.

Using Analog Switches and Multiplexers with Overvoltage Protection Function

The weaknesses of using discrete components to protect this high precision RTD module are obvious—it’s not easy to choose appropriate components; these parts makes the protection circuit complicated; and they occupy a large PCB area.

Even though the leakage current of AD7124 analog input pins is quite small, the large resistor series on these pins, such as R1 and R2, will produce notable error, and the thermal noise of these resistors decrease the resolution. In an actual design, the RTD module may have multiple channels, the current source would switch from one channel to the other, a large resistor value increases the settling time of analog input RC combination, and a RTD module should spend more time on charging the capacitors, such as C1, C2, and C3. It’s hard to balance protection functions and accuracy. And the switches still need to protect against high overvoltage too.

In this case, using analog switches and multiplexers with fault protection can provide switch and overvoltage protection. Figure 9 shows an example.

Figure 9. Analog switches and multiplexers with fault protection.

In Figure 9, there are three SPDT switches using the ADG5243F in front of the AD7124, and two variable resistors using ADG5462F in front of AIN1 and AIN2. These components can be implemented by using ADG5243F and ADG5462F, which have user-defined fault protection and detection functions. The highlight feature of these parts are:

Figure 9. Analog switches and multiplexers with fault protection.

In Figure 9, there are three SPDT switches using the ADG5243F in front of the AD7124, and two variable resistors using ADG5462F in front of AIN1 and AIN2. These components can be implemented by using ADG5243F and ADG5462F, which have user-defined fault protection and detection functions. The highlight feature of these parts are:

- The source pins are protected against voltages greater than the secondary supply rails, from –55 V and +55 V.

- The source pins are protected against voltages between –55 V and +55 V in an unpowered state.

- Overvoltage detection with the digital output indicates the operating state of the switches.

- Trench isolation guards against latch-up.

- Optimized for low charge injection and on-capacitance.

- The ADG5243F can be operated from a dual supply of ±5 V to ±22 V or a single power supply of 8 V to 44 V.

- Making RTD modules endure higher fault voltage

- Low leakage current, low noise, and short settling time

- Replacing traditional relay and photo MOS, saving PCB area and cost

- Diagnostic functionality enhances system robustness

- Easy to use

Author: Yao Zhao [yao.zhao@analog.com] has worked as a product application engineer with the China design center in ADI Beijing. He is responsible for the technical support for precision Σ-Δ ADC products across China. © Analog Devices. Inc.