© Analog Devices

Application Notes |

Burned by Low Power? When lower current consumption can get you into trouble

Question: I changed one of my devices to a newer and better part with lower current consumption. Nothing is working anymore and even the new part got “burned.” Do you have any explanation?

Answer:

Linear regulators are fairly simple devices and don’t have too many challenges. With that said, you can still get into trouble with them occasionally.

In my role as a field applications engineer, there are times when customers request me to recommend a drop in replacement for a part they are using from another supplier. In many of these cases, the decision to replace a part is made by the customer’s production/purchase team and the original circuit designer may not be aware of the change. The decision process is fairly simple and the alternative part should have the same functionality, package, and pin configuration, as well as equal or better electrical specifications when compared to the device being replaced. Once all of these boxes are checked, you provide the necessary comparison data to the component engineer and the new component is added to the bill of materials as a second source alternative. After doing that, you should be all set. That is, until the product that was working faithfully with the older component starts failing on the production line after changing over to the alternative. What went wrong?!

I was involved in one such case where we followed the previously mentioned process and got one of our isolated RS-485 transceivers designed in as a second source to another supplier’s device in a customer’s design. The devices were form, fit, and functionality compatible, and our part had better electrical specifications. The customer went ahead and ordered a large quantity of this part from us and there seemed no reason for anything to go wrong. However, the customer reported that the new RS-485 transceiver started failing on the production test bed. Since nothing else in the design had been changed, it came down to something being wrong with the new device in the picture.

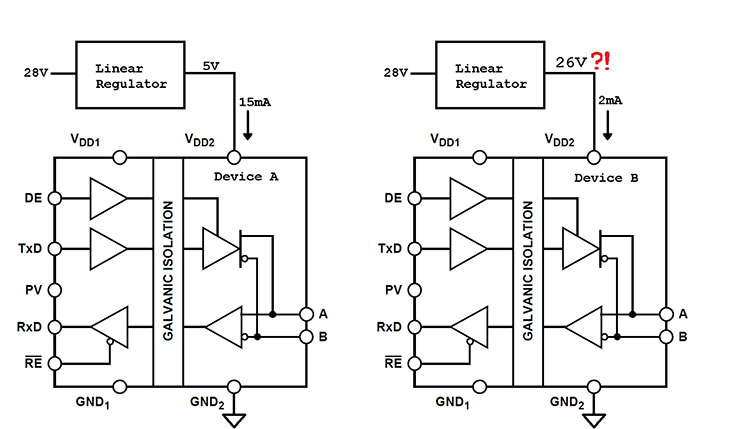

Upon further investigation, we found that the linear regulator powering the bus side of the transceiver was not regulating down to 5 V as expected, but instead was going up to a much higher voltage. We needed to do a careful review and comparison of the data sheets for the older transceiver and the replacement one, as well as the data sheet of the linear regulator to figure out what was going wrong.

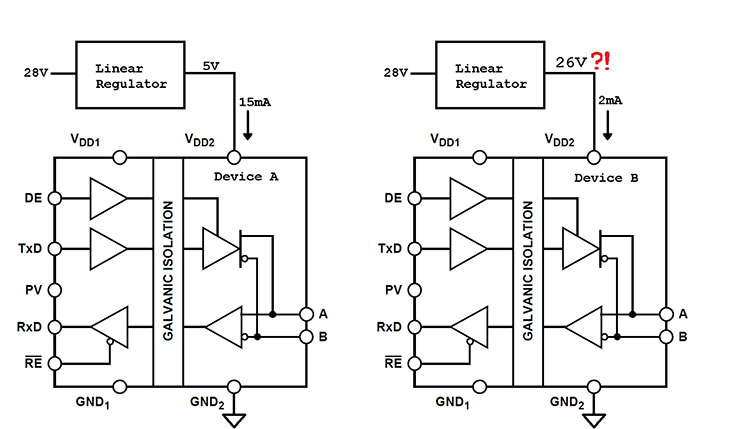

Better is a qualitative term and depends on the parameter in question. For example, when it comes to speed/CMRR/PSRR, higher is better; when it comes to offset voltage/drift, lower is better; and you don’t need great engineering insight to know that when it comes to power consumption, lower is always better. Or is it? In this particular case, it turned out it wasn’t. The older transceiver consumed 15 mA (typically) on the bus side in idle state, while the new device consumed only 2 mA (maximum). It was no wonder that the new device looked better on paper. Unfortunately, the linear regulator didn’t seem to agree and went berserk.

As I mentioned at the start of this article, linear regulators are fairly simple devices that don’t have too many demands. Their one peculiar requirement is that they need a minimum load current to function properly. If this condition is not met, the regulator stops regulating correctly and the output voltage goes out of bounds. The situation could also get worse if the input voltage to the regulator is much higher than the desired output voltage. Read this excellent article for more details on this topic.1

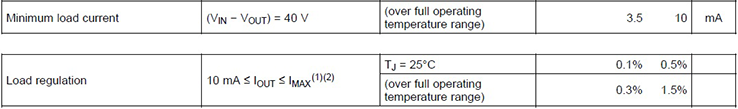

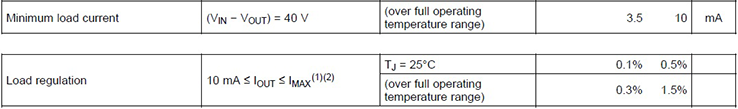

Many modern linear regulators take special care in their design to address this and pose no such problems. Some of the older devices (like the one in the customer’s design) don’t, and, hence, need extra precautions during the system design. In some cases, the feedback resistor network for the adjustable output LDO takes care of the minimum load current. Unfortunately, one could run into this issue inadvertently by deciding to supersize these resistors while keeping the ratio the same. There could also be another scenario in which the device being powered by the LDO meets the load requirement during normal operation, but not while it’s in standby. These are all potential pitfalls to watch out for, so be sure to read the LDO data sheet carefully. If there’s a minimum load current requirement, it would usually say so in some way. Here are a couple of examples:

Figure 1. An example of a minimum load current from a data sheet.

Figure 1. An example of a minimum load current from a data sheet.

Figure 2. Left schematic: the regulator operating correctly with the older device (minimum load current requirement satisfied). Right schematic: the unstable regulator with the new device (load current not sufficient).

Figure 2. Left schematic: the regulator operating correctly with the older device (minimum load current requirement satisfied). Right schematic: the unstable regulator with the new device (load current not sufficient).

Images and graphs: © Analog Devices Inc.

Figure 1. An example of a minimum load current from a data sheet.

Figure 1. An example of a minimum load current from a data sheet.

Figure 2. Left schematic: the regulator operating correctly with the older device (minimum load current requirement satisfied). Right schematic: the unstable regulator with the new device (load current not sufficient).

Figure 2. Left schematic: the regulator operating correctly with the older device (minimum load current requirement satisfied). Right schematic: the unstable regulator with the new device (load current not sufficient).

Going back to our story—once the root cause of the problem was understood, it was fairly simple to fix. All we had to do was add a bleeder resistor on the regulator output to draw the minimum load current. While it would have been easy for an unreasonable customer to blame it on our part, this particular customer could see the funny side of this story and was able to appreciate the technical learning from this episode. It all ended well like any fairy tale—a little blood was spilled, but everyone lived happily ever after. References 1. Luca Vassalli. “Minimum Load Current Operation—Zero-Load Operation.” Analog Dialogue, Vol 48, September, 2014.Figure 3. The problem resolved after adding a bleeder resistor to draw minimum required load current.

Images and graphs: © Analog Devices Inc.